Robot-based automatic welding apparatus especially for steel grating plate and working method thereof

A technology of automatic welding and steel grating, which is applied in welding equipment, welding/welding/cutting items, manipulators, etc., to meet welding requirements, increase welding speed, and prevent harm to the human body

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

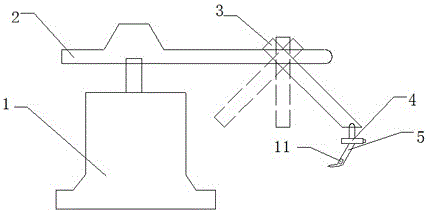

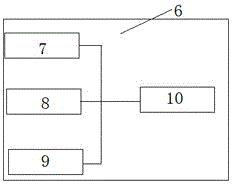

[0034] Such as figure 1 and figure 2 The shown robot automatic welding device for steel grating includes: fixed seat 1, horizontal shaft 2, first joint shaft 3, second joint shaft 4, welding torch 5 and control device 6, and also includes display screen, operation A keyboard and an alarm device, the control device 6 includes a welding device 7 , a sensor control system 8 , an execution device 9 and an automatic control system 10 .

[0035] The relationship between the above components is as follows:

[0036] The display screen is connected to the fixed seat 1 through the mechanical arm, the operation keyboard is set on the fixed seat 1, the fixed seat 1 is fixed on the ground by anchor screws, and the horizontal axis 2 is fixed by the positioning pin On the fixed seat 1, the described alarm device is arranged at one end of the horizontal axis 2,

[0037]The first joint shaft 3 is arranged on one end of the horizontal shaft 2 through a positioning pin, the second joint shaf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com