Concrete curing protective agent

A protective agent and concrete technology, applied in the field of building materials, can solve problems such as low brightness, and achieve the effects of short curing time, improved compactness and hardness, and improved brightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] The concrete surface curing protective agent in this embodiment is made of the following raw materials in weight percentage: nano-silica (5-10nm) 20wt.%, lithium silicate 20wt.%, acrylate emulsion (solid content 50%) 20wt.%, sodium methylsilicate 8wt.%, benzyl alcohol 1wt.%, and the rest are deionized water. Dissolve nano-silica, silicate, acrylate, hydrophobic agent and film-forming aid in deionized water, stir quickly to get a milky white liquid, which is concrete curing protective agent.

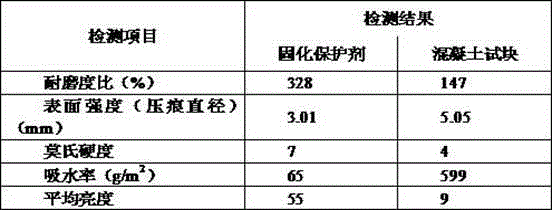

[0030] After using the above curing protection agent on the concrete surface, the ground performance test results are as follows (with the concrete test block without curing protection agent as a blank comparison):

[0031] Table 1

[0032]

Embodiment 2

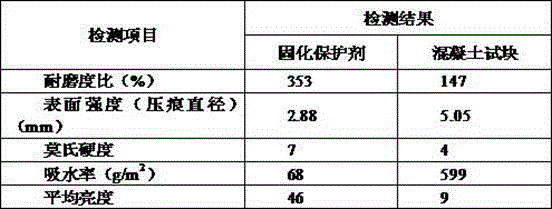

[0034] The concrete surface curing protective agent of this embodiment, in terms of weight percentage, is made of the following components: nano-silica (30-40nm) 28wt.%, sodium silicate 10wt.%, styrene-acrylate emulsion ( Solid content 50%) 32wt.%, siloxane 12wt.%, propylene glycol butyl ether 5wt.%, and the rest are deionized water. The preparation method is the same as in Example 1.

[0035] After using the above curing protection agent on the concrete surface, the ground performance test results are as follows (with the concrete test block without curing protection agent as a blank comparison):

[0036] Table 2

[0037]

[0038] In order to better embody the performance advantage of the present invention, some following comparative experiments were also made, and other unmarked conditions were the same as those in Example 1;

[0039] table 3

[0040] Nano silica Silicate Acrylate water repellent Coalescent Example 1 20wt.% 20wt.% 20wt.% ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com