Energization wire combustion experiment device capable of automatically igniting and collecting smoke and method

A technology of automatic ignition and experimental equipment, applied in the direction of sampling equipment, chemical analysis by combustion, etc., can solve the problems of manual operation, inability to obtain wire fire dynamic flame smoke particles, flame interference, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

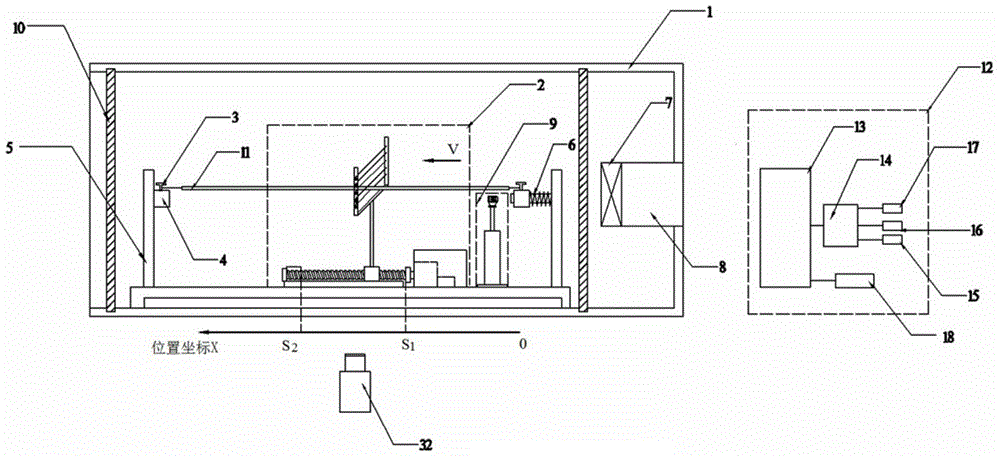

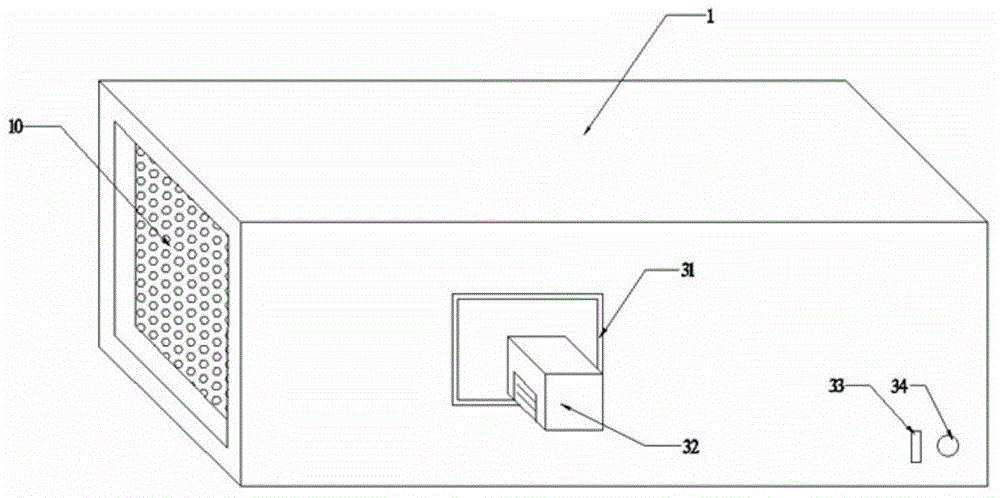

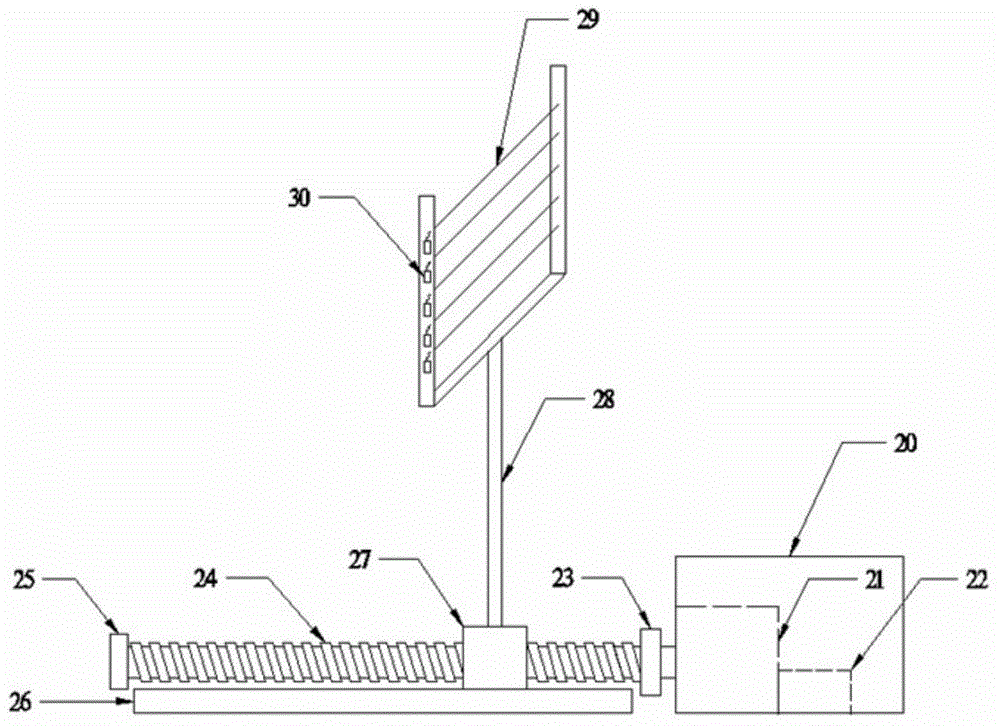

[0061] Such as figure 1 and figure 2 As shown, the present invention includes a combustion chamber 1 and a control center 12 in two parts. The combustion chamber 1 includes a sample table 5, an automatic smoke particle collection device 2, an automatic ignition device 9, and a forced convection generating device. The combustion chamber 1 is a cuboid with an opening at its left end, a circular air inlet on the right wall, a rectangular observation window 31 on the front wall, and a camera 32 fixed by the window for real-time monitoring of the combustion process of the sample wire 11; The lower corner is provided with a fan switch 33 and a wind speed adjustment knob 34 . The control center 12 is used to realize the automatic control of each device in the combustion chamber 1, and its hardware block diagram is as follows: Figure 5 Shown: the computer 13 is connected with the camera 32; the computer 13 is connected with the single-chip microcomputer 14, and the three interfac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com