Large-section cast ferrite nodular cast iron and preparation method thereof

A ductile iron and ferrite technology, which is applied in the field of large-section as-cast ferritic ductile iron QT580-15A and its preparation, can solve problems such as great influence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

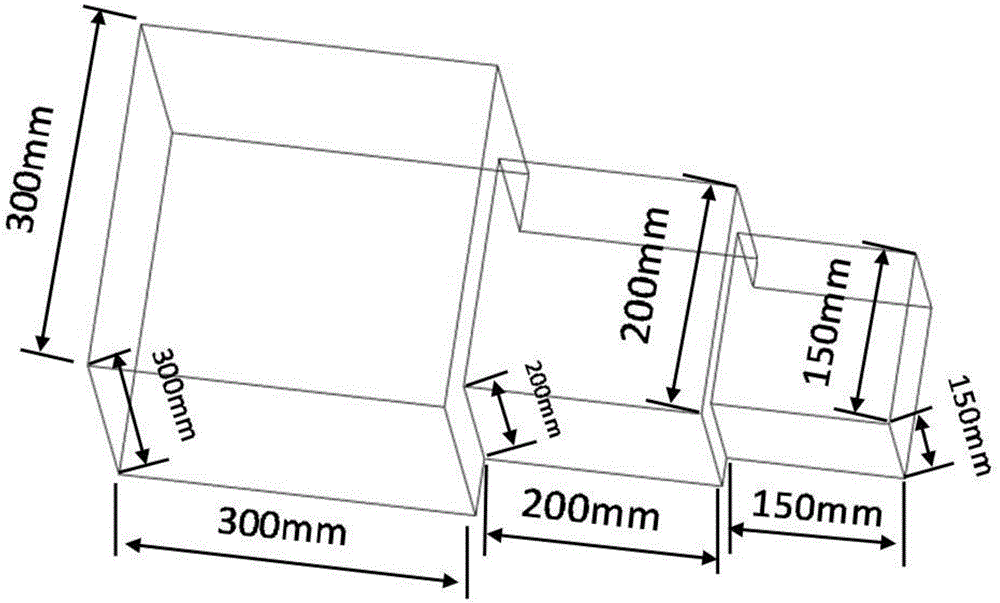

[0034] Example 1: Preparation of a stepped ingot of 300mm×300mm×300mm+200mm×200mm×200mm+150mm×150mm×150mm. For the structure and size of the stepped ingot, see figure 1 .

[0035]According to the method of the invention, the element composition of the ductile iron material: C: 3.1-3.5wt%, Si: 3.0-4.0wt%, Mn≤0.3wt%, P≤0.04wt%, S: 0.01-0.03wt%, Sb : 0.001-0.006wt%, Mg: 0.03-0.05wt%, Re: 0.01-0.03wt%, and the rest is iron and impurities produced during the preparation process.

[0036] The ductile iron material of the above formula (pig iron: 40-60wt%, steel scrap: 10-30wt%, recycle material: 20-40wt%) is first smelted, and the temperature of the molten iron is controlled to be 1430-1460°C. Carry out spheroidizing treatment, the formula of spheroidizing agent is Mg 5-7wt%, Si 40-50wt%, Re 0.5-1.0wt% and the rest is iron, the addition of nodulizing agent is 1.0~1.2wt% of total molten iron, A covering agent is added on the nodulizer, the covering agent is a low-silicon, high-iron...

Embodiment 2

[0040] Embodiment 2: the preparation made with the square ingot of 400mm * 400mm * 400mm

[0041] According to the method of the invention, the element composition of the ductile iron material: C: 3.1-3.5wt%, Si: 3.0-3.8wt%, Mn≤0.3wt%, P≤0.04wt%, S: 0.01-0.03wt%, Sb : 0.001-0.006wt%, Mg: 0.03-0.05wt%, Re: 0.01-0.03wt%, and the rest is iron and impurities produced during the preparation process.

[0042] The nodular cast iron material of the above formula is first smelted, and the temperature of the molten iron is controlled to be 1420-1450° C. for spheroidizing treatment, and the rest is the same as in Example 1.

[0043] The production shows that the performances of the 400mm×400mm×400mm square ingot prepared by the method of this embodiment are as follows: tensile strength 586MPa, 545MPa, yield strength 459MPa, 440MPa , Elongation 19%, 16%, the organization of the material is a pure ferrite matrix organization.

Embodiment 3

[0045] Preparation of high-strength and high-toughness ferritic nodular cast iron with large cross-section (wall thickness greater than 60 mm). The 2.5MW wind power bearing end cover casting is selected for trial production. The bearing end cover has a single weight of 0.8 tons and a main wall thickness of 100-220mm. Follow the steps below:

[0046] Select pig iron: 50wt%, steel scrap: 20wt%, recycle material: 30wt%; first smelt, pig iron, scrap steel, and recycle material are melted together, and the temperature of the molten iron is controlled to be 1460°C. Carry out spheroidizing treatment, the formula of spheroidizing agent is Mg 5.5wt%, Si 42wt%, Re 0.6wt%, the rest is iron, the addition amount of spheroidizing agent is the total amount of molten iron 1.15wt%, add covering on the spheroidizing agent The covering agent is a low-silicon, high-iron, Ba-silicon-containing ferrosilicon covering agent, and the amount of the covering agent added is 0.6wt% of the total amount of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com