Liquid crystal display with excellent antistatic performance and manufacturing method thereof

A liquid crystal display, anti-static technology, applied in the direction of static electricity, instruments, electrical components, etc., can solve the problems of poor anti-static performance, black shadow, unable to meet customer needs, etc., and achieve the effect of stable anti-static performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

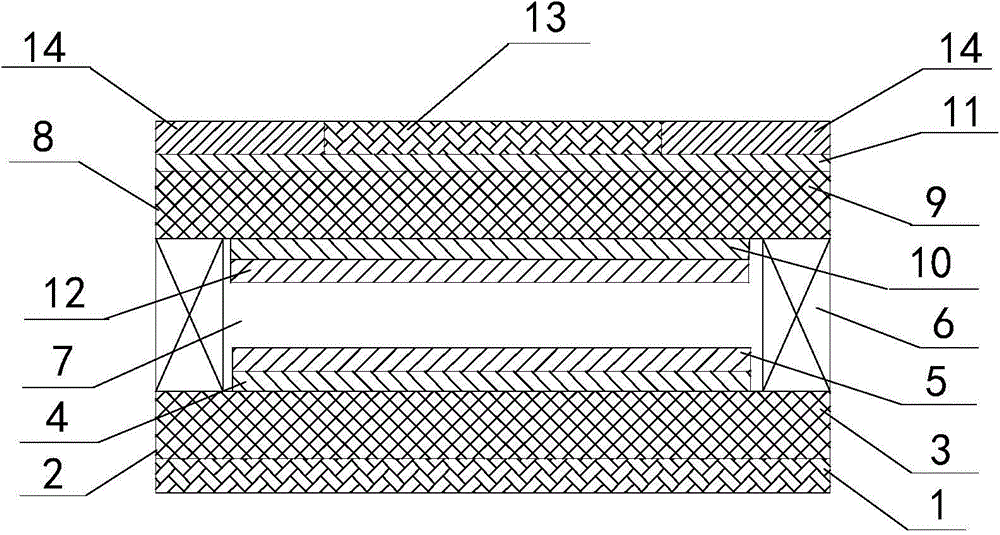

[0027] Embodiment 1: as figure 1 As shown, a liquid crystal display with excellent antistatic performance includes double-sided ITO glass 8, frame 6, bottom ITO glass 2 and bottom polarizer 1 arranged in sequence from top to bottom, double-sided ITO glass 8, frame 6 and bottom The ITO glass 2 forms a crystal storage space for placing the liquid crystal 7; the double-sided ITO glass 8 includes a face glass 9, a first ITO conductive layer 11 arranged on the upper surface of the face glass, and a first ITO layer etched on the lower surface of the face glass. The second ITO conductive layer 10 of the pattern, the first PI alignment layer 12 is provided on the second ITO conductive layer 10; The 3rd ITO conductive layer 4 of ITO pattern, the described 3rd ITO conductive layer 4 is provided with the second PI orientation layer 5; The viewing area on the described 3rd ITO conductive layer 11 top is provided with plane polarizer 13, the 3rd A conductive cloth 14 is provided outside t...

Embodiment 2

[0033] Embodiment 2: basically the same structure as Embodiment 1, the similarities are no longer repeated, and the differences are:

