A scientific investigation ship with a wire rope anti-rust maintenance device

A technology for steel wire ropes and research ships, applied in the field of scientific research ships, can solve the problems of small deck area, high labor intensity, unsafety, etc., and achieve the effects of small size, high degree of automation, and safe and convenient use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

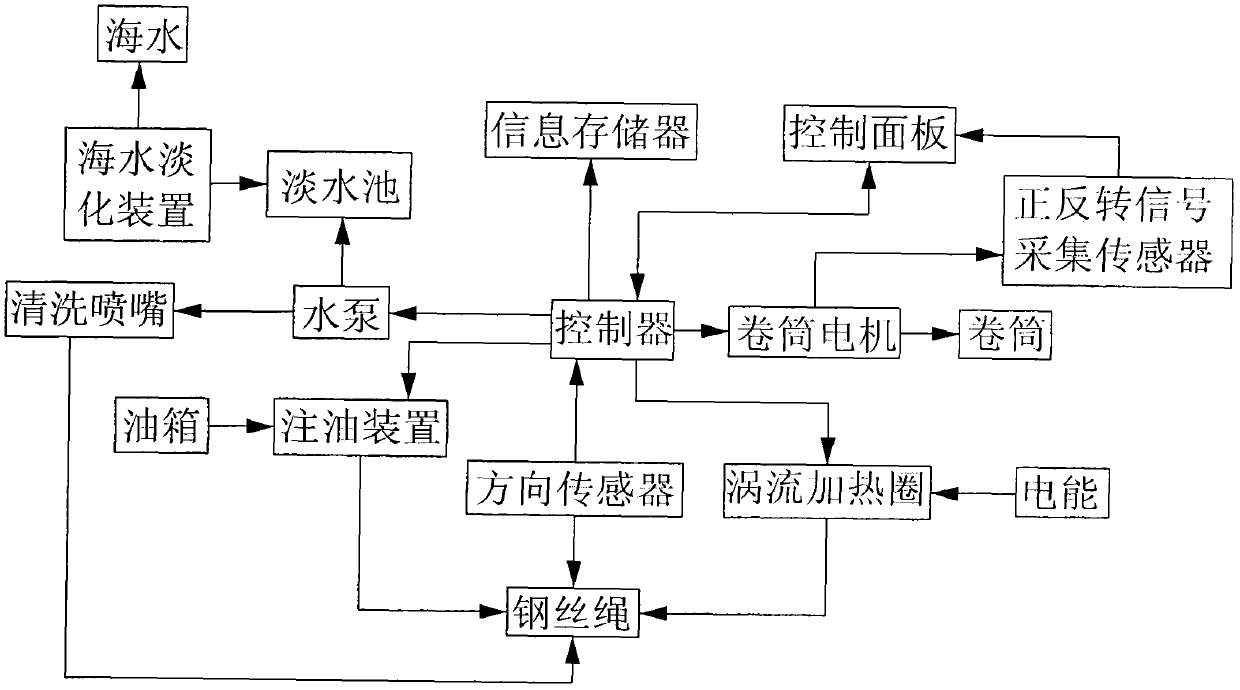

[0023] Such as figure 1 , 3 As shown, a scientific investigation ship with a steel wire rope antirust maintenance device includes a hull 16 on which a steel wire rope antirust maintenance device 17 is provided. The steel wire rope antirust maintenance device 17 includes a steel wire rope that is stained with seawater 1 a cleaning device 2 for cleaning, a drying device 3 for drying the cleaned steel wire rope 1, a winding device 4 for driving the steel wire rope 1 to expand and contract, and a controller, in which the cleaning device 2, Either side of the drying device 3 or the winding device 4 is provided with a direction sensor for detecting the extension or retraction of the steel wire rope 1. The direction sensor detects that the steel wire rope 1 is retracted inwardly and sends a detection signal to the controller. The controller After receiving the detection signal, send a start signal for driving the cleaning device 2 and drying device 3 to maintain the steel wire rope 1 ...

Embodiment 2

[0036] The same part of this embodiment and Embodiment 1 will not be described again, the difference is that: another way of adding the anti-rust liquid is to include a storage chamber 13 containing the anti-rust liquid 12. The antirust liquid 12 in the cavity 13 is provided with an oil splashing flywheel 15 which splashes the antirust liquid 12 onto the steel wire rope 14 . In the detection of the wire rope stretching and retracting signal, another method of this embodiment is: the winding device 4 is provided with a signal sensor connected to the controller signal for detecting the forward and reverse of the winding device 4, said The signal sensor is electrically connected with the control panel. The winding device 4 is generally driven by a geared motor or an ordinary motor supplemented by a reducer to rotate the reel of the wire rope. , can also be used to spray or be provided with a nozzle for spraying oil, or be provided with a dipping tank for impregnating the steel w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com