Bilateral frost-heaving test device for porous materials and testing method

A technique for porous materials and frost heaving tests, applied in measuring devices, analytical materials, thermal analysis of materials, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

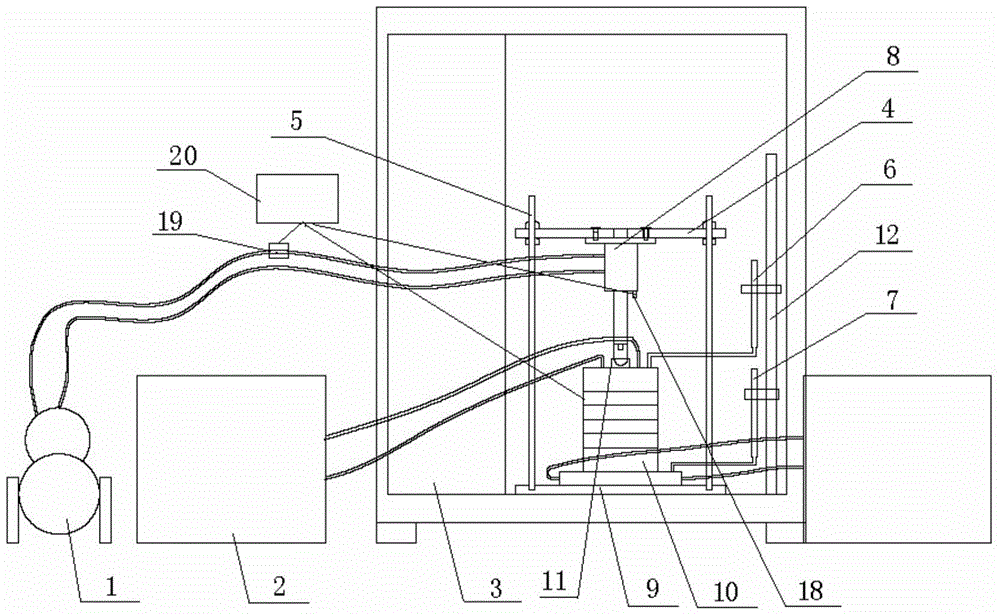

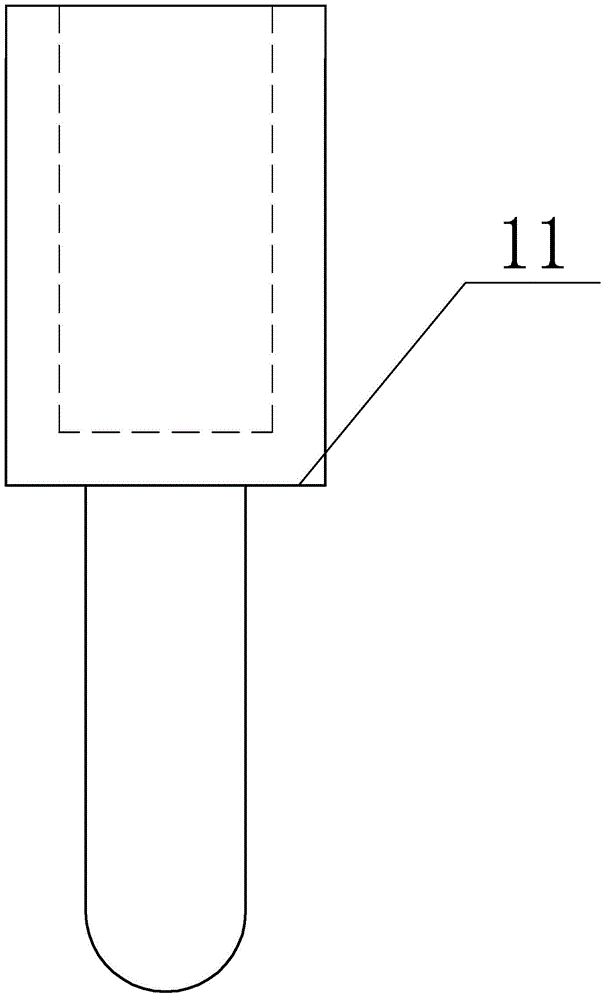

[0021] Specific implementation mode one: combine Figure 1-Figure 9 Description of this embodiment, a bilateral frost heaving test device and test method for porous materials, which includes a press 1, a constant temperature and humidity curing box 3, a reaction force frame top plate 4, a reaction force frame support 5, a first storage Water test tube 6, the second water storage test tube 7, cylinder 8, base 9, frost heaving test piece package assembly 10, pressure head 11, test tube rack 12, LVDT displacement sensor 18, pressure sensor 19, data collector 20 and two cooling The bath circulator 2; the LVDT displacement sensor 18 is installed on the cylinder body of the cylinder 8 close to the piston rod, the top plate 4 of the reaction force frame is fixedly installed on the top of the frame support 5, and the base 9 is fixedly installed on the bottom end of the reaction force frame support 5. The expansion test piece set assembly 10 is fixedly installed on the base 9, the cyli...

