Water-based evaporation drying type gravure ink composition applicable to multiple base materials

A technology of volatilizing drying, gravure ink, applied in the direction of ink, application, household appliances, etc., can solve the problems of high energy consumption of screen ink, endangering the health of operators, injury to operators, etc., to solve the problems of stability and ink drying performance Inadequate aspects, beneficial effects on human health and environmental safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

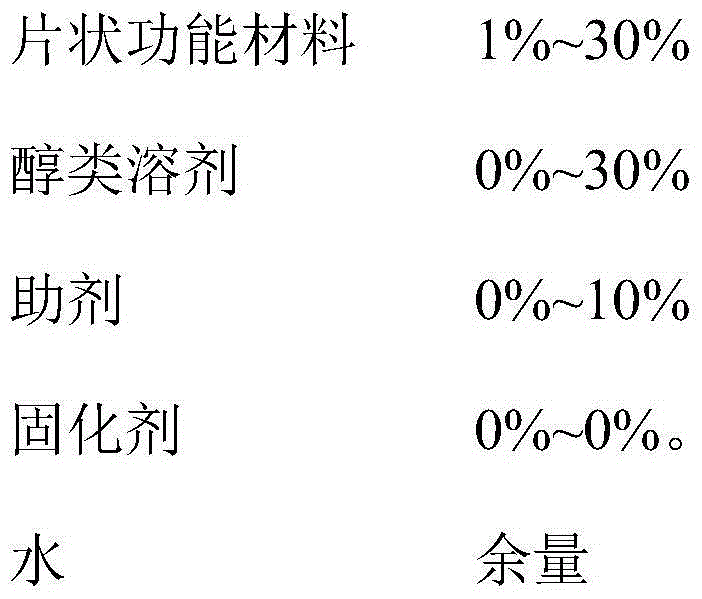

[0026] The formula is shown in the table below, and the amounts of the components are all percentages by weight.

[0027]

[0028]

[0029] Preparation method: First, stir and disperse acrylic emulsion, polyurethane emulsion, thickener and defoamer to make pre-emulsion, then add pearlescent pigment, dispersant, leveling agent, solvent, water, stir and disperse, add curing agent Bayhydur before use 304, stirred to disperse, ready to use.

[0030] The prepared water-based pearlescent gravure ink has a viscosity of 21s (25°C, 2# Chai's cup).

[0031] Use this ink to use white cardboard as the base material, and print in the last color of a ten-color gravure printing machine. The printing speed is 60m / min. The ink has good stability on the machine, the ink dries quickly, and the printed pattern is clear. The printed product adopts the national standard GBT7707- 2008 "Gravure Decorative Printing" conducted ink fastness testing, the results are as follows:

[0032] Bonding f...

Embodiment 2

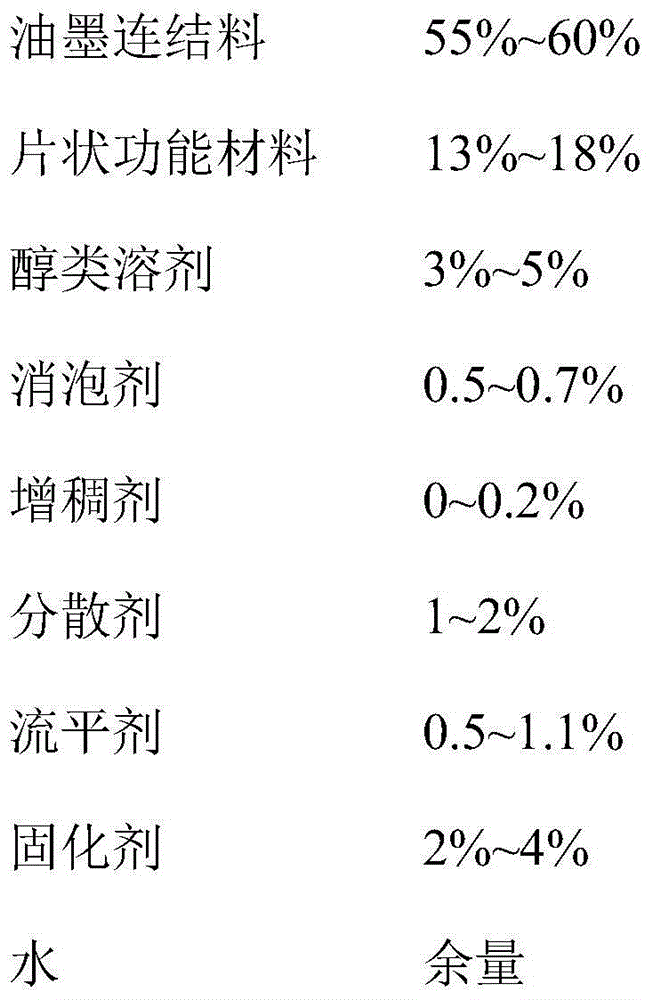

[0042] The formula is shown in the table below, and the amounts of the components are all percentages by weight.

[0043]

[0044]Preparation method: First, stir and disperse acrylic emulsion, polyurethane emulsion, thickener and defoamer to make pre-emulsion, then add pearlescent pigment, dispersant, leveling agent, solvent, water, stir and disperse, add curing agent Basonat before use HW 180PC, stir to disperse, ready to use.

[0045] The prepared water-based pearlescent gravure ink has a viscosity of 22s (25°C, 2# Chai's cup).

[0046] Use this ink to use PET as the base material, print on a monochrome gravure printing machine, the printing speed is 60m / min, the ink has good stability on the machine, the ink dries quickly, and the printed pattern is clear. The printed product adopts the national standard GBT7707-2008 "Gravure Decoration "Print" was tested for the fastness of the ink layer, and the results are as follows:

[0047] Bonding fastness: the area of the ink...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com