Detection device and detection method for two-way wind speed and wind direction measurement

A technology of detection device and wind direction, which is applied in measurement device, velocity/acceleration/shock measurement, and fluid velocity measurement using differential pressure. Strong, eliminating hysteresis nonlinear characteristics, high measurement accuracy and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

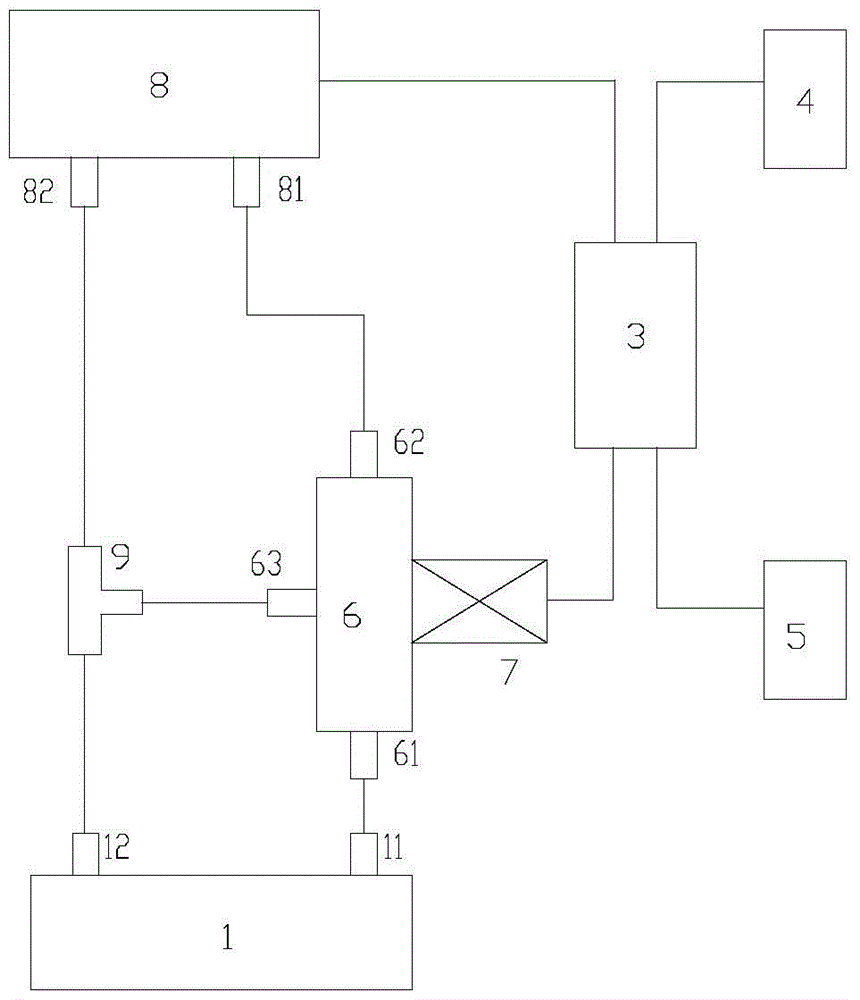

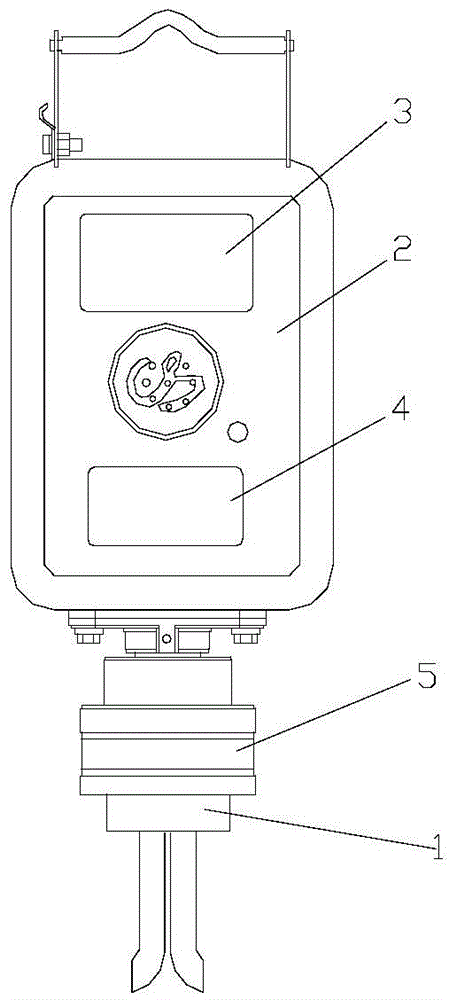

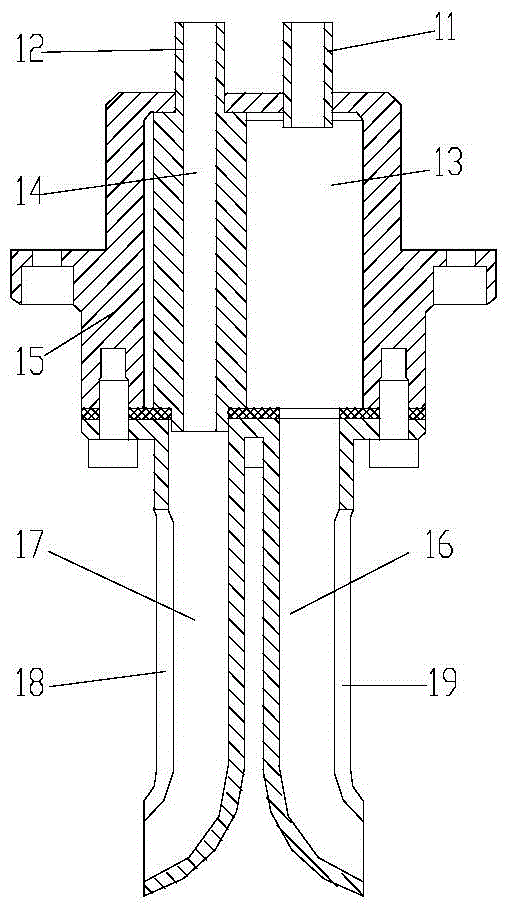

[0033] figure 1 It is a schematic block diagram of the present invention, and Fig. 2 is a structural representation of the present invention, image 3 It is a schematic diagram of the structure of the differential pressure sampling probe, Figure 4 for image 3 side view; as shown in the figure: the detection device for two-way wind speed and wind direction measurement of the present invention includes a micro-differential pressure sampling probe 1, an automatic zeroing assembly and a micro-pressure differential element 8; the micro-pressure differential element 8 generally adopts the existing The pressure sensor is made, so I won't repeat it here;

[0034] The micro-differential pressure sampling probe 1 includes a pressure introduction pipe I16 and a pressure introduction pipe II17 for sampling, and an air outlet I11 and an air outlet II12 correspondingly connected with the pressure introduction pipe I16 and the pressure introduction pipe II17, that is, the pressure introd...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com