specific Embodiment approach 2

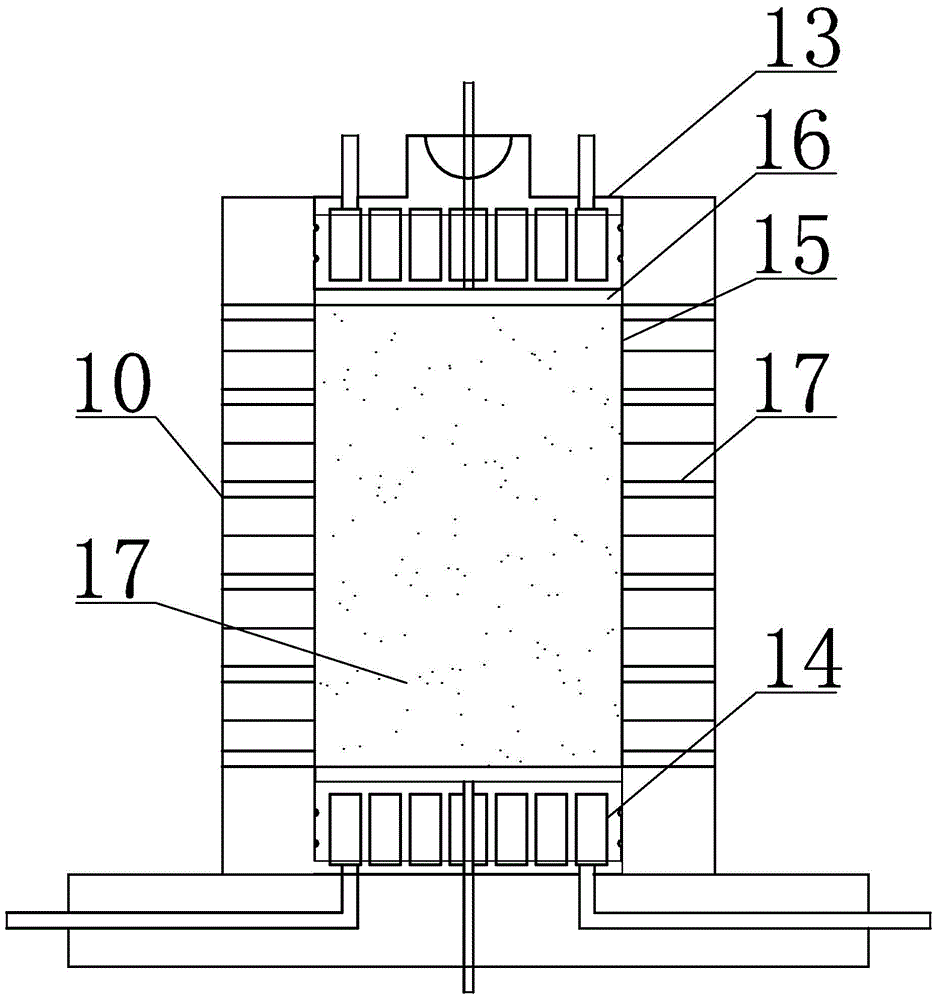

[0022] Specific implementation mode two: combination Figure 1-Figure 9 Describe this embodiment, a bilateral frost heave test device and test method for porous materials, the frost heave test piece package assembly 10 includes a first temperature control plate 13, a second temperature control plate 14, a leather sheath 15, two A permeable stone 16, a plurality of temperature sensors and a plurality of heat insulating rings 17; the leather sheath 15 is a cylindrical leather sheath, and a plurality of heat insulating rings 17 are arranged vertically from top to bottom to form a circular sleeve; the second temperature control plate 14, The two permeable stones 16 and the first temperature control plate 13 are sequentially arranged in the circular sleeve from bottom to top, the porous material to be tested is arranged between the two permeable stones 16, and a plurality of temperature sensors are installed on the porous material to be tested. The top of the holster 15 is set on t...

specific Embodiment approach 3

[0023] Specific implementation mode three: combination figure 1 , figure 2 , Figure 4 and Figure 5 Describe this embodiment, a double-sided frost heaving test device and test method for porous materials, the first temperature control plate 13 is a circular plate, and the inside of the circular plate is processed with a first serpentine sealing groove along the radial direction 13-1, the top of the circular plate is processed with the first water bath circulation fluid inlet, the first water bath circulation outlet and the first water supply pipe hole, the first water bath circulation fluid inlet and the first water bath circulation outlet are connected with the first serpentine seal groove 13-1 is connected, the outlet pipe of the first water storage test tube 6 passes through the first water replenishment pipe hole and is arranged at the permeable stone 16 located above, and the first water bath circulation fluid inlet and the first water bath circulation outlet pass thr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com