A thermal wind speed sensor structure and calibration method with zero point calibration function

A wind speed sensor, zero point calibration technology, applied in the testing/calibration of speed/acceleration/shock measurement equipment, instruments, speed/acceleration/shock measurement, etc. The cost of calibration and the effect of convenient packaging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with the accompanying drawings.

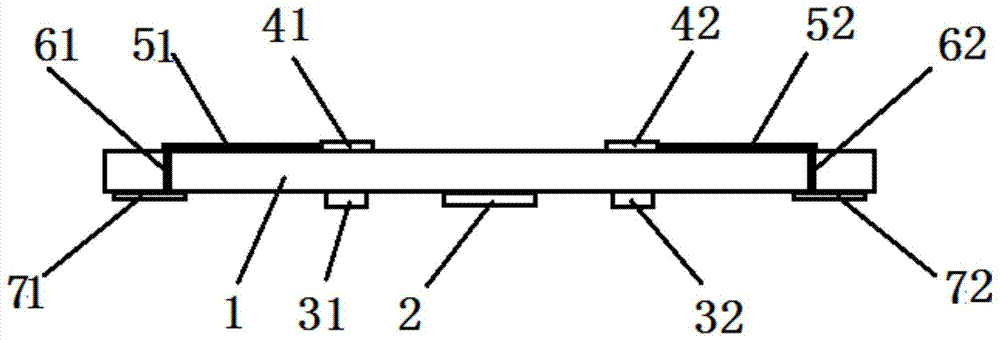

[0014] Such as figure 1 Shown is a thermal wind speed sensor structure with a zero point calibration function, including a circular ceramic substrate 1, a heating element 2 is arranged at the center of the back of the circular ceramic substrate 1, a first temperature measuring sensor 31 and a second measuring sensor The temperature sensors 32 are symmetrically distributed on the back of the circular ceramic substrate 1 with the heating element 2 as the center, and the first heating element 41 and the second heating element 42 are symmetrically distributed on the front of the circular ceramic substrate 1 with the heating element 2 as the center; The first heating element 41 is connected with the first lead pad 71 on the back side of the circular ceramic substrate 1 through the first wire 51 and the first through hole 61, and the second heating element 42 is connected wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com