Zipper coiling machine and coiling method

A winder and zipper technology, applied in the field of zipper manufacturing, can solve the problem of uneven chromaticity of zippers, and achieve the effect of simple and practical structure and uniform chromaticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below with reference to the drawings.

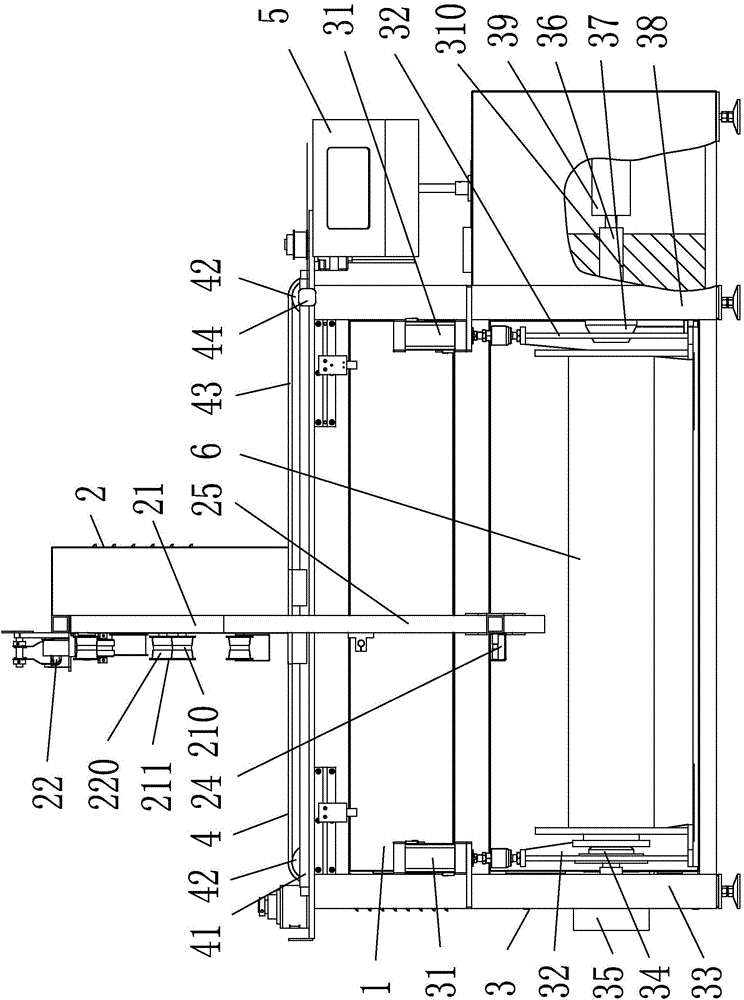

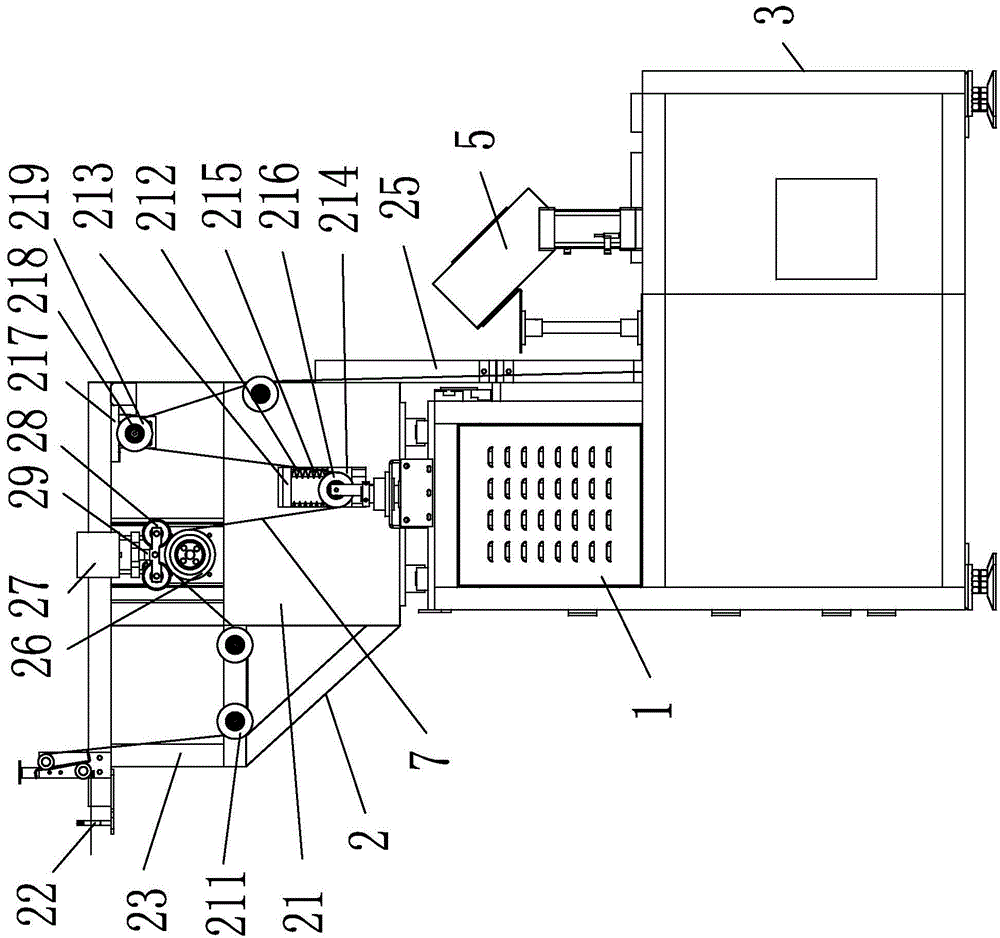

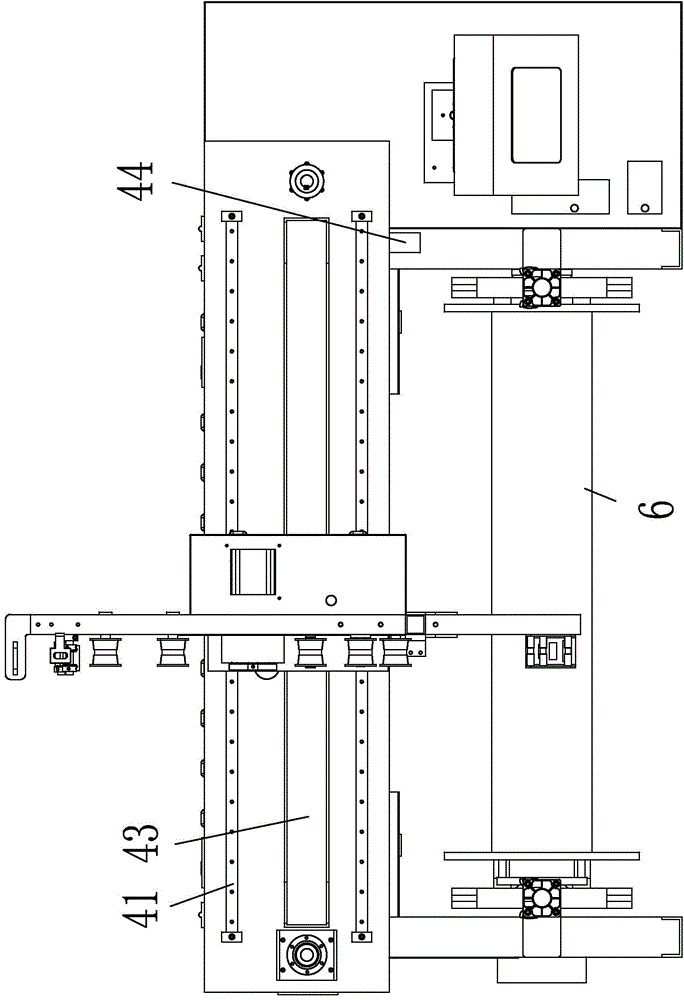

[0019] As attached figure 1 , Attached figure 2 , Attached image 3 Shown: a zipper winding machine, comprising a machine base 1, a machine head 2 connected with the machine base 1, a speed-regulating winding device 3, a machine head moving device 4, and a controller 5; the machine head 2 is provided with Speed measuring device.

[0020] The head 2 includes a frame 21, a rear guide frame 23 that is provided with a rear guide hole 22 and is screwed to the rear end of the frame 21, and is provided with a front guide hole 24 and is screwed to the front end of the frame 21 The front guide frame 25, the drive wheel 26 pivotally connected to the frame 21 through a bearing, is screwed to the frame 21, and the drive motor whose output shaft is keyed to the drive wheel 26 (shown in the drawing) is connected to the frame 21 The screw-connected double-rod cylinder 27 is provided with two pressi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com