Cable laying system for high-altitude vertical structure body

A cable laying and structure technology, applied in the direction of cable laying equipment, etc., can solve the problems of difficult to control the downward inertia of the cable, wear of the cable insulation protection layer, and large downward inertia, so as to avoid mutual wear, ensure construction quality, The effect of increasing friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

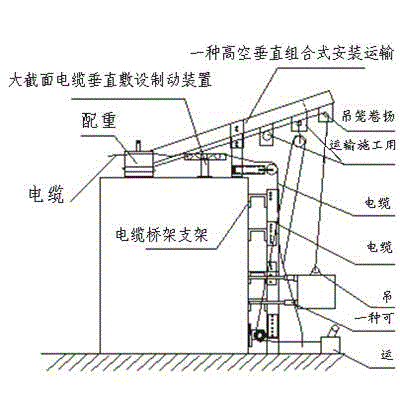

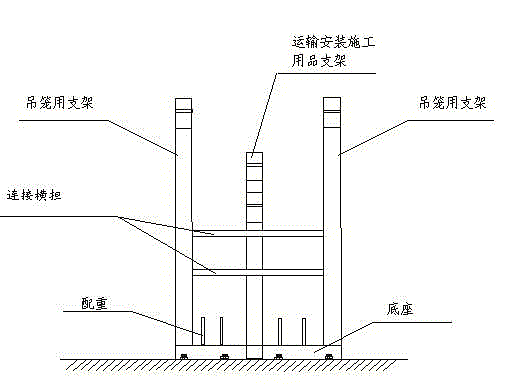

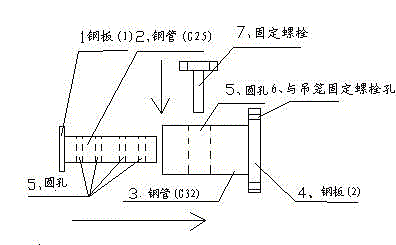

[0015] Such as Figure 1 to Figure 3 As shown, a cable laying system on a high vertical structure, which includes:

[0016] The high-altitude vertical combined installation transport device on the high-altitude construction platform includes a fixed base 1, legs 2, connecting cross arms 3, two cage brackets 4 and a transport and installation construction supplies bracket 5, the legs Located on the top edge of the vertical structure, the support is connected to the middle part of the bracket for the hanging cage and the bracket for the transportation, installation and construction supplies. The two brackets for the hanging cage are arranged on both sides of the bracket for the transportation, installation and construction supplies. Connect the cross-arm connection, the cage support is longer than the transport and installation construction supplies support, and its end is provided with a hanging cage hanging point, and the transport and installation construction supplies...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com