Shear pin type bypass valve

A shear pin and bypass valve technology, applied in wellbore/well valve devices, wellbore/well components, earth-moving drilling, etc., can solve the problems of high cost per unit, many sealing parts, complicated debugging experiments, etc. To achieve the effect of convenient entry and exit, avoiding the effect of suction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

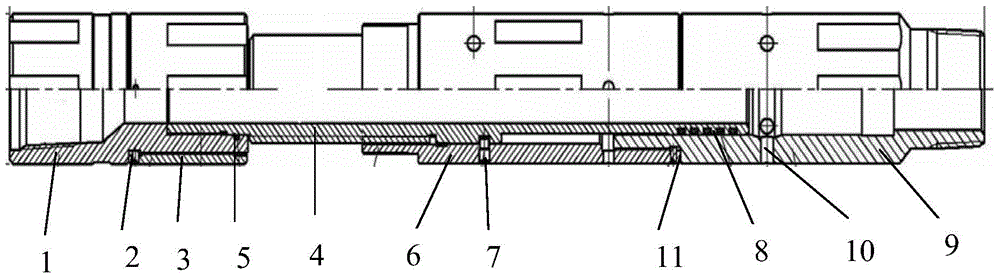

[0014] like figure 1 As shown, the shear pin bypass valve of the present invention includes an upper joint 1, a splined mandrel 4, and a lower joint 9. The upper end of the splined mandrel 4 is sleeved with an upper joint 1 through a screw connection, and the splined The lower end of the mandrel 4 is covered with a lower joint 9 that can move up and down along the outer wall of the spline mandrel 4, and an "O" ring 8 is provided on the outer wall of the spline mandrel 4 in contact with the lower joint 9; 4. There is a spline mandrel outer cylinder 6 set on the spline mandrel 4 on the outer side. The upper end of the spline mandrel outer cylinder 6 has a certain distance from the bottom end of the upper joint 1. The lower end of the spline mandrel outer cylinder 6 Screw it on the outside of the lower joint 9 through a screw, and fix it with the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com