Seal joint used for connecting bamboo-like prestressing force flat mouth plastic pipe with bolts and exhaust pipe

A technology for sealing joints and flat-mouthed pipes, which is applied in the direction of pipes/pipe joints/fittings, pipe connection layout, mechanical equipment, etc. The method is cumbersome and other problems, to achieve the effect of simple structure, optimized grouting position, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

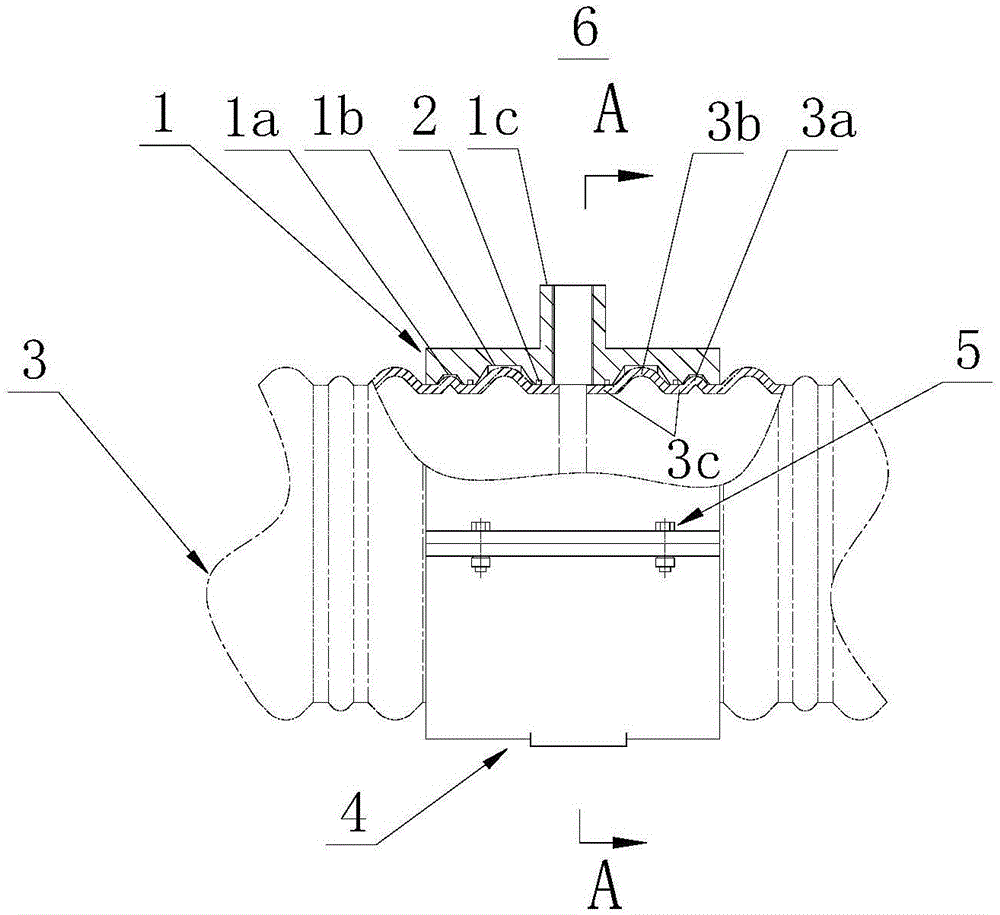

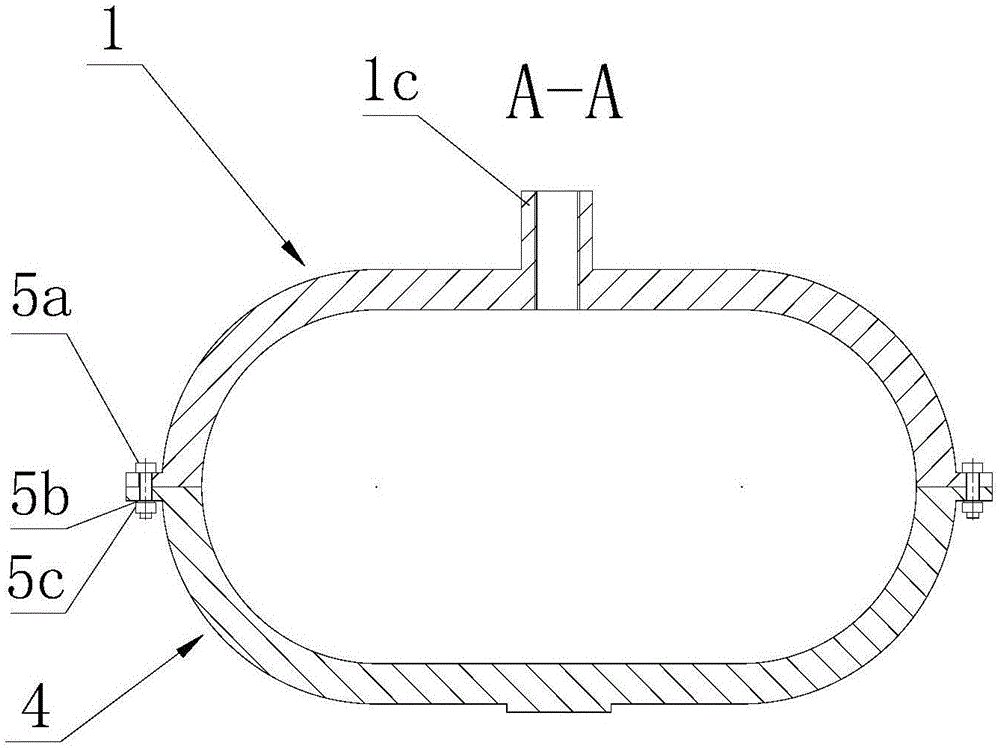

[0025] As shown in the figure, the present invention provides a kind of sealing joint that connects bamboo-shaped prestressed flat mouth plastic pipe with bolt and exhaust pipe, and described sealing joint 