A high temperature resistant silicone adhesive

A silicone and adhesive technology, applied in the direction of non-polymer adhesive additives, adhesives, adhesive additives, etc., can solve the problems of insufficient heat resistance in adhesion and mechanical properties, and achieve fast curing speed and good Adhesive performance and effect of high temperature resistance improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

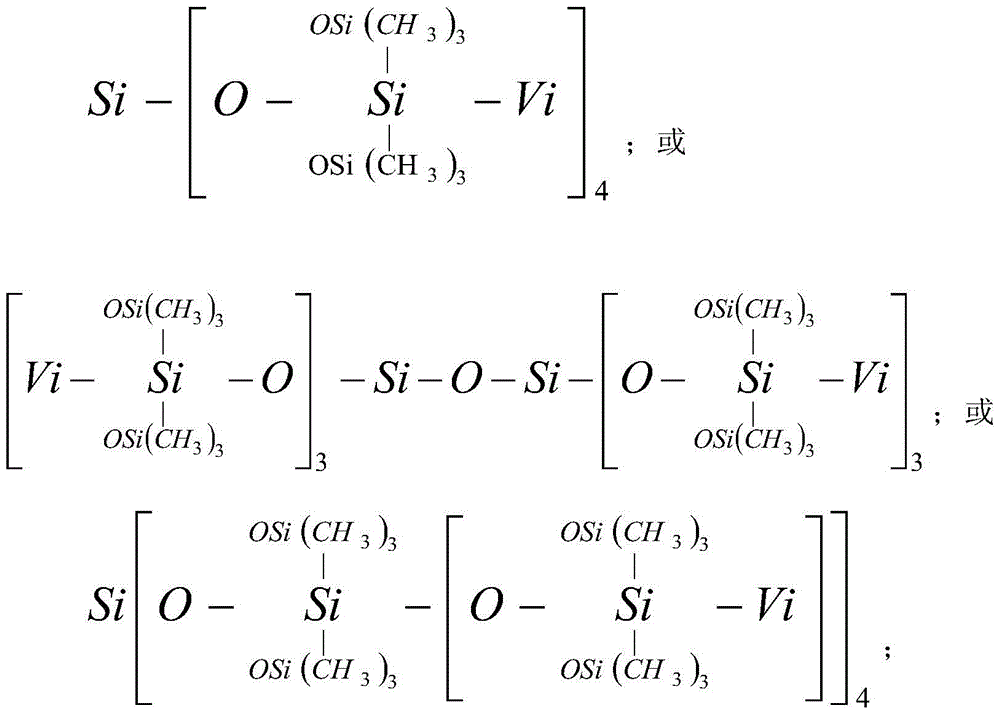

[0023] The vinyl-terminated polyorganosiloxane used in this example is a vinyl-terminated polydimethylsiloxane with a vinyl content of 2.5 wt% and a viscosity of 5000 centipoise; the reinforcing resin used is vinyl triethoxy Polysilane is a body-type vinyl-terminated polydimethylsiloxane with a vinyl content of 0.5 wt% formed by polycondensation of the core molecule with orthosilicate ethyl and ethoxytrimethylsilane, and its structural formula is:

[0024]

[0025] The toughening resin used is a mixture of octavinyl cage silsesquioxane with a vinyl content of 0.15 wt% and trapezoidal silsesquioxane with a vinyl content of 0.15 wt%; the crosslinked resin used is a hydrogen-containing 0.5% polymethylhydrogensiloxane.

[0026] Put 100 parts of vinyl-terminated polyorganosiloxane, 10 parts of reinforcing resin and 10 parts of toughening resin into a dynamic mixer and heat and stir under vacuum for 1 hour. The heating temperature is 110°C, and the vacuum degree is kept below -0....

Embodiment 2

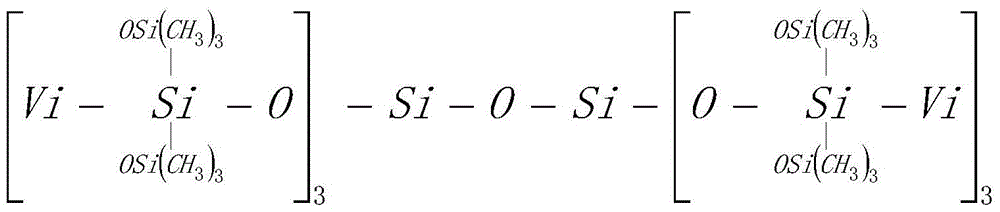

[0032] The vinyl-terminated polyorganosiloxane used in this example is a vinyl-terminated polydimethylsiloxane with a vinyl content of 0.008 wt% and a viscosity of 15,000 centipoise; the reinforcing resin used is vinyl triethoxy Silane is a bulk vinyl-terminated polydimethylsiloxane with a vinyl content of 2.5 wt% formed by polycondensation of the core molecule with orthosilicate ethyl and ethoxytrimethylsilane, and its structural formula is:

[0033]

[0034] a mixture of the two;

[0035]The toughened resin used is a mixture of octavinyl cage silsesquioxane with vinyl content of 0.2wt% and trapezoidal silsesquioxane with vinyl content of 0.2wt%; The resin is polymethylhydrogensiloxane with a hydrogen content of 1.5 wt%.

[0036] Put 100 parts of vinyl-terminated polyorganosiloxane, 30 parts of reinforcing resin and 30 parts of toughening resin into a dynamic mixer, heat and stir in vacuum for 2 hours, the heating temperature is 110 ° C, and the vacuum degree is kept be...

Embodiment 3

[0041] The vinyl-terminated polyorganosiloxane used in this example is vinyl-terminated polydimethylsiloxane with a viscosity of 80,000 centipoise and a vinyl content of 0.008 wt %; the reinforcing resin used is vinyl triethoxy The polydimethylsiloxane with a vinyl content of 2.5% is a bulk vinyl-terminated polydimethylsiloxane formed by polycondensation of polysilane as the core molecule with ethyl orthosilicate and ethoxytrimethylsilane. Its structural formula is:

[0042]

[0043] a mixture of the two;

[0044] The toughened resin used is a mixture of octavinyl cage silsesquioxane with vinyl content of 0.2wt% and trapezoidal silsesquioxane with vinyl content of 0.2wt%; The resin is polymethylhydrogensiloxane with a hydrogen content of 1.5 wt%.

[0045] Put 100 parts of vinyl-terminated polyorganosiloxane, 15 parts of reinforcing resin and 15 parts of toughening resin into a power mixer and heat and stir under vacuum for 2 hours. The heating temperature is 80 ° C, and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| shear strength | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com