High-accuracy intelligent electric control system of dry mix mortar production line

An electrical control system, dry-mixed mortar technology, applied in the directions of mixing operation control, control device, clay preparation device, etc., can solve the problems of numerous wiring, hardware loss, consumption of internal space of the electric control cabinet, etc., to avoid starting overcurrent tripping , save space, solve the effect of hardware vulnerable

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

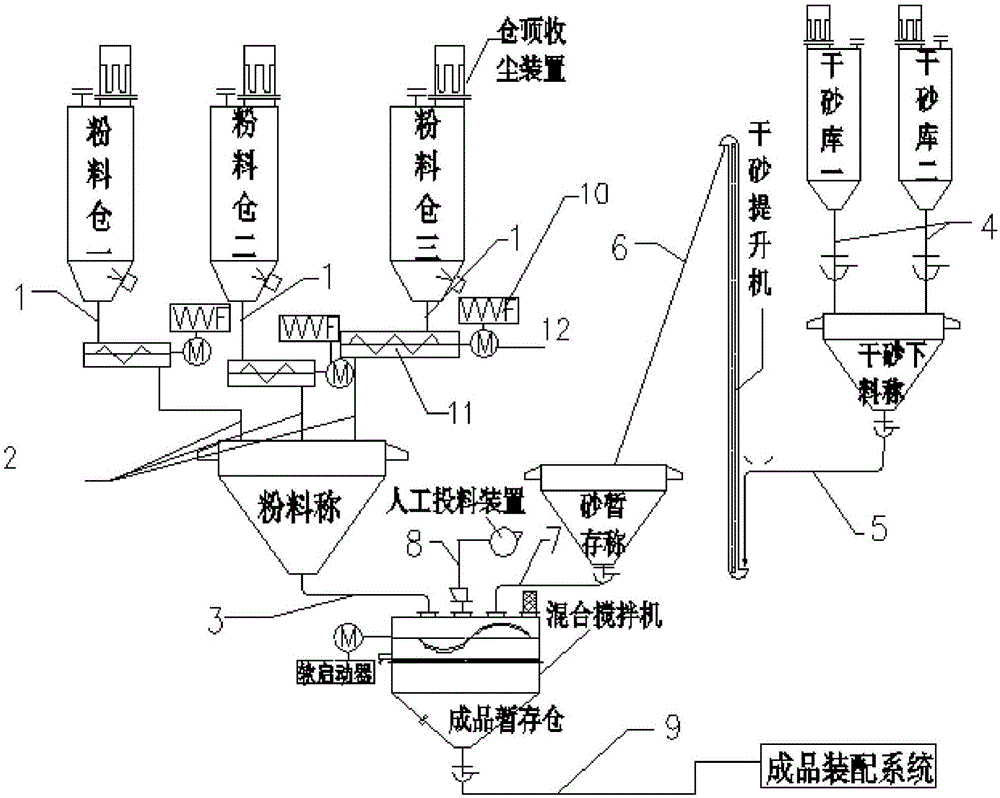

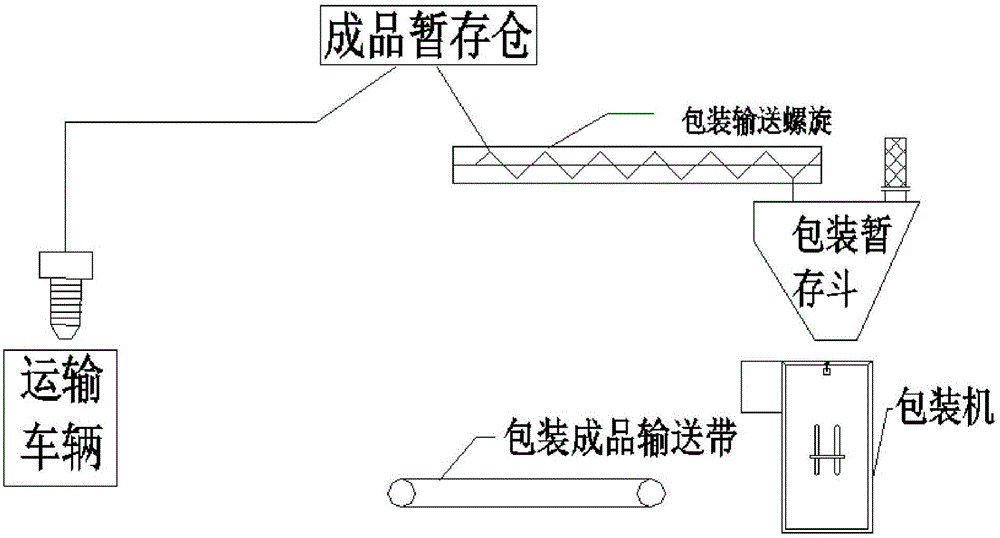

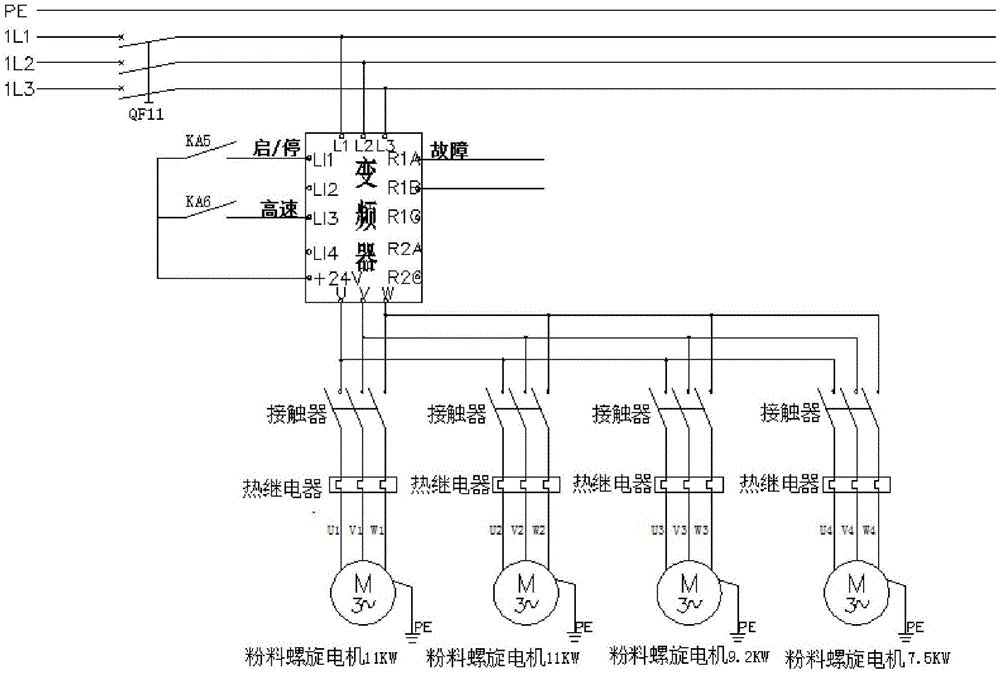

[0023] An intelligent electrical control system for a high-precision dry-mixed mortar production line, which is composed of a powder material distribution system, a sand material distribution system, a material weighing system, a mixing mixer, a manual feeding device, a dust collection system, and a finished product assembly system; the powder material The distribution system includes a powder silo and a powder screw 11; the sand distribution system includes a dry sand warehouse and a dry sand hoist; the material weighing system includes a powder scale, a dry sand discharge scale and a sand temporary storage scale; The dust collection system includes a dust collection device on the top of the powder silo and a bag dust collection device installed in the packaging system; the dust collection device on the top of the powder silo adopts a control method in which a motor protector is connected to a contactor; the finished product assembly The system includes a bulk feeding machine ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com