LED display module group, and base frame disc and optical control circuit board both for same

A display module and base frame technology, applied in the direction of circuit layout, light source, point light source, etc., can solve the problems of heavy workload, impossibility of installation, bulky and large structure, etc., and achieve strong wind load bearing capacity, Easy installation and removal, low investment cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

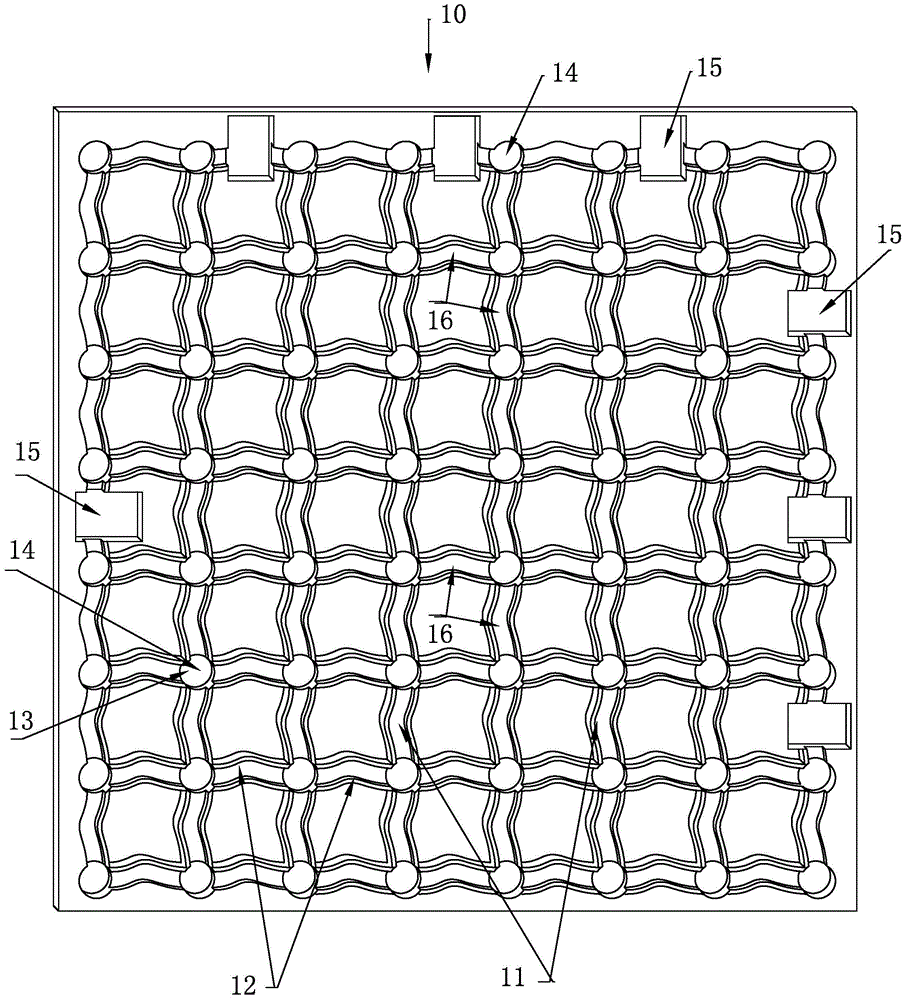

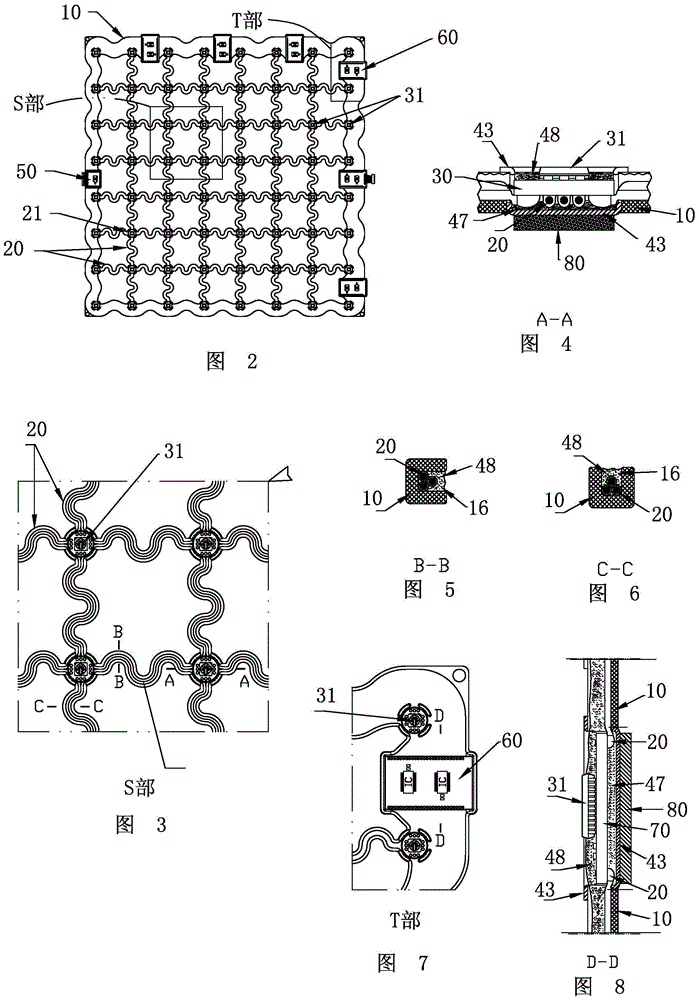

[0065] Such as figure 2 - Shown in 10: the LED display module of the present invention is made of soft plastic in the form of a checkerboard grid (see figure 1 ) pedestal plate 10 and the LED light control circuit board assembled on the pedestal plate 10 and the protective assembly 40 that can protect the electronic components on the LED light control circuit board from being waterproof, dustproof, impact resistant and anti-electromagnetic interference.

[0066] Several LED display modules of the present invention can be assembled into a large LED display curtain wall.

[0067] Now introduce each part of the module separately:

[0068] 1. Base plate 10

[0069] The base plate 10 is made of soft plastic by one injection molding, and it is composed of several meridian channels 11 and weft channels 12 that intersect horizontally and vertically. The space surrounded by the meridian channels 11 and the weft channels 12 forms a transparent mesh. A light source positioning hole 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com