A new technology of LED packaging

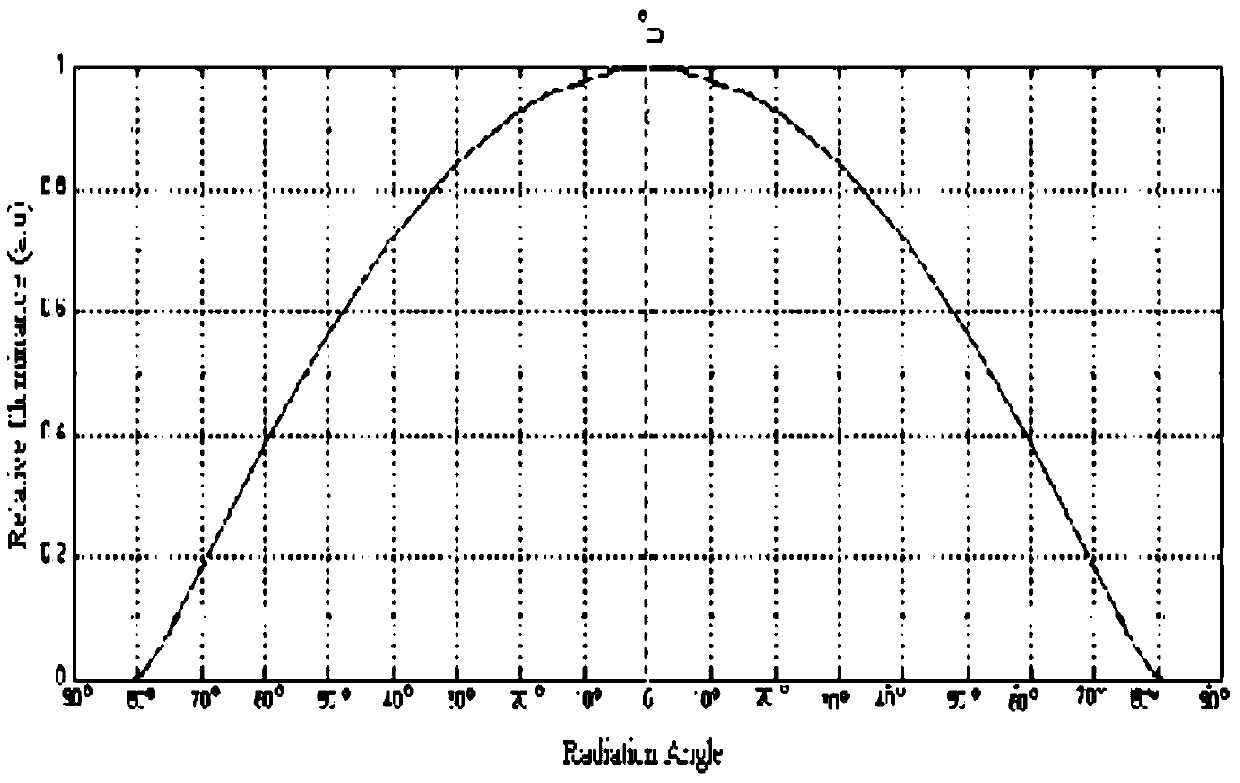

A technology of LED packaging and LED lamp beads, which is applied in the direction of semiconductor devices, electrical components, circuits, etc., can solve the problems of difficulty in improving the lamp bead light effect, poor sealing, and poor thermal conductivity, so as to improve the effect of heat conduction, improve the distribution, The effect of reducing the thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

