Cylinder suction cup machine and gantry frame type cantilever suction cup machine

A cylindrical suction cup machine, suction cup machine technology, applied in the direction of conveyor objects, furnaces, lighting and heating equipment, etc., can solve the problems of single-arm guide rails that are easy to twist, hurt personal safety, and will tilt

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the accompanying drawings.