6 is made of the first half flat mouth pipe 1 and the second half The flat-mouth pipes 4 are butted and combined, and the butt joint surfaces are fastened and combined with a bolt fastener group 5 .

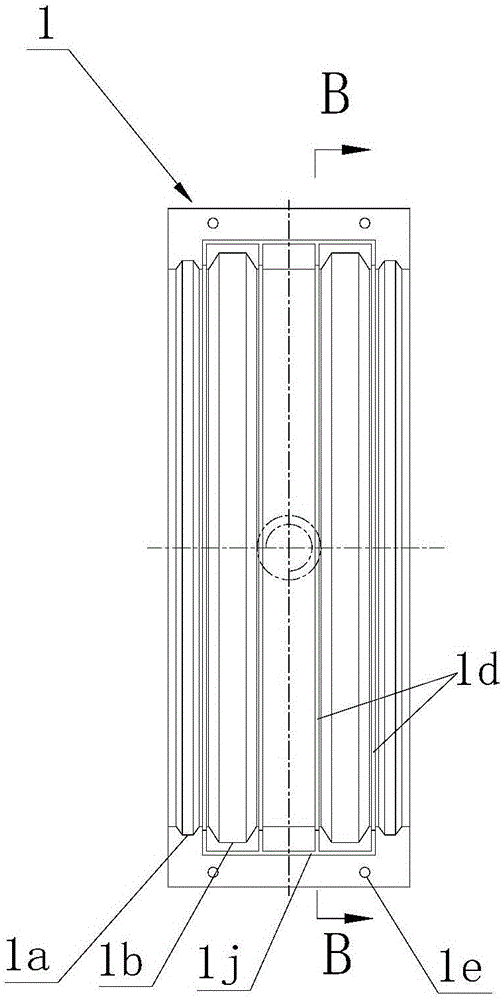

[0026] The outer edge of the first half of the flat pipe 1 protrudes and is provided with an exhaust pipe 1c that runs through the half of the flat pipe wall; the inner ring of the first half of the flat pipe 1 and the second half of the flat pipe On the inner ring of 4, there are first large groove 1b and second large groove 4b, first small groove 1a and second small groove 4a, first gasket groove 1d and The second gasket groove 4c.

[0027] The fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com