Semi-dried low-protein noodle and preparation method of the semi-dried low-protein noodle

A low-protein noodles, semi-drying technology, applied in the field of food engineering, to achieve the effect of extending shelf life, improving sensory quality, and inhibiting oxidative rancidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

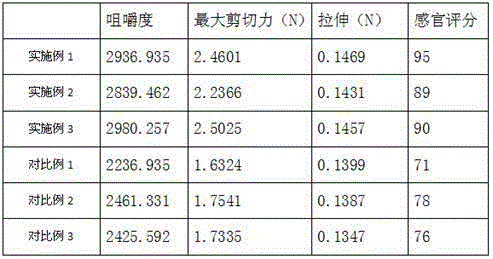

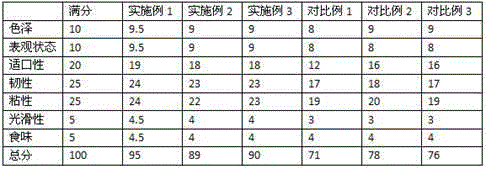

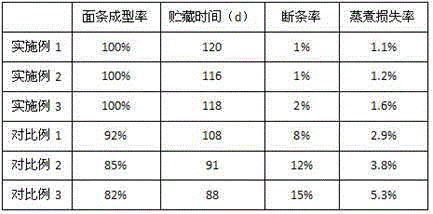

Examples

Embodiment 1

[0029] A semi-dry low-protein noodle, raw material composition: 10 parts of flour, 30 parts of α-modified starch, 40 parts of wheat starch, 0.1 part of sodium carboxymethylcellulose, 0.01 part of phosphate, 0.4 part of lactitol, 0.5 part of glucomannan 0.3 parts of sodium alginate, 8 parts of medicinal and edible plant powder, and 1 part of 75% edible alcohol.

[0030] The preparation method is as follows:

[0031] 1) Weigh medicinal and edible plant powder, add sodium carboxymethylcellulose, phosphate, lactitol, glucomannan and sodium alginate and mix evenly, add water 3 times the mass of raw materials, stir for 4 minutes, and use The colloid mill was stabilized for 4 minutes to obtain a uniform liquid slurry;

[0032] 2) Weigh flour, α-modified starch and wheat starch, add the above uniform liquid slurry, stir for 3 minutes, then add edible alcohol and water to make the moisture content in the raw materials 33%, stir for 12 minutes, cover with plastic wrap , proofed and ma...

Embodiment 2

[0036] A semi-dry low-protein noodle, raw material composition: 10 parts of flour, 20 parts of α-modified starch, 30 parts of wheat starch, 0.05 part of sodium carboxymethylcellulose, 0.01 part of phosphate, 0.3 part of lactitol, 0.3 part of glucomannan 0.2 part of sodium alginate, 7 parts of medicinal and edible plant powder, 0.5 part of edible alcohol;

[0037] The preparation method is as follows:

[0038] 1) Weigh medicinal and edible plant powder, add sodium carboxymethylcellulose, phosphate, lactitol, glucomannan and sodium alginate and mix evenly, add water 3 times the mass of raw materials, stir for 2 minutes, and use The colloid mill was stabilized for 3 minutes to obtain a uniform liquid slurry;

[0039]2) Weigh flour, α-modified starch and wheat starch, add the above-mentioned uniform liquid slurry, stir for 2 minutes, then add edible alcohol and water to make the moisture content in the raw materials 30%, stir for 10 minutes, cover with plastic wrap , proofed and...

Embodiment 3

[0043] A semi-dry low-protein noodle, raw material composition: 30 parts of flour, 30 parts of α-modified starch, 50 parts of wheat starch, 0.2 part of sodium carboxymethylcellulose, 0.03 part of phosphate, 0.5 part of lactitol, 0.6 part of glucomannan 0.4 parts of sodium alginate, 10 parts of medicinal and edible plant powder, and 2 parts of edible alcohol;

[0044] The preparation method is as follows:

[0045] 1) Weigh medicinal and edible plant powder, add sodium carboxymethylcellulose, phosphate, lactitol, glucomannan and sodium alginate and mix evenly, add water 3 times the mass of raw materials, stir for 5 minutes, and use The colloid mill was stabilized for 5 minutes to obtain a uniform liquid slurry;

[0046] 2) Weigh flour, α-modified starch and wheat starch, add the above uniform liquid slurry, stir for 5 minutes, then add edible alcohol and water to make the moisture content in the raw materials 35%, stir for 15 minutes, cover with plastic wrap , proofed and matu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com