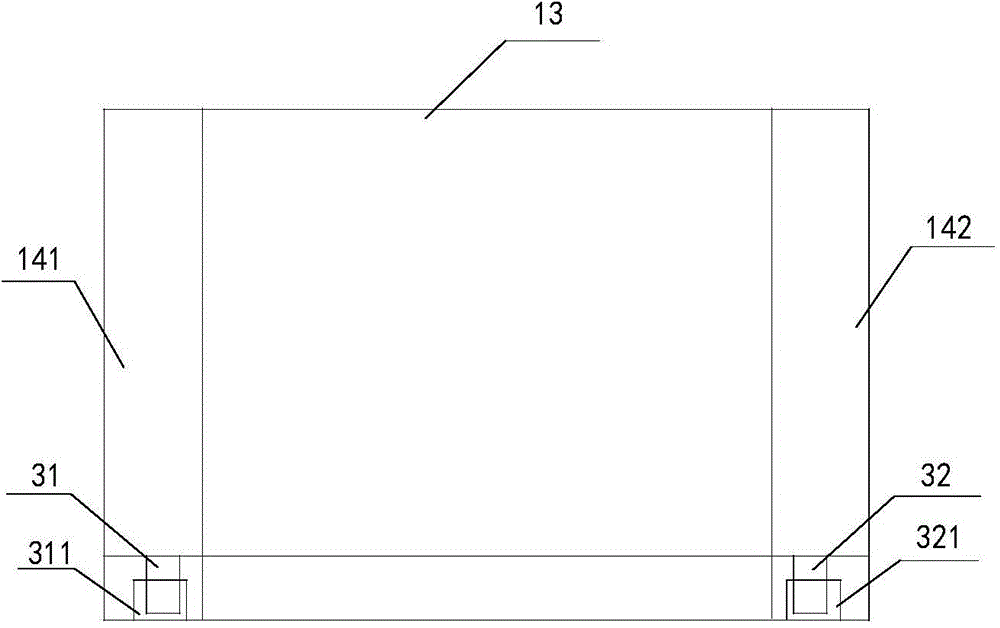

[0034] Such as figure 1 , figure 2 As mentioned above, the electrostatic lead-out device is a combination of step electrodes and conductive pins; one end of the bottom glass 3 is flush with the face glass 9, and the other end is longer than the face glass 9, and the lead area is that the bottom glass is longer than the face glass. part of the upper surface, the lead area is respectively provided with a first step electrode 31, a second step electrode 32; the upper part of the first ITO conductive layer 11 is horizontally provided with a first conductive cloth 141, a viewing area, a second Conductive cloth 142, the sum of the areas of the first conductive cloth 141, the viewing area, and the second conductive cloth 142 is equal to the area of the upper surface of the first ITO conductive layer; one end of the first conductive cloth 141 exten...

Embodiment 3

[0035] Embodiment 3: basically the same structure as Embodiment 1, the similarities are no longer repeated, and the differences are:

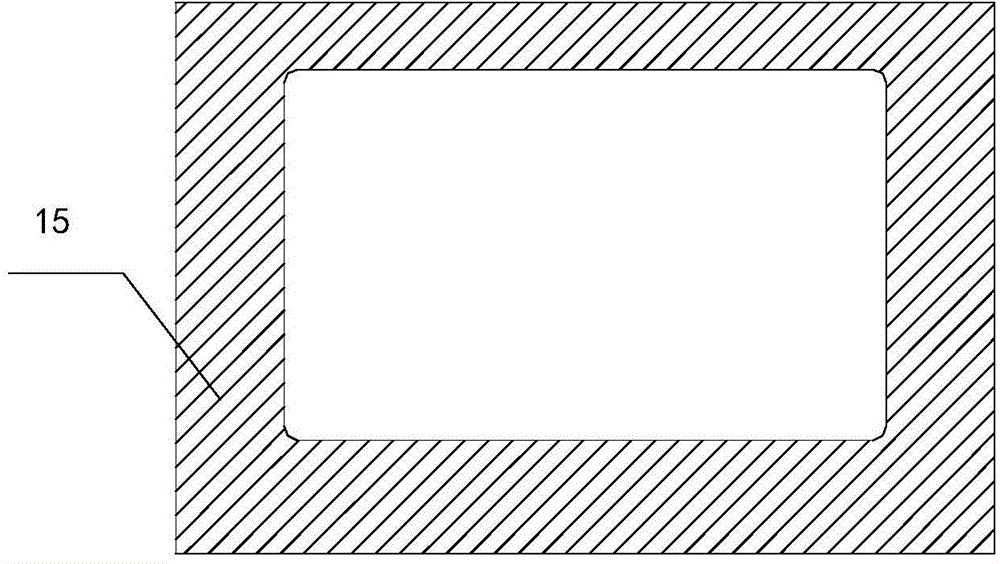

[0036] Such as figure 1 , image 3As mentioned, the static electricity extraction device is a metal frame 15 placed horizontally on the top of the liquid crystal display, one end of the face glass 9 is flush with the bottom glass 3, and the other end is longer than the bottom glass 3, and the lead area is that the face glass is longer than the bottom glass 3. The lower surface of the glass part, the metal frame is in contact with the conductive cloth outside the viewing area on the top of the first ITO conductive layer, the viewing area on the top of the first ITO conductive layer is located in the metal frame, and the metal frame is connected to the The PCB board is grounded.

[0037] The widths of the first conductive cloth and the second conductive cloth are both 2mm.

[0038] The outer side length of the metal frame matches t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com