A non-anchored ground wire operation method for transmission lines

A technology of transmission lines and ground wires, applied in the direction of overhead lines/cable equipment, etc., can solve problems such as delaying power outages, affecting construction progress, labor and time consumption, etc., to reduce time spent, save labor costs, and speed up construction progress Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

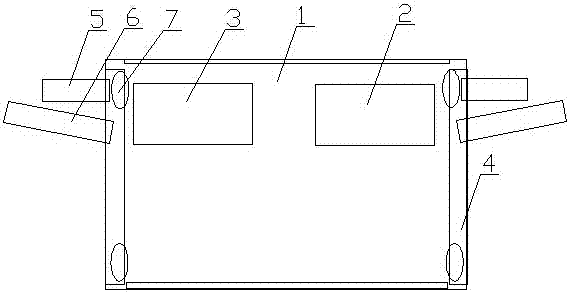

[0033] figure 1It is a schematic diagram of the structure of the ground wire work platform of the present invention. The ground wire work platform is used for tightening and fixing the ground wire. The work platform includes a platform body 1, and a hardware fitting box 2 and accessories are arranged on the platform body 1. In the placing box 3 , brackets 4 are arranged on both sides of the platform body 1 , the wire tensioner 5 and the wire catcher 6 are arranged on the bracket 4 , and a hanging ring 7 is arranged on the platform body 1 . The ground wire working platform is a working platform designed for changing a linear tower to a tensile tower. The platform includes a platform body, and there are guardrails around the body to protect the staff when they are working in the air. The platform body is provided with a hardware placement box and an accessory placement box, which can place the necessary parts during line reconstruction. The wire tensioners and wire clamps set on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com