Programming algorithm for conical large-angle automatic fiber placement

An automatic yarn laying and large-angle technology, which is applied in the direction of calculation, special data processing applications, instruments, etc., can solve the problems of increasing and decreasing yarns, achieve the effect of simple programming method and improved laying efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

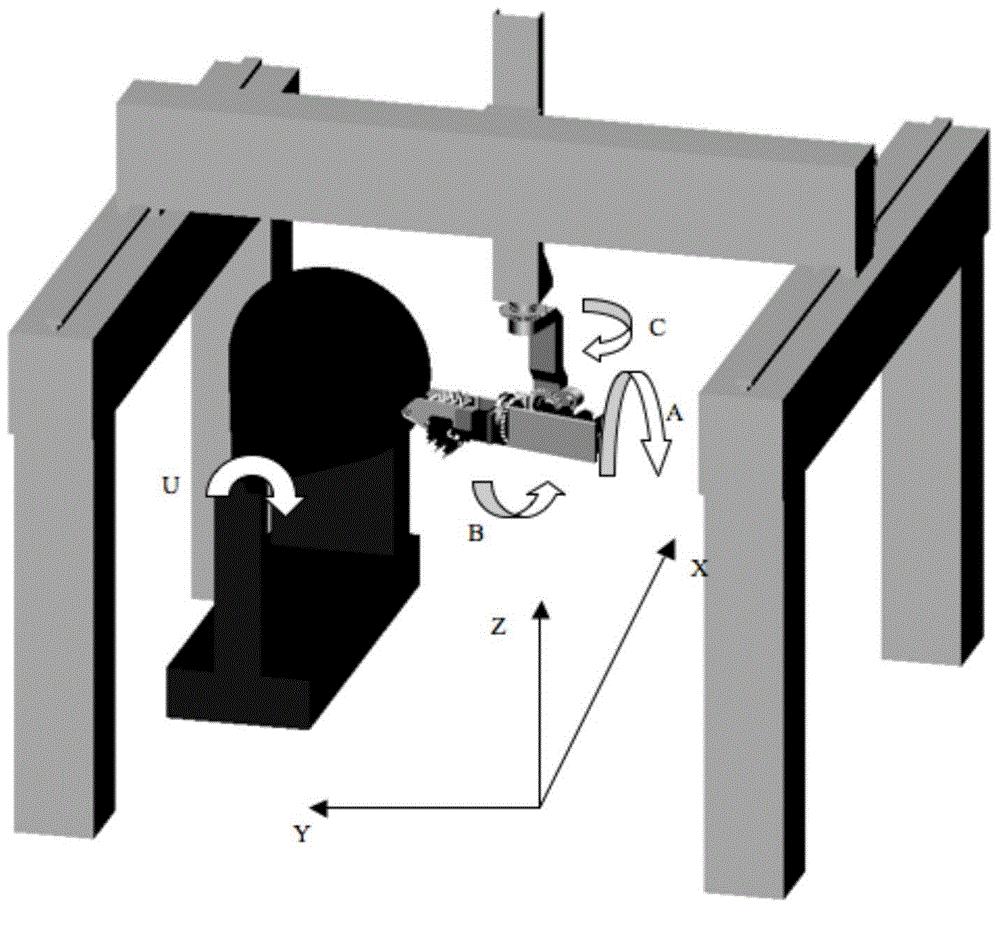

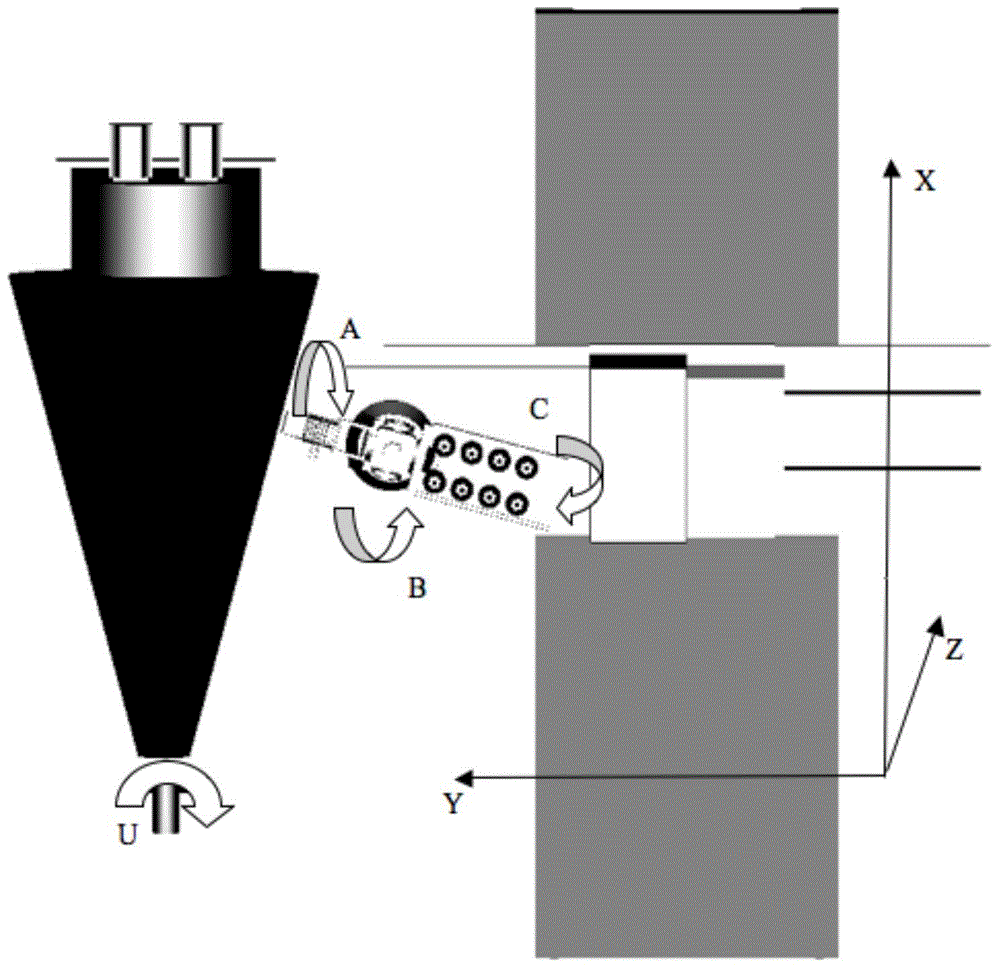

[0034] like figure 2 Shown is a gantry-type 7-axis linkage CNC laying equipment and a conical mold.

[0035] (1) Turn the B axis to the horizontal position, adjust the lifting axis Z, so that the axis of the B axis and the main shaft of the mold are in the same horizontal plane; at the same time, adjust the rotation axis C according to the semi-cone angle of the cone, so that the pressure roller is perpendicular to the horizontal generatrix of the cone; adjust the level The moving axes X and Y make the pressure roller align with the contour line of the large end surface of the cone.

