Medium-deep hole room pillar mining method for limestone underground mine mining

A limestone and mining method technology, applied in the field of medium-deep hole room-and-pillar mining method, can solve the problems of rock falling property, poor ventilation conditions, low production capacity, etc., achieve high labor production efficiency, shorten mining time, and accurate mining work. small amount of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

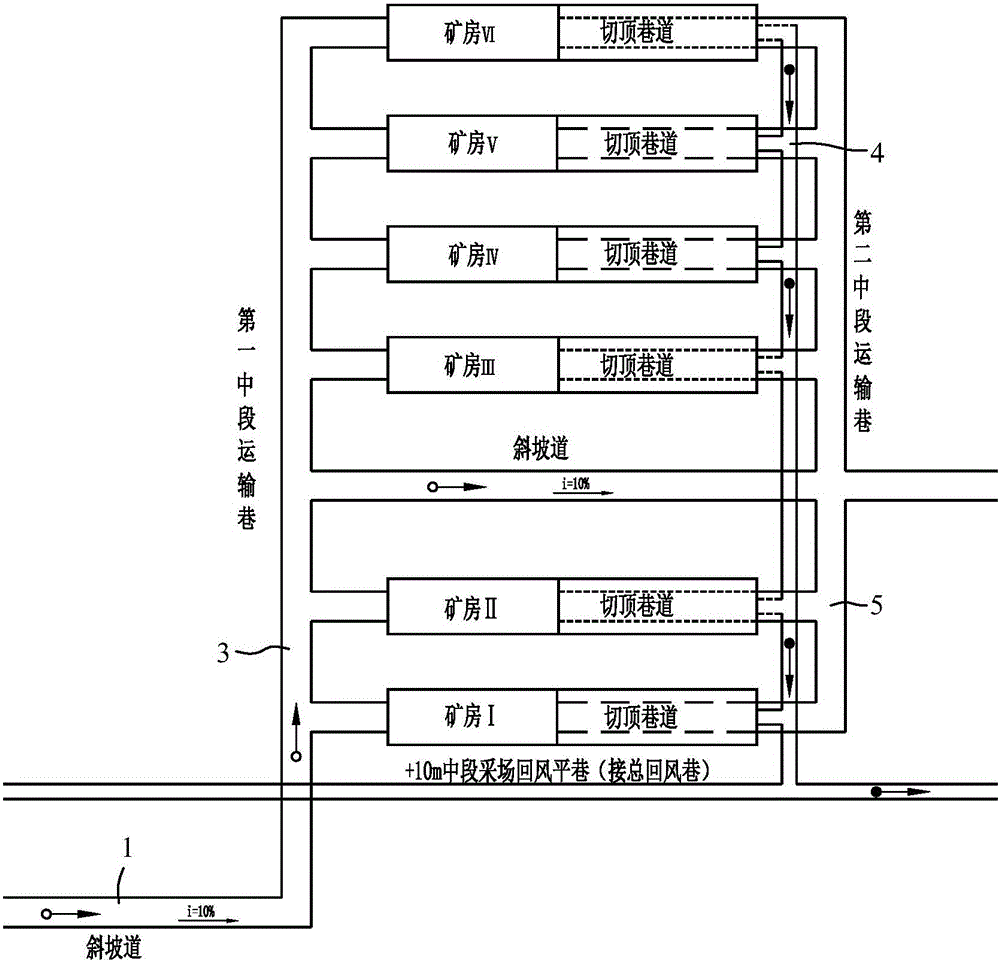

[0023] A certain limestone underground mine has adopted the technical scheme of the present invention. The mine was previously mined by the shallow-hole room-and-pillar method, which has always had the disadvantages of high labor intensity, low production efficiency, and poor ventilation conditions. Problem, to achieve the effect of safe and efficient mining of the limestone underground mine, the specific implementation is as follows:

