Battery pack

A technology for battery packs and battery units, which is applied to battery pack components, circuits, electrical components, etc., and can solve problems such as separation of upper and lower covers, inconvenient production rework, and no effective combination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020]

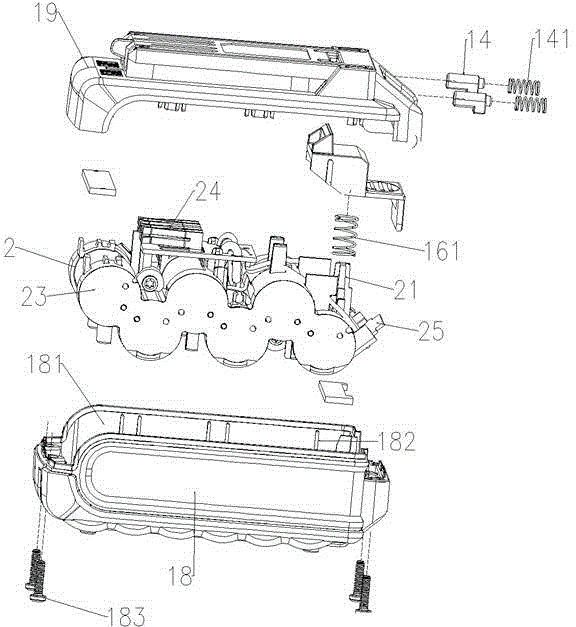

[0021] The present invention will be further described below in conjunction with the accompanying drawings.

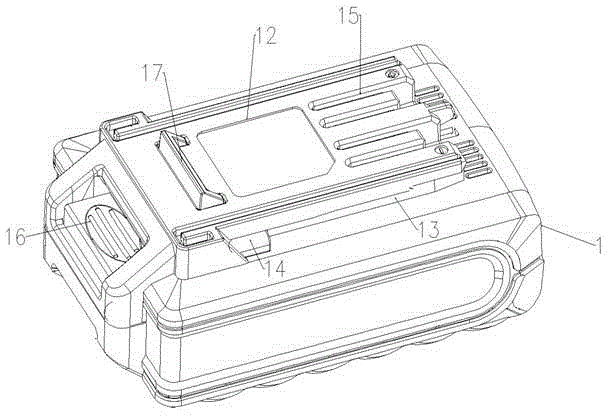

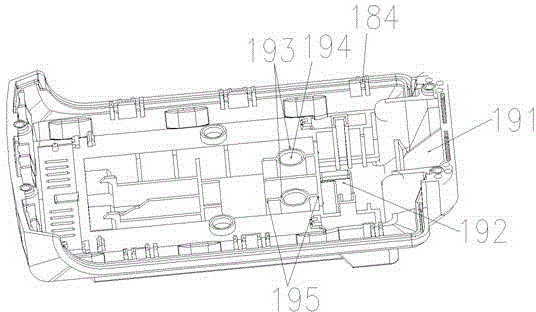

[0022] refer to figure 1 The battery pack shown has a casing 1 which is roughly in the shape of a cuboid. A square joint 12 protruding outward is provided on the upper surface of the battery pack, and slide grooves 13 are provided on both sides of the joint. The chute is used to slide at the position where the battery pack of the electric tool is installed, and the corresponding electric tool has a bracket structure (not shown in the figure) that cooperates with the chute. An elastic ejector 14 is provided at the end of the chute, and the elastic ejector is used to provide an auxiliary ejection function when taking out the battery. An electrode groove 15 is provided at the front end of the joint part 12, and the charging electrode and the discharging electrode of the battery pack are built in the electrode groove 15. When the electric tool and the battery p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com