Buffering pad for relieving bidirectional expansibility of high-pressure gas bottle

A technology of high-pressure gas cylinders and cushioning pads, applied in the field of mechanical parts, to achieve the effect of small weight and space cost, and simple processing technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

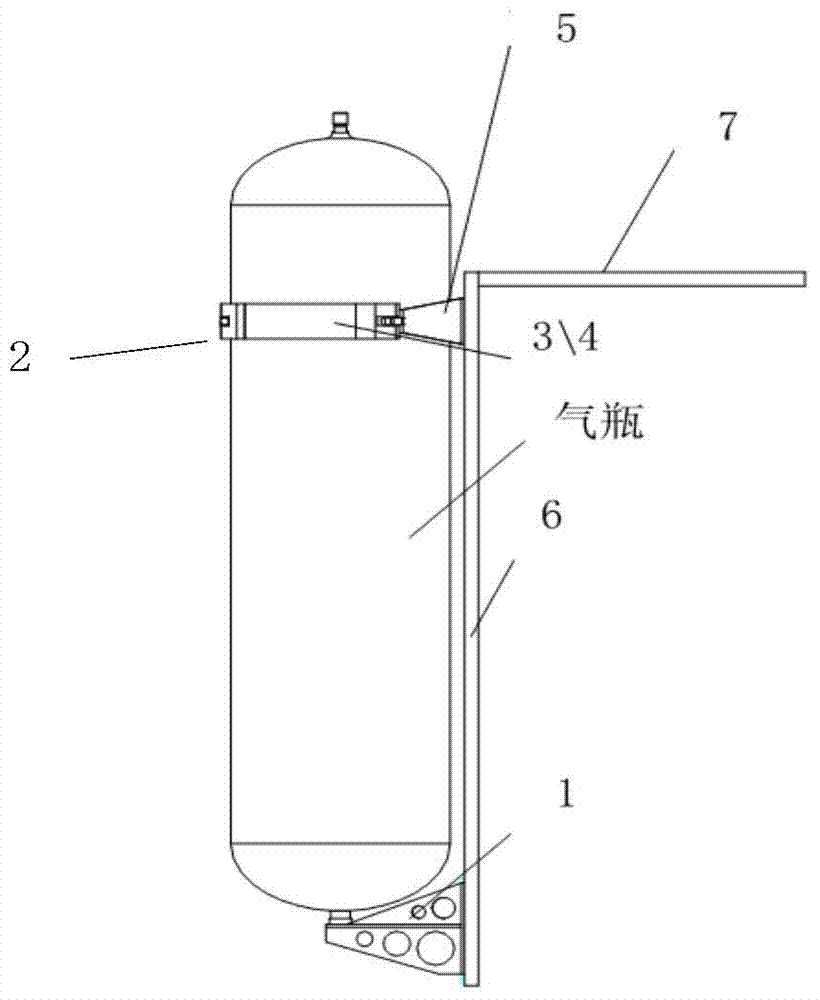

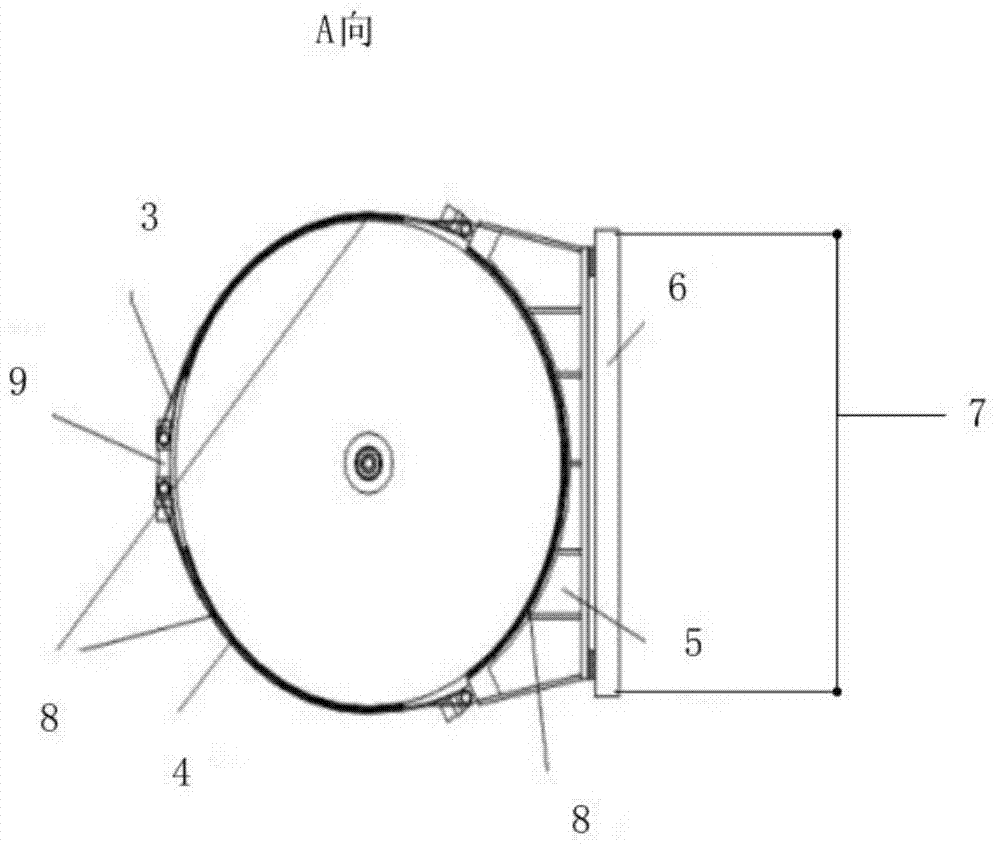

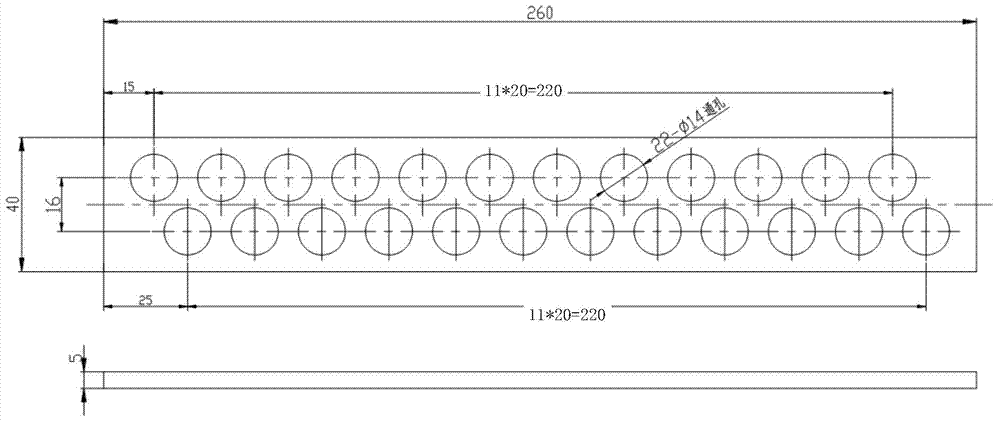

[0011] In this fastening system, the fastening of the cylindrical section of the gas cylinder is composed of two straps and a base installed on the main structure. The straps and the base are connected and compressed with bolts, and the two straps are connected with bolts. Control a certain tightening torque before. Cushion pads are placed between the strap and the gas cylinder, between the base and the gas cylinder, and the two pads in the two straps are exactly the same in shape, size, and material, and the other pad is placed in the base, with material, thickness, width, and round holes. The size is the same as the above two pieces, but the total length and the number of internal circular holes are different. The processing method of the buffer pad is to use the 5mm thick rubber pad raw material to cut directly into a rectangle, and then use the mold to position and process the round hole on this basis. The processing process is simple and easy.

[0012] figure 1 and fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com