Device and method for recycling phosphorus by virtue of induced crystallization

A technology of induced crystallization and seed crystals, which is applied in the fields of environmental protection and resource recycling, can solve problems such as difficult resource reuse, difficult regeneration, and limited adsorption capacity of adsorbent materials, so as to improve the effect of solid-liquid separation and reduce the use of chemicals The effect of increasing the amount and enhancing the phosphorus recovery effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0062] The induced crystallization reactor was used to recover phosphorus from the phosphorus-containing sewage configured in the laboratory. The height of the induced crystallization reactor is 30cm, the inner diameter is 16cm, the total volume is 6L, the effective volume is 5L, the effective volume of solid-liquid separation is 1.5L, the treated water volume is 1.67L / h, the hydraulic retention time is 3h, and the sewage comes from the laboratory configuration. For phosphorus-containing wastewater, add 43.9mg of potassium dihydrogen phosphate per liter of water, and its phosphorus concentration is 10mg / L.

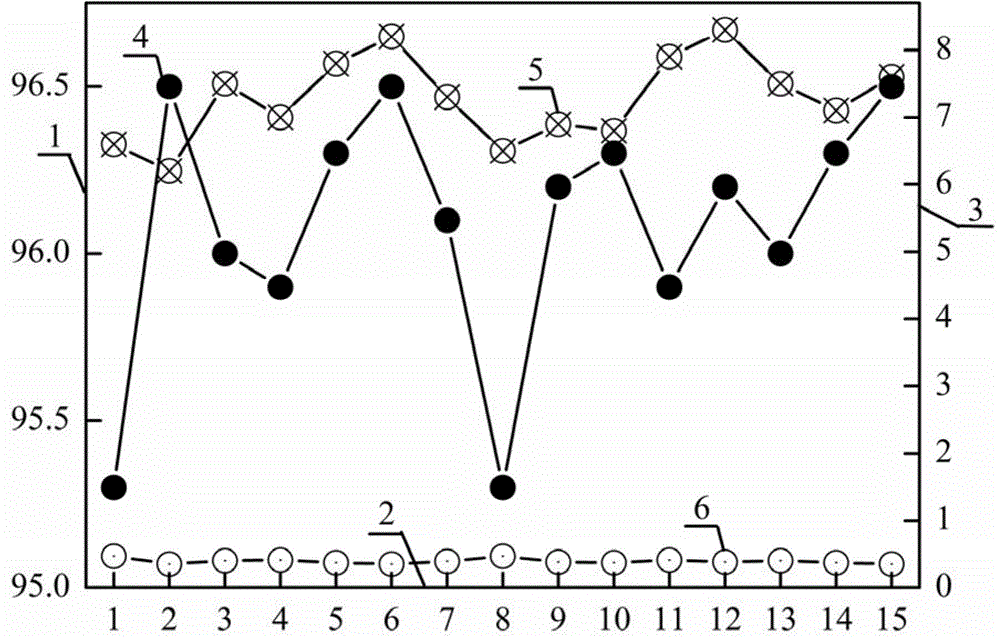

[0063] Take 600L of phosphorus-containing wastewater, add 3g of calcite seed crystals, adjust the pH to 8.8 with NaOH solution, and add CaCl at a Ca:P molar ratio of 2:1. 2 solution, the flow rate is 0.5L / h, and the aeration rate is 1.5L / min. The effluent was monitored continuously for 15 days, and the concentration of phosphorus in the effluent was measured every day. Th...

example 2

[0066] The induced crystallization reactor is used to recover phosphorus from urban domestic sewage. Take 1.2m of domestic sewage at the water inlet of a sewage treatment plant 3 , the treatment water volume is 3.30L / h, the hydraulic retention time is 3h, and 5g of calcite seeds are added, and the pH is adjusted to 8.8 with NaOH solution, and CaCl is added according to the Ca:P molar ratio of 2:1. 2 solution, the flow rate is 0.5L / h, and the aeration rate is 1.5L / min. Continuously monitor the influent and effluent for 15 days, and measure the concentration of phosphorus in the influent and effluent every day. See the test results image 3 .

[0067] According to the experimental results, the phosphorus concentration in the influent water is 6.2-8.3mg / L, the recovery rate of phosphorus in the sewage by the induced crystallization reactor is above 93%, and the phosphorus concentration in the effluent water is below 0.5mg / L, which meets the requirements of "GB18918-2002 Urban S...

example 3

[0069] The induced crystallization reactor is used to recover phosphorus from aquaculture wastewater. Take 0.3m of breeding wastewater at the outlet of a pig farm 3 , the treatment water volume is 0.85L / h, the hydraulic retention time is 3h, and 2g of calcite seeds are added, and the pH is adjusted to 8.8 with NaOH solution, and CaCl is added according to the Ca:P molar ratio of 2:1. 2 solution, the flow rate is 0.5L / h, and the aeration rate is 1.5L / min. Continuously monitor the influent and effluent for 15 days, and measure the concentration of phosphorus in the influent and effluent every day. See the test results image 3 .

[0070] According to the experimental results, the phosphorus concentration in the influent water is 38.8-45.9mg / L, the phosphorus recovery rate of the induced crystallization reactor in the sewage is above 83%, and the phosphorus concentration in the effluent water is below 8.0mg / L, which meets the requirements of "GB18596-2001 Livestock and Poultry ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com