Centrifugal rotary conveyer and fish slaughtering machine provided with same

A conveyor and fish technology, applied in the direction of poultry/fish slaughter/stunning, etc., can solve the problems of unsafe slaughter, high labor intensity, high power consumption of equipment, etc., and achieve improved slaughter efficiency, fast slaughter speed, and transportation fast effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The technical solutions in the present invention will be clearly and completely described below in conjunction with the accompanying drawings in the present invention.

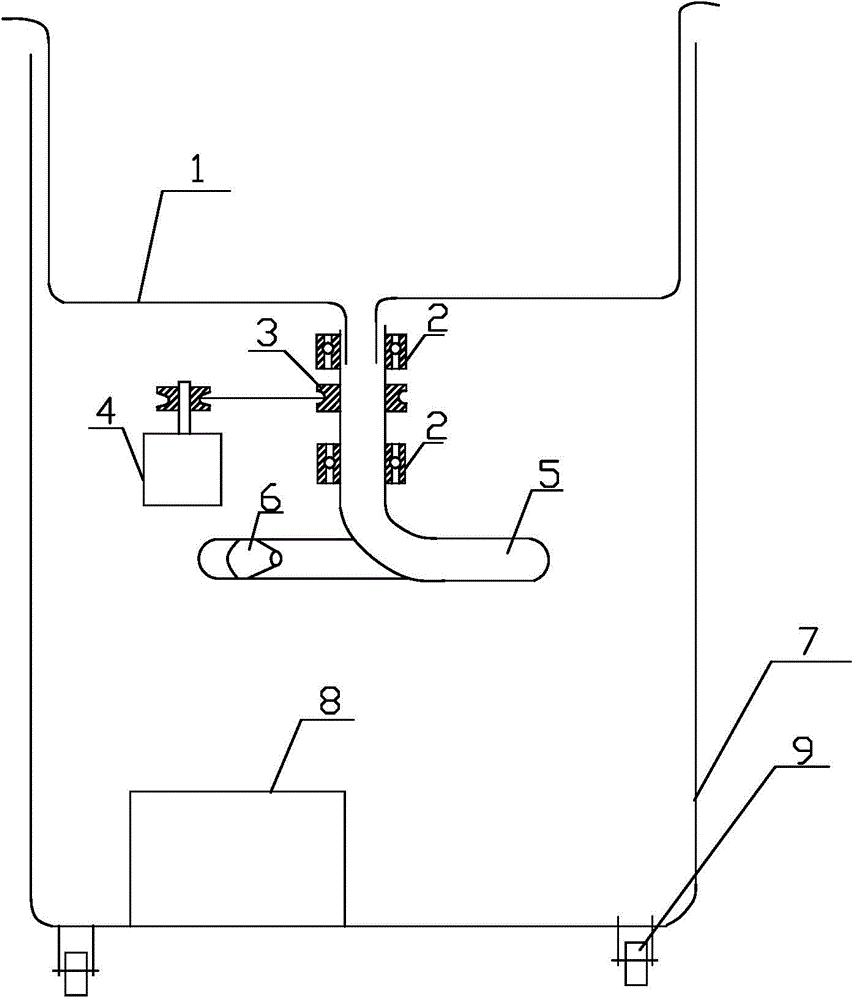

[0023] figure 1 Shown is the structure diagram of the fish slaughtering machine with centrifugal rotary conveyor of the present invention, said fish slaughtering machine with centrifugal rotary conveyor includes centrifugal rotary conveyor and dissection device 6 connected with centrifugal rotary conveyor .

