Pneumatic tuck-in device for loom

A tuck-in device and loom technology, applied in looms, textiles, textiles and papermaking, etc., can solve the difficulty of adjusting and controlling the tuck-in width, difficult to fine-tune the flying attitude of the yarn, and reduce the dyeing of finished fabrics. It can improve the efficiency of adjustment work, reduce the risk of airway blockage, and improve the dye permeability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to better understand the present invention, the implementation manner of the present invention will be explained in detail below in conjunction with the accompanying drawings.

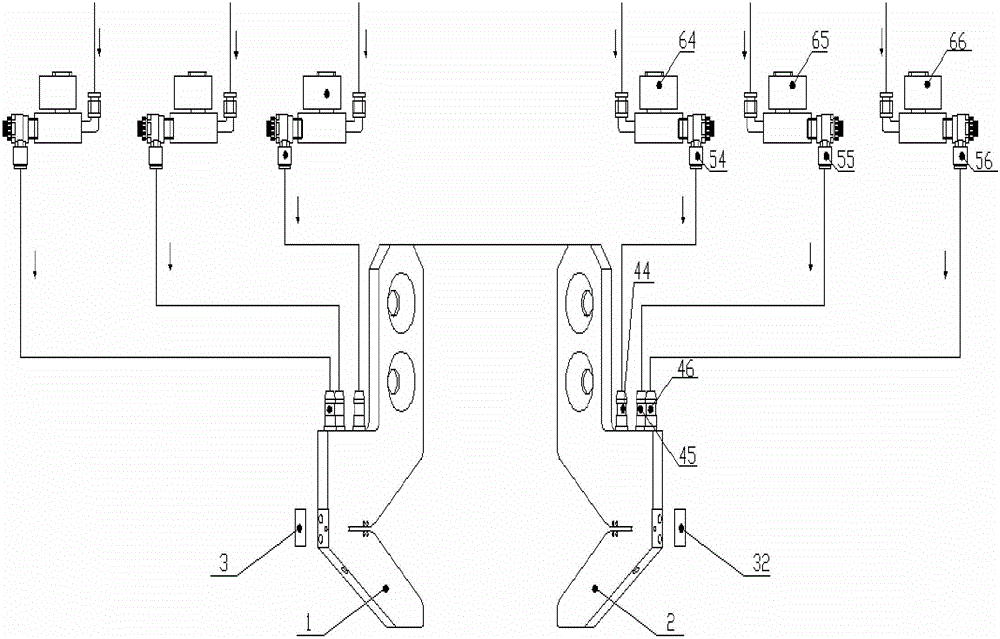

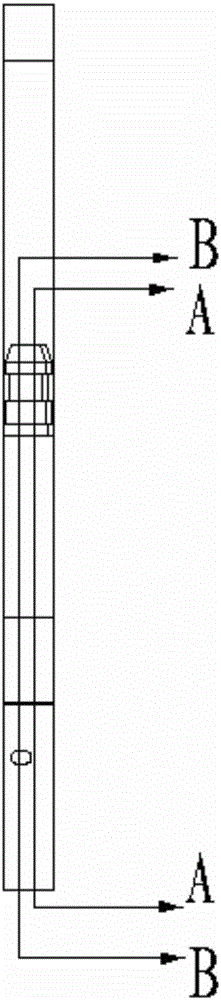

[0026] Such as Figure 1 to Figure 8 As shown, a pneumatic folding device for a loom includes a left folding block 1 and a right folding block 2, and cover plates 3, 32 and copper joints 44, 45 are respectively provided on the left folding block 1 and the right folding block 2. , 46, shut-off valves 54, 55, 56, solenoid valves 64, 65, 66, the left folding block 1 and the right folding block 2 are symmetrical structures, wherein the left folding block 1 is installed on the left side of the cloth, and the right folding block 2 installed on the right side of the cloth. The structure will be described in detail below with respect to the structure of the fold-in block 2 on the right side.

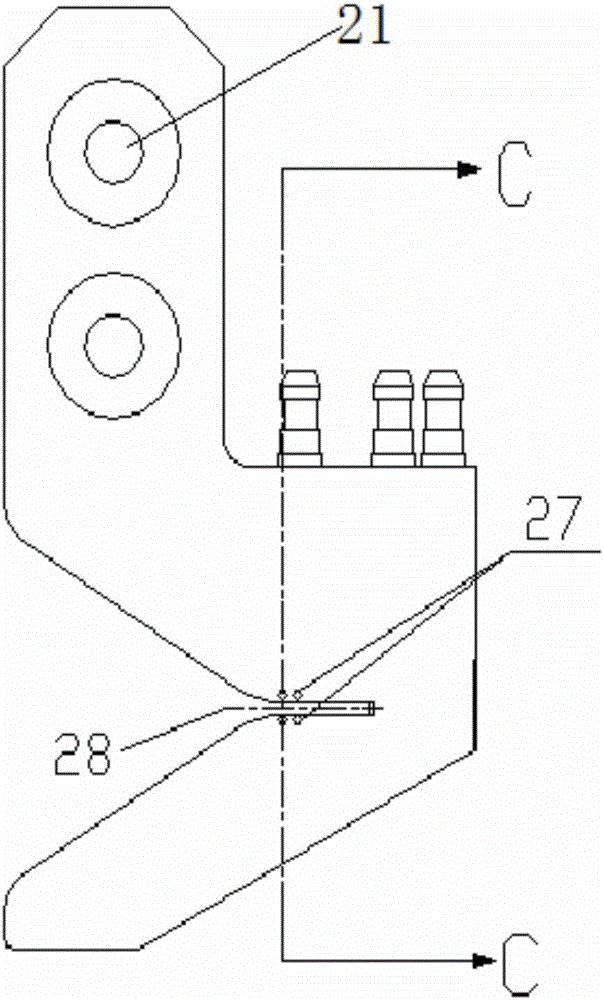

[0027] Such as Figure 1-Figure 5 As shown, two installation holes 21 are provided on the upper par...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com