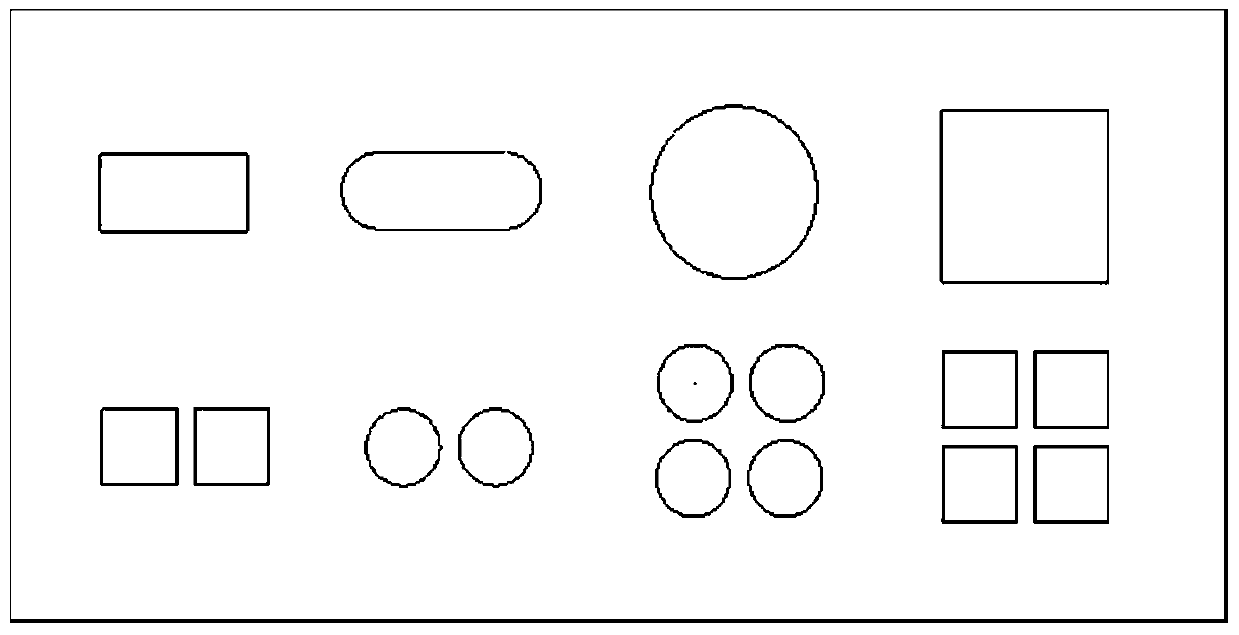

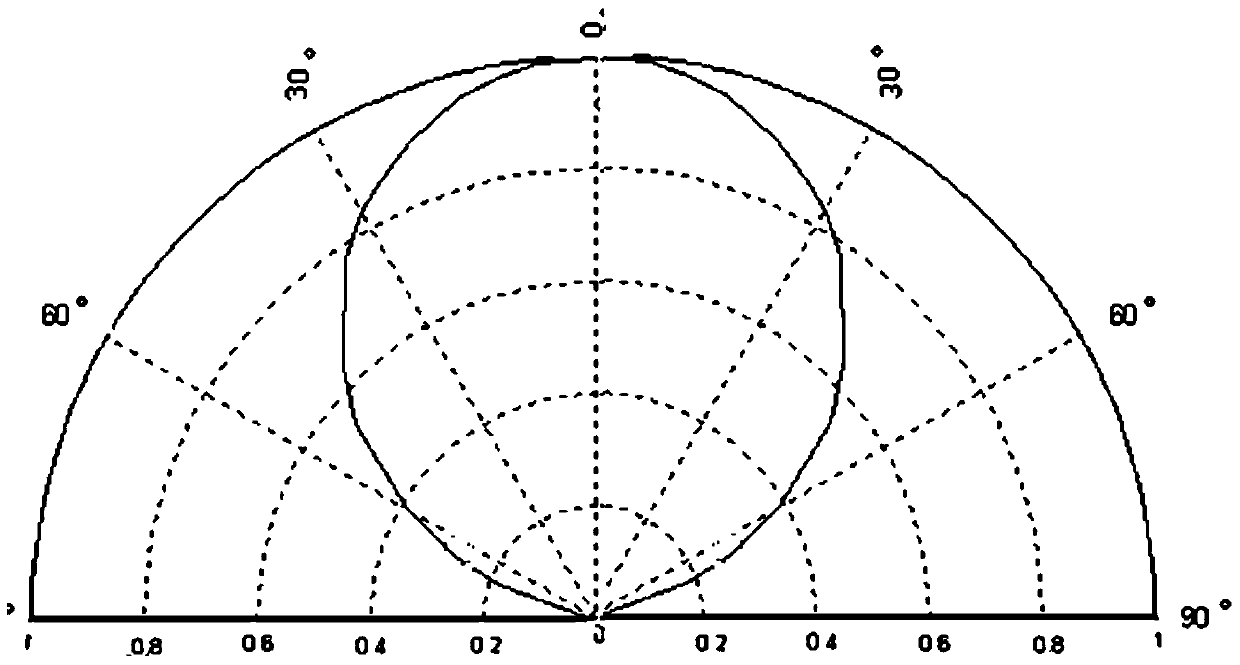

Image

Examples

Embodiment Construction

[0042] A new LED packaging process, comprising the following steps:

[0043] Chip detection: Check whether the surface of the PLCC5050 LED lamp bead chip with a production power > 3W has mechanical damage and pitting, and whether the size of the LED lamp bead and the electrode size meet the process requirements;

[0044] Expansion: Use a expansion machine to expand the film bonded to the LED lamp bead chips. Since the LED lamp bead chips are still arranged closely after dicing and the spacing is small (about 0.1mm), it is not conducive to the operation of the subsequent process. We use a sheet expander to expand the film bonding the chip, so that the distance between the LED lamp bead chips is stretched to about 0.6mm;

[0045] Glue dispensing: Apply silver glue or insulating glue on the corresponding position of the LED bracket (for GaAs and SiC conductive substrates, red, yellow, and yellow-green chips with back electrodes use silver glue, for blue light on sapphire insulati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com