A kind of environment-friendly and toughened strong antibacterial degradable polylactic acid composite material and preparation method thereof

A technology of green environmental protection and composite materials, which is applied in the field of polymer composite materials, can solve the problems of limiting the application of polylactic acid composite materials, mechanical properties, processing performance and thermal properties, etc., to improve mechanical properties and thermal properties, improve mechanical properties, The effect of strong antibacterial properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

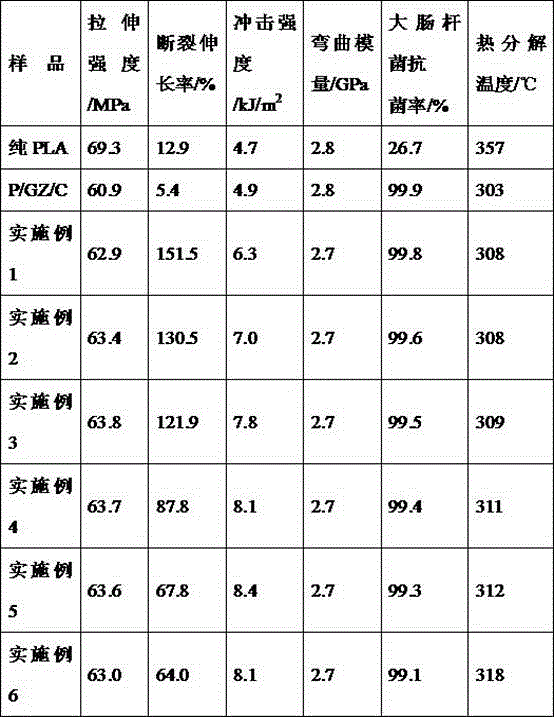

Examples

Embodiment 1

[0044] Step (1) Preparation of CCA: Weigh 3.33 parts of sodium chlorophyll cuprate into a round bottom flask filled with distilled water, stir mechanically for a certain period of time, add 0.56 parts of hydrochloric acid, continue stirring to precipitate the solution, and vacuum filter to obtain The CCA precipitate was washed repeatedly with distilled water until neutral, dried, weighed, and stored for future use.

[0045] Step (2) Surface treatment of nano-ZnO: Add 9 parts of nano-ZnO into a flask containing 30 ml of 95% ethanol aqueous solution, shake well, ultrasonically disperse at room temperature for 1.5 h, add 0.27 parts of KH550, and ultrasonically Vibrate for 1.5h, and stir on a magnetic stirrer for 1.5h, centrifuge, wash with ethanol, dry in a blast drying oven at 60°C, and set aside.

[0046] Step (3) Preparation of antibacterial masterbatch: Add the CCA obtained in step (1) and the modified nano-ZnO obtained in step (2) into a beaker containing 500ml of chloroform...

Embodiment 2

[0050] Step (1) Preparation of CCA: Weigh 3.89 parts of sodium chlorophyll cuprate into a round-bottomed flask filled with distilled water, stir mechanically for a certain period of time, add 0.65 parts of hydrochloric acid, and continue stirring to precipitate the solution. The CCA precipitate was obtained by vacuum filtration, washed repeatedly with distilled water until neutral, dried, weighed, and stored for future use.

[0051] Step (2) Surface treatment of nano-ZnO: Add 10.7 parts of nano-ZnO into a flask filled with 30 ml of 95% ethanol aqueous solution, shake well, ultrasonically disperse at room temperature for 1.5 h, add 0.32 parts of KH550, and ultrasonically Vibrate for 1.5 hours, and stir on a magnetic stirrer for 1.5 hours, centrifuge, wash with ethanol, dry in a blast drying oven at 60°C, and set aside.

[0052]Step (3) Preparation of antibacterial masterbatch: add the CCA obtained in step (1) and the modified nano-ZnO obtained in step (2) into a beaker containi...

Embodiment 3

[0056] Step (1) Preparation of CCA: Weigh 4.44 parts of sodium chlorophyll cuprate into a round-bottomed flask filled with distilled water, stir mechanically for a certain period of time, add 0.73 parts of hydrochloric acid, and continue stirring to precipitate the solution. The CCA precipitate was obtained by vacuum filtration, washed repeatedly with distilled water until neutral, dried, weighed, and stored for future use.

[0057] Step (2) Surface treatment of nano-ZnO: Add 12 parts of nano-ZnO into a flask containing 30 ml of 95% ethanol aqueous solution, shake well, ultrasonically disperse at room temperature for 1.5 h, add 0.36 parts of KH550, and ultrasonically Vibrate for 1.5h, and stir on a magnetic stirrer for 1.5h, centrifuge, wash with ethanol, dry in a blast drying oven at 60°C, and set aside.

[0058] Step (3) Preparation of antibacterial masterbatch: add the CCA obtained in step (1) and the modified nano-ZnO obtained in step (2) into a beaker containing 500ml of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com