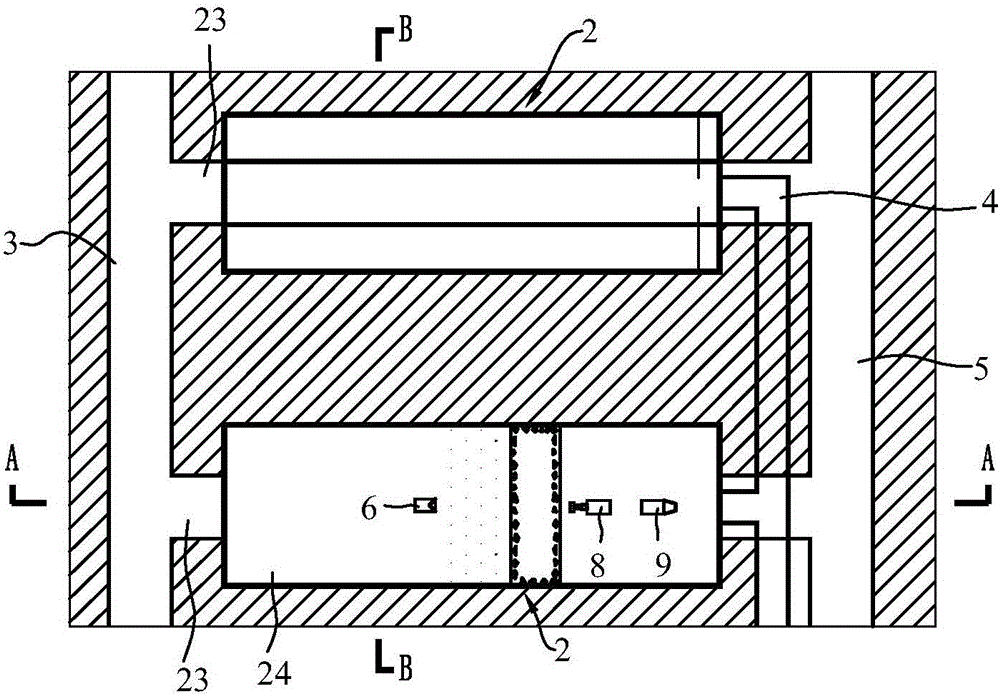

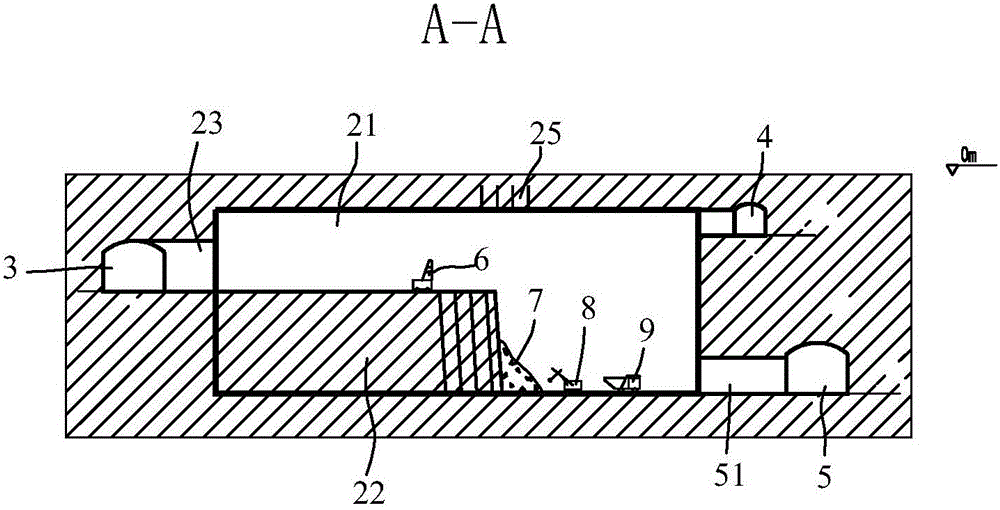

[0024] refer to Figure 1 to Figure 5 , which shows the specific structure of the preferred embodiment of the present invention, but the actual application direction of the present invention is not limited thereto.

[0025] The invention provides a medium and deep hole room and pillar mining method for underground mining of limestone, comprising the following steps:

[0026] S10. The ramp 1 is developed. In the limestone underground mine, the ramp 1 is driven to the vicinity of the mine room 2 to be mined, with a slope of 10%, and the first m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com