A three-stage boneless wiper device

A three-stage, wiper technology, applied in transportation and packaging, vehicle cleaning, vehicle maintenance, etc., can solve the problems of long processing cycle, easy aging of products, long molding cycle, etc., and achieve good surface streamline and adaptable curvature Good performance and weight reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

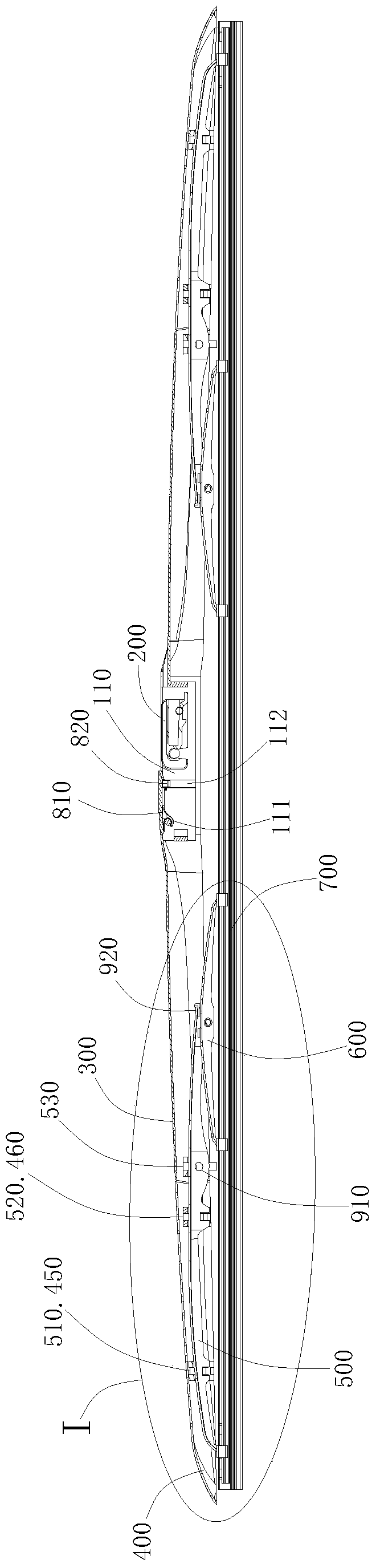

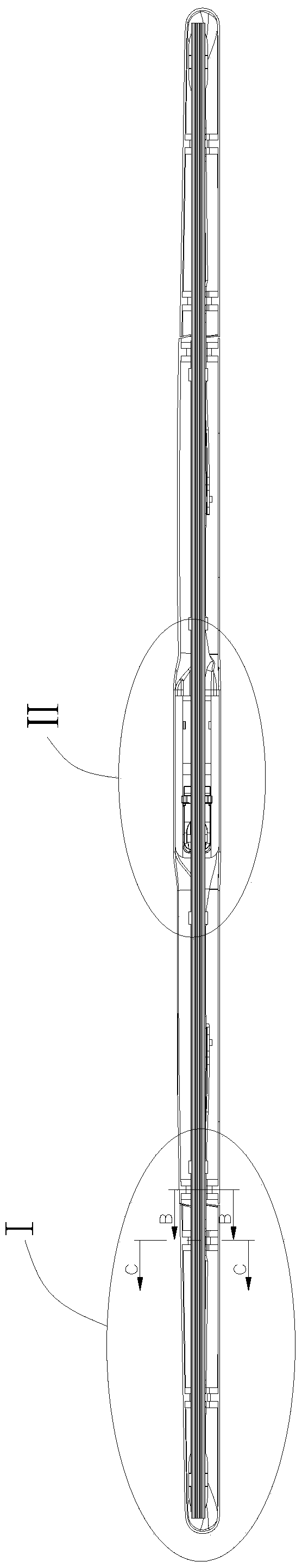

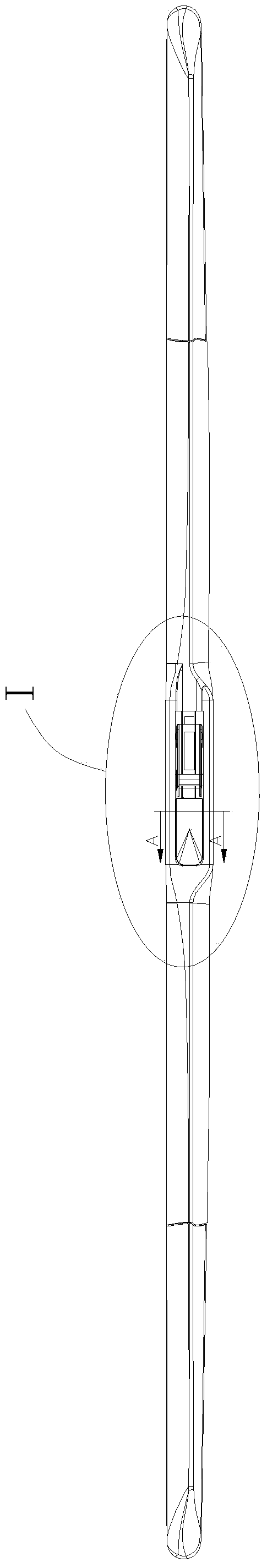

[0040] Referring to the accompanying drawings, a three-stage boneless wiper device is shown in the figure, including connectors 100, 200, a pair of decorative scraper frames 300, a pair of decorative scraper frames 400, a pair of middle scraper frames 500, a pair of A small wiper frame 600 and a wiper strip 700 .

[0041] An accommodating space 110 is provided in the connecting member 100, and the connecting member 200 is disposed in the accommodating space 110, and the connecting member 200 is connected with a rocker arm (not shown in the figure) of the wiper device. In addition, a decorative cover 800 is disposed on the accommodating space 110 , and the decorative cover 800 covers the area of the accommodating space 110 not filled by the connecting piece 200 . An elastic hinge arm 810 and a buckle 820 are arranged on the bottom surface of the decorative cover 800; a hinge shaft 111 and a buckle groove 112 are arranged in the accommodating space 110, and the free end of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com