Non-contact slurry passing device used in continuous ball mill

A non-contact, continuous ball milling technology, applied in grain processing and other directions, can solve problems such as waste of raw materials, poor rotation speed, and pollution on site.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with specific embodiment:

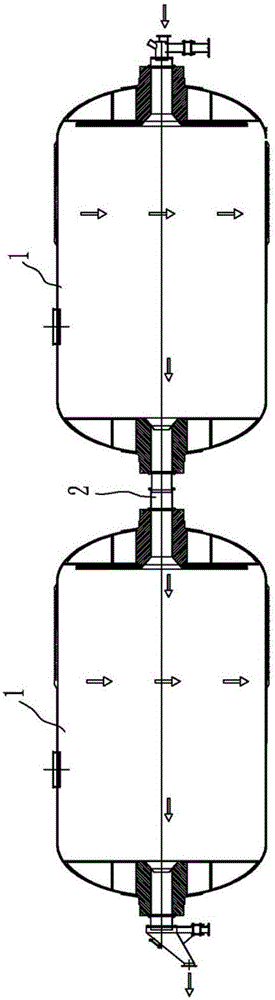

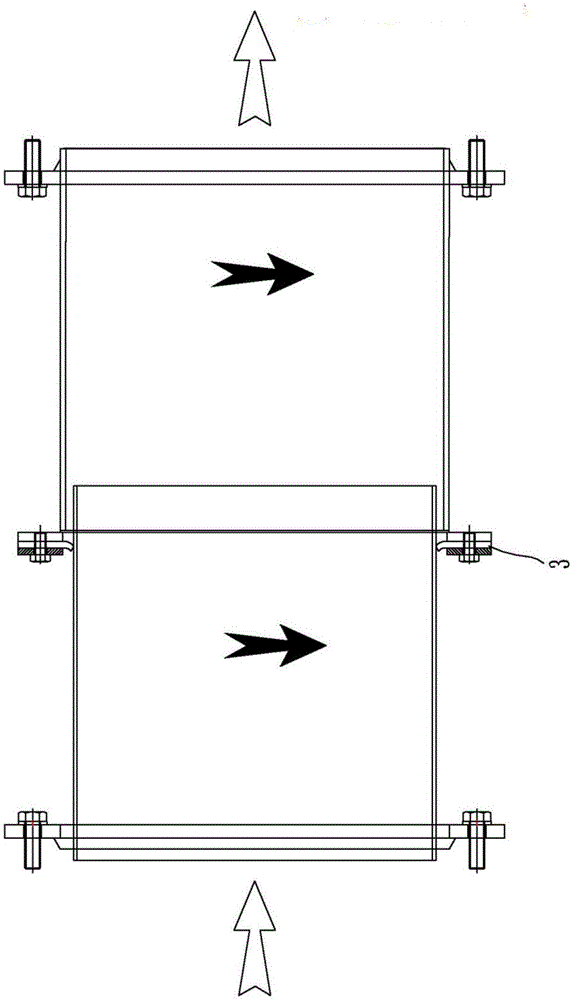

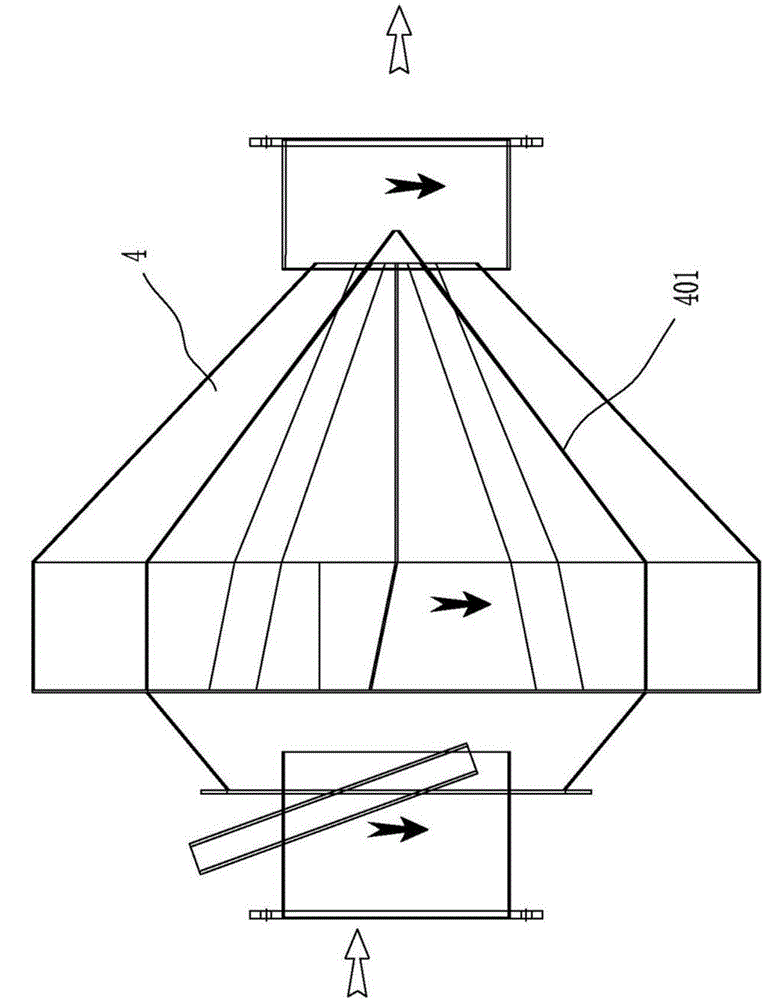

[0014] See attached Figures 3 to 4 As shown, a non-contact pulping device used between continuous ball mills described in this embodiment includes a plurality of ball mill cylinders 1 arranged adjacently, and a plurality of ball mill cylinders 1 arranged between adjacent ball mill cylinders 1 A non-contact pulping device, the non-contact pulping device includes a slurry outlet pipe 5 and a tapered scoop that are fastened respectively at the outlet and inlet of the adjacent pair of ball mill cylinders 1 Slurry cone 4, wherein the above-mentioned slurry outlet pipe 5 is nested in the scooping cone 4, and at the same time, the inner cavity of the scooping cone 4 is also equipped with a plurality of spirals for quickly scooping out the mud. Chute 401.

[0015] At the same time, in order to ensure that the above-mentioned continuous ball mill in this plan can quickly carry out...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com