Device and method for growing nitride monocrystal

A growth device and nitride technology, applied in the direction of single crystal growth, single crystal growth, crystal growth, etc., can solve the problems of hindering N entering the solution, slow crystal growth, low crystal quality, etc., to reduce production costs, promote dissolution, Reduce the effect of polycrystalline layers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

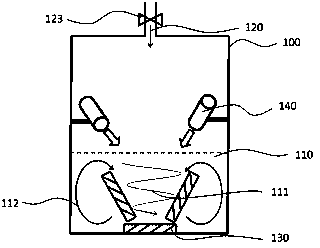

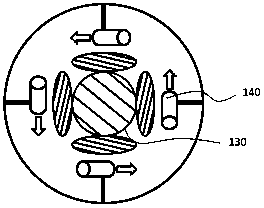

[0040] Embodiment one, as attached figure 1 , 2 As shown in and 3, a growth device for a nitride single crystal includes a reactor 100, the reactor 100 is filled with a growth solution 110, the bottom of the reactor 100 is provided with a seed crystal template 130, and the top of the reactor 100 is provided with a nitrogen gas inlet Inlet 120, the nitrogen gas inlet 120 is provided with a pressure regulating valve 123, and the reactor 100 is provided with a vortex generating device for forming a vortex in the growth solution. The vortex generating device is an air flow system 140 installed on the inner wall of the reactor. The air flow system includes an air guide tube 140 and a driver connected with the air guide tube to make the gas flow. The gas outlet terminal of the air guide tube 140 communicates with the inside of the reactor. The driver can be built into the air duct, and the driver operates to generate flow of nitrogen gas in the reactor. In addition, the driver for...

Embodiment 2

[0042] Embodiment two, as attached Figure 4 As shown, the structure of the second embodiment is basically the same as that of the first embodiment, and the vortex generating device in the reactor 200 is also an airflow system, the difference is that the airflow system in the second embodiment is located at the liquid level of the growth solution 220 in the reactor 200 below and above the seed template. The gas flow system includes an air guide tube 240 and a driver connected to the air guide tube to make the gas flow. The driver can be built in the gas guide tube, nitrogen enters from the nitrogen gas inlet 220 on the reaction kettle 200, and the nitrogen gas inlet can be adjusted by adjusting the pressure regulating valve 223 provided in the nitrogen gas inlet, and the driver runs to make the nitrogen gas in the reaction kettle 200 generate flow. Other drivers that make the gas flow can be existing known products, such as small driving fans or others as long as they can ge...

Embodiment 3

[0044] Embodiment three, as attached Figure 5 , 6 As shown in and 7, the main structure of the third embodiment is basically the same as that of the first embodiment, the difference lies in the specific structure of the eddy current generating device. A growth device for a nitride single crystal, comprising a reaction kettle 300 filled with a growth solution 310, a seed crystal template 330 is provided at the bottom of the reaction kettle 300, and a nitrogen gas inlet is provided at the top of the reaction kettle 300, and the nitrogen gas enters A pressure regulating valve 324 is provided in the air port, and a vortex generating device for forming a vortex in the growth solution is provided in the reactor 300 . The vortex generating device is a nitrogen pipeline system, and the nitrogen pipeline system includes a nitrogen inlet pipe 320 connected to the nitrogen inlet of the reactor 300, the nitrogen inlet pipe 320 is arranged in the reactor 300, and the nitrogen inlet pipe ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com