Tea leaf screening machine

A screening machine and tea technology, applied in the direction of sieve, solid separation, grille, etc., can solve the problems of high manufacturing cost, complex structure, inconvenient disassembly and replacement of screen mesh, etc., and achieve the effect of remarkable vibration effect and convenient disassembly.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be described in further detail below in conjunction with accompanying drawing embodiment:

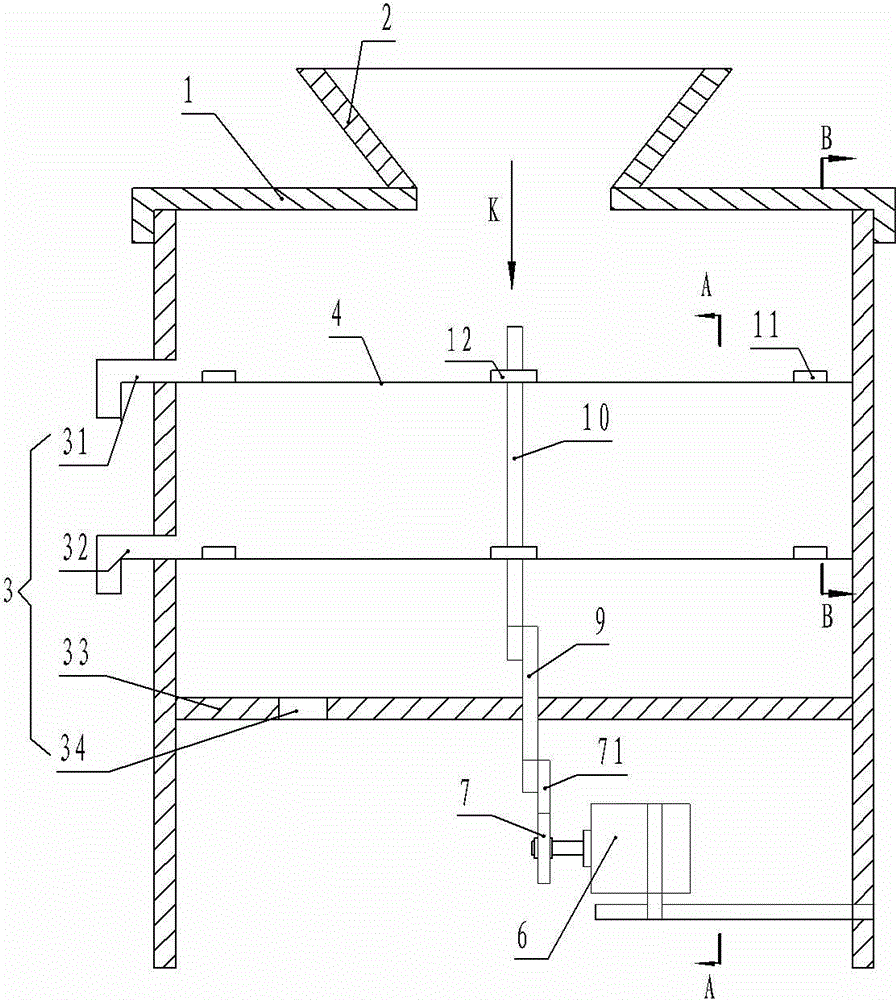

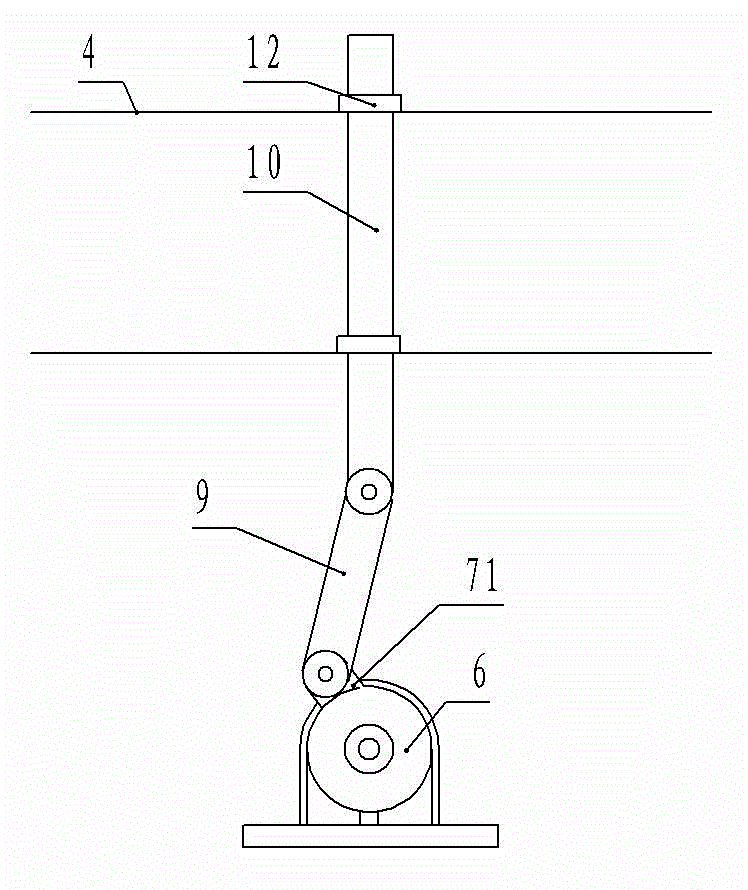

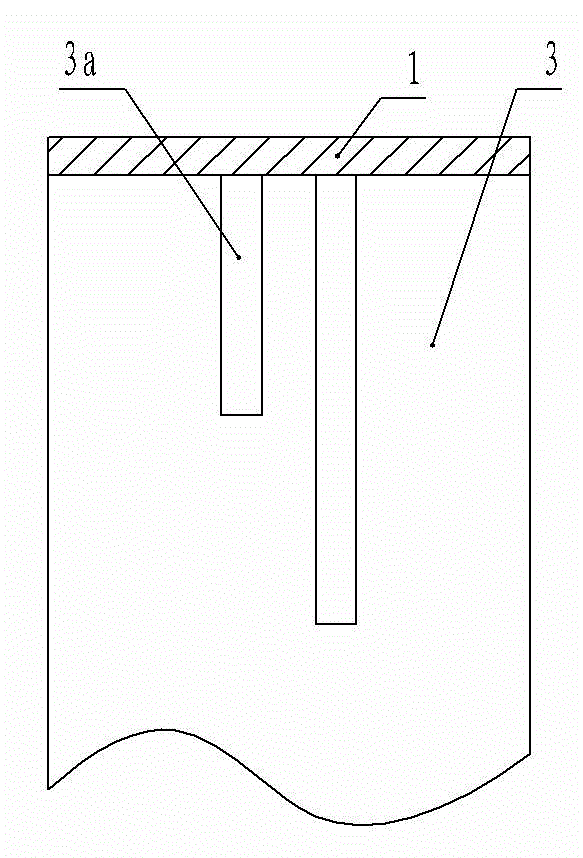

[0015] figure 1 The shown tea screening machine includes a screening machine body 3 with a base plate 33, a discharge port 34 is provided on the base plate 33, a top cover 1 is provided on the screening machine body 3, and a hopper 2 is provided on the top cover 1. Inlet, two layers of screens 4 are arranged in the screening machine body 3, and tea outlets 31, 32 are respectively provided on the side walls of the screening machine body 3 above each layer of screens 4; image 3 , Figure 4 As shown, the inner wall of the screening machine body 3 is provided with a plurality of mounting grooves 3a for the fixing of each layer of screens 4, the screens 4 are provided with positioning protrusions corresponding to the mounting grooves 3a, and the screens 4 are provided with Two handles 11; the aperture of the screen 4 decreases successively from top to bot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com