Reinforcement cage manufacturing apparatus and method

A technology for manufacturing equipment and steel cages, applied in the field of steel cage manufacturing equipment, can solve the problems of large floor area, poor tightness of steel cages, high equipment costs, etc., and achieve smooth operation, high coaxiality and good effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

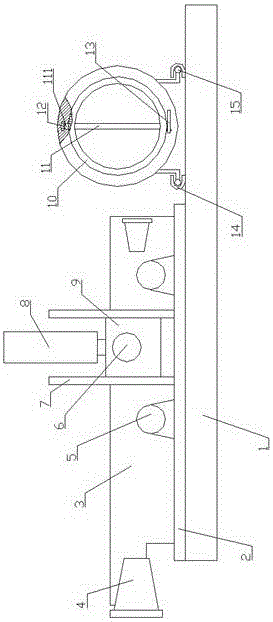

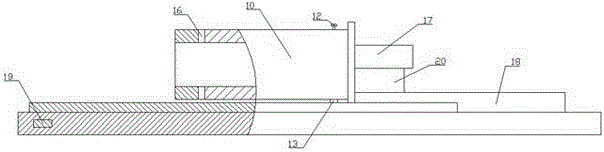

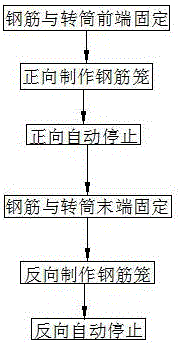

[0025] Such as figure 1 and figure 2 The shown steel cage manufacturing equipment includes the frame 1 and the power transmission motor and power supply that provide power for the operation of the equipment; Provides power for the operation of the components.

[0026] The frame 1 is provided with a pay-off mechanism and a drum 10 located at the side of the pay-off mechanism. In this embodiment, the pay-off mechanism and the rotating drum 10 are arranged in cooperation, and the height difference between the pay-off mechanism and the rotating drum 10 needs to ensure that when the wire-releasing mechanism transfers the steel bars to the rotating drum 10, there is no need to correct Any bending or other treatment of the steel bar can just make the steel bar wrap around the lower surface of the rotating drum 10 .

[0027] In order to adjust the positional relationship between the pay-off mechanism and the drum 10 and improve the application range of the device, an adjustment pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com