Barium-strontium scale cleaning agent and preparation method thereof

A cleaning agent and strontium scale technology are applied in the field of barium strontium scale cleaning agent and preparation, can solve the problems of low scale removal efficiency, corrosion of metal equipment and the like, and achieve the effects of simple and feasible preparation method, low cost and wide sources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

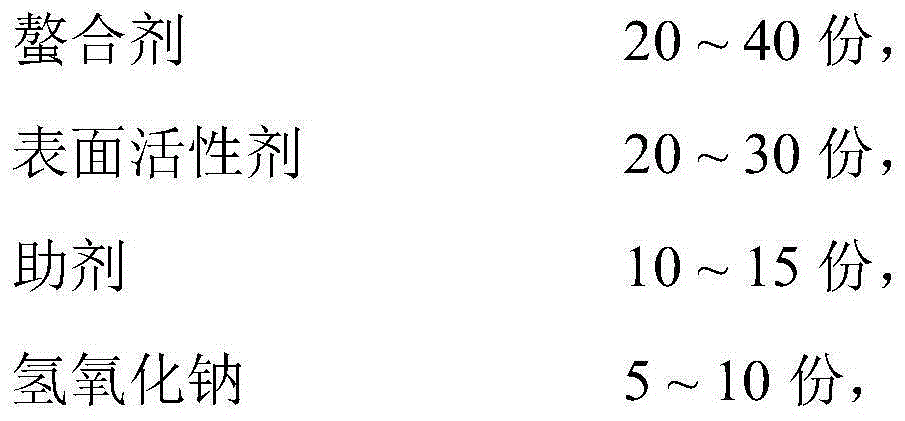

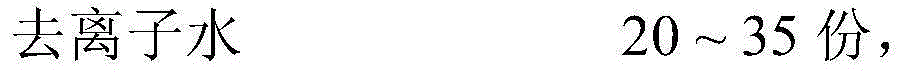

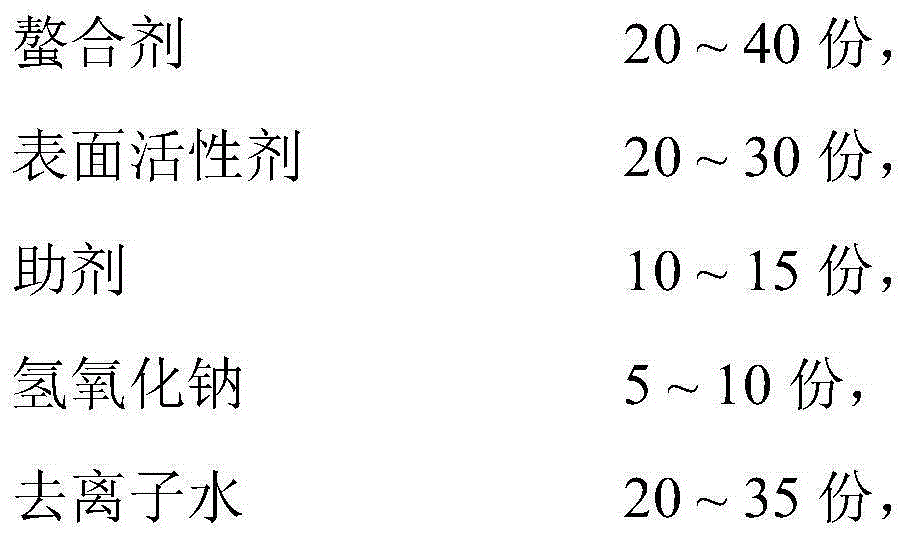

Method used

Image

Examples

Embodiment 1

[0027] Add 30 parts by weight of deionized water, 30 parts by weight of EDTA-2Na and 5 parts by weight of sodium hydroxide into the reaction flask, stir evenly, and react for 1 hour at a temperature of 40°C, then add them to the reaction flask in sequence Stir 20 parts by weight of Span-80 and 15 parts by weight of oxalic acid evenly, continue the heat preservation reaction for 1 hour, and naturally cool to room temperature to obtain a light yellow liquid that is the barium strontium scale cleaning agent.

Embodiment 2

[0029] Add 35 parts by weight of deionized water, 20 parts by weight of EDTA-2Na and 10 parts by weight of sodium hydroxide into the reaction flask, stir evenly, and react for 2 hours at a temperature of 50°C, then add them to the reaction flask in sequence Stir 20 parts by weight of Tween-60 and 10 parts by weight of oxalic acid evenly, continue to keep warm for 1.5 hours, and cool naturally to room temperature. The obtained light yellow liquid is the barium strontium scale cleaning agent.

Embodiment 3

[0031] 25 parts by weight of deionized water, 40 parts by weight of EDTA-2Na and DTPA-5Na mixture (wherein the weight ratio of EDTA-2Na and DTPA-5Na is 2:3), and 5 parts by weight of sodium hydroxide are added to the reaction In the bottle, stir evenly, react at 40°C for 2 hours, then add 20 parts by weight of Span-80 and 10 parts by weight of oxalic acid to the reaction bottle, stir evenly, continue to keep warm for 2 hours, and naturally cool to room temperature , the obtained light yellow liquid is barium strontium scale cleaning agent.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com