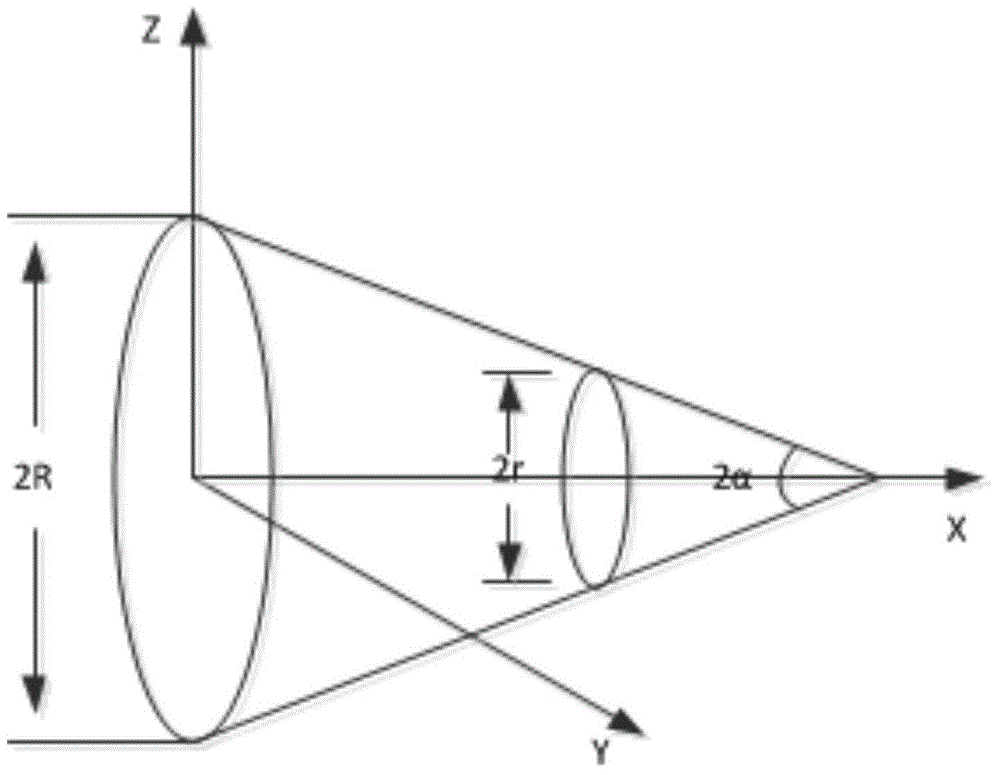

[0036] (2) According to the relationship between the conical helix angle and the pitch, calculate the helix angle of the pressure roller at the large end face of the cone shell And adjust the A-axis to this angle, where α is the semi-cone angle of the cone, and R is the radius of the large end section of the cone.

[0037] (3) Set the length x of each step of the X-axis (x

[0038] (4) Calcu...

Embodiment 2

[0041] like figure 2 Shown is composed of gantry-type 7-axis linkage CNC laying equipment and conical molds.

[0042] (1) Turn the B-axis to the horizontal position, adjust the lifting axis Z, so that the axis of the B-axis is in the same horizontal plane as the main shaft of the mold; at the same time, adjust the C-axis according to the semi-cone angle of the cone, so that the pressure roller is perpendicular to the horizontal generatrix of the cone; adjust the translation Axis X and Y, so that the pressure roller is aligned with the contour line of the small end face of the cone.

[0043] (2) According to the relationship between the conical helix angle and the pitch, calculate the helix angle of the pressure roller at the small end face of the cone shell And adjust the A-axis to this angle, where α is the semi-cone angle of the cone, and r is the radius of the small end section of the cone.

[0044] (3) Set the length x of each step of the X-axis (x>0), and calculate th...

Embodiment 3

[0048] like figure 2Shown is a gantry-type 7-axis linkage CNC laying equipment and a conical mold. First, turn the B-axis to the horizontal position, adjust the lifting axis Z, so that the axis of the B-axis is in the same horizontal plane as the main axis of the mold; at the same time, adjust the C-axis according to the semi-cone angle of the cone, so that the pressure roller is perpendicular to the horizontal generatrix of the cone; adjust the translation axis X and Y, so that the pressure roller is aligned with the contour line of the conical end surface. Secondly, according to the relationship between the cone helix angle and the pitch, calculate the helix angle of the pressure roller at the end face of the cone shell, and adjust the A axis to this angle. Finally, set the length x of each step of the X-axis, and calculate the length x tanα of each step of the Y-axis, and the rotation angle of the spindle and the amount of rotation of the A axis Output the relative va...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com