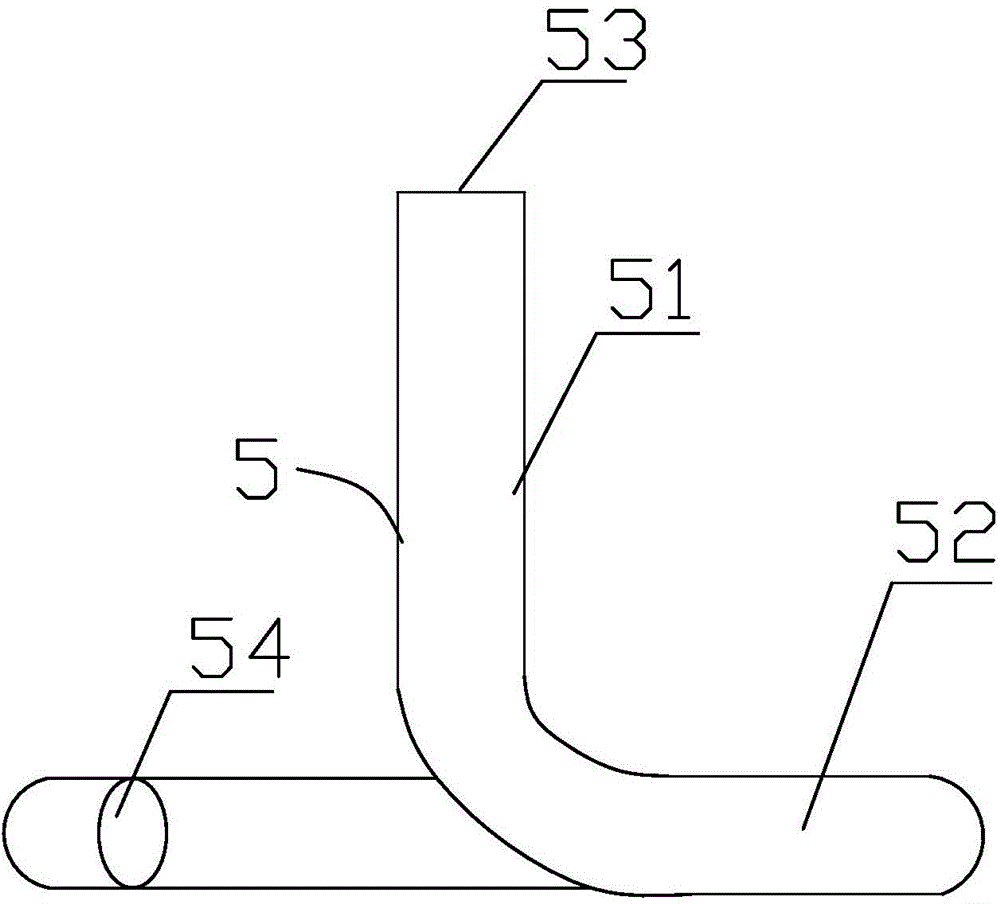

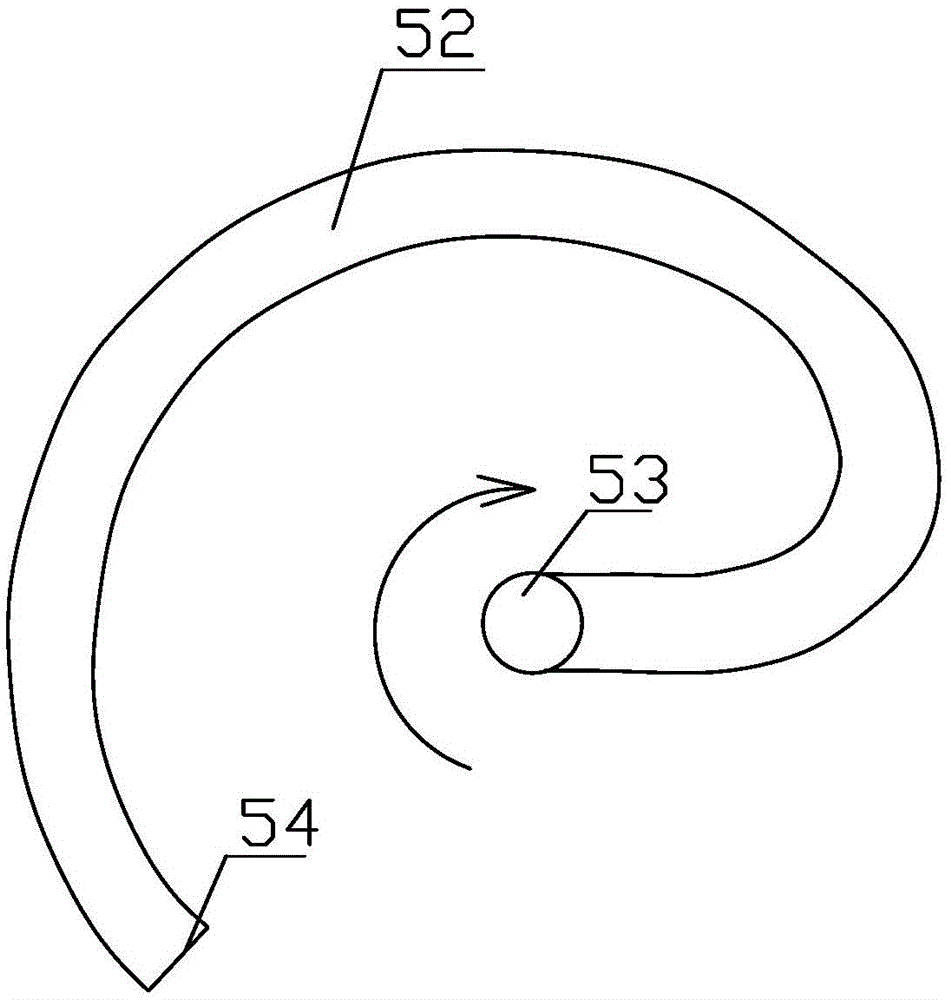

[0024] Please refer to figure 2 and image 3 The centrifugal rotary conveyor includes a storage hopper 1 and an involute rotary pipe 5 installed below the storage hopper 1. The involute rotary pipe 5 includes a vertical pipe body 51 connected to the outlet below the storage hopper 1 and The swivel pipe body 52 connected to the lower end of the vertical pipe body 51, the upper end opening of the vertical pipe body 51 is the swirl pipe inlet 53, which communicates with the outlet below the storag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com