A high temperature heat storage valley energy utilization device using magnesia iron bricks to encapsulate molten salt

A technology of magnesia-iron bricks and electric heating devices, applied in heat storage equipment, heat storage heaters, fluid heaters, etc., can solve the problem of low thermal conductivity of phase change materials, decreased system heat transfer efficiency, and slow charging and discharging rates and other issues, to achieve the effect of increasing heat storage, improving heat exchange efficiency, and increasing speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] In order to make the purpose, technical solution and advantages of the present invention more clearly described, the present invention will be further described in detail below with reference to the accompanying drawings and examples.

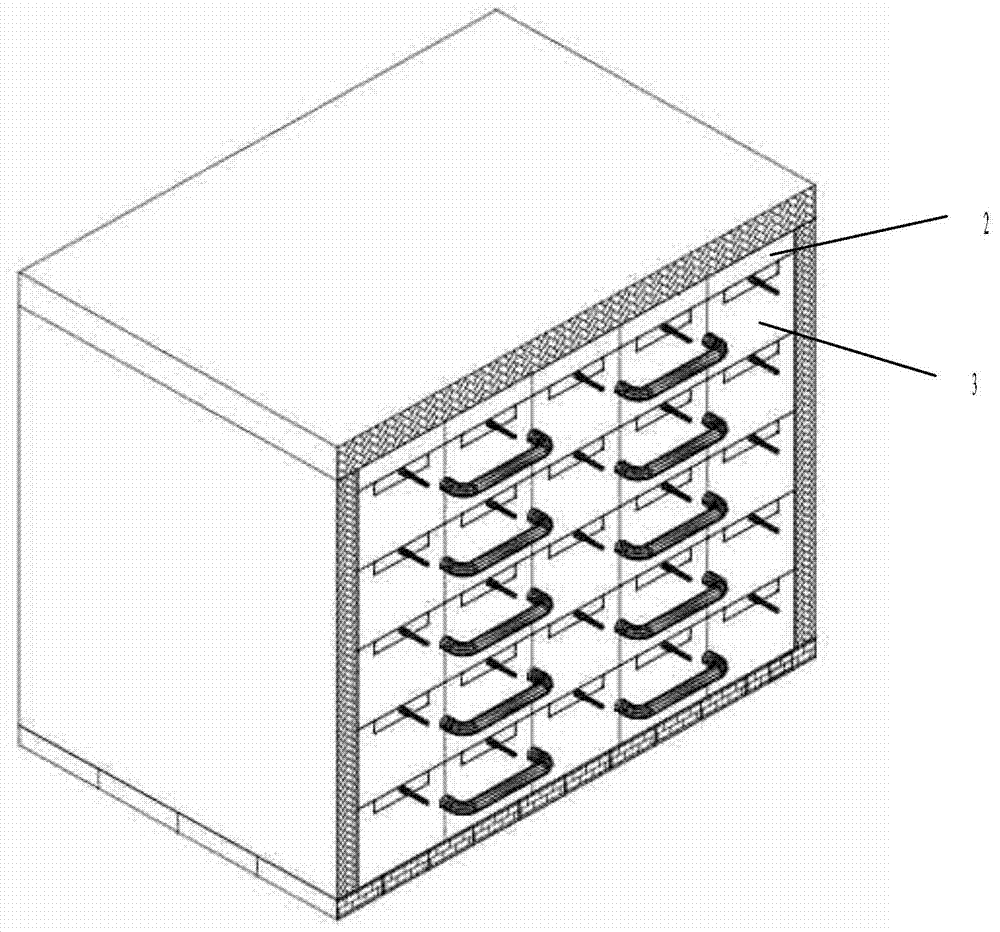

[0042] Such as figure 1 As shown, in this embodiment, the high-temperature heat storage valley energy utilization device using magnesia-iron bricks to encapsulate molten salt is composed of three parts, which are the heat storage pile constructed by the sensible-latent heat storage unit, and the power plant using valley electricity as the heat source. A heating unit and a heat exchange unit for realizing heat extraction. Specifically, each part is as follows:

[0043] Regenerative pile: including sensible-latent heat storage unit 3, the heat storage unit includes prefabricated solid heat storage brick 12 and molten salt unit 13, the main material of solid heat storage brick 12 is clay, magnesium iron and other metal materials powder or ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| freezing point | aaaaa | aaaaa |

| freezing point | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com