Full-automatic fried bread stick forming machine

A molding machine, fully automatic technology, applied in baking, baking workshop, food science and other directions, can solve the problems of requiring a lot of labor, the production process of fried dough sticks cannot be completely completed, and the labor intensity is high.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be further described below in conjunction with the embodiment that accompanying drawing provides.

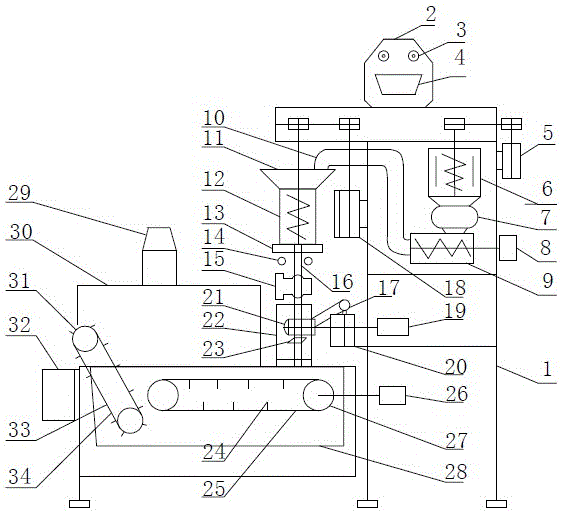

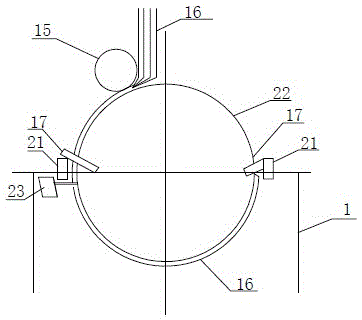

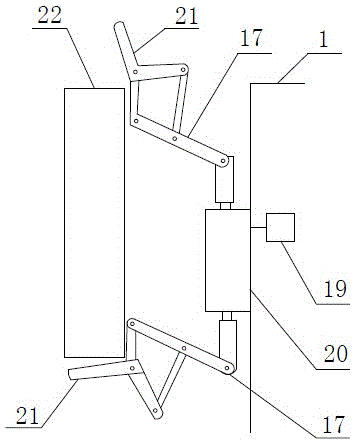

[0038] see figure 1 , this full-automatic deep-fried dough stick forming machine that the present embodiment provides, is made up of frame 1 and main control platform 2 fixed on frame 1, main frame and fryer 28, and frame 1 is also provided with joint surface Mechanism, dough rapid proofing device 7, kneading dough output mechanism 9, extruding mechanism, stretching mechanism and cutting mechanism; The kneading dough output mechanism 9 is connected to the kneading dough output mechanism 9 through the dough fast proofing device 7; Extrusion mechanism 12; Extrusion mechanism 12 is provided with hopper 11, extrusion output disk 13, extrusion mechanism is driven by motor 18, dough is input into extrusion mechanism 12 by hopper 11 and then extruded into noodle bar by extrusion output disk 13 16 output; the bottom of the extruded output disc 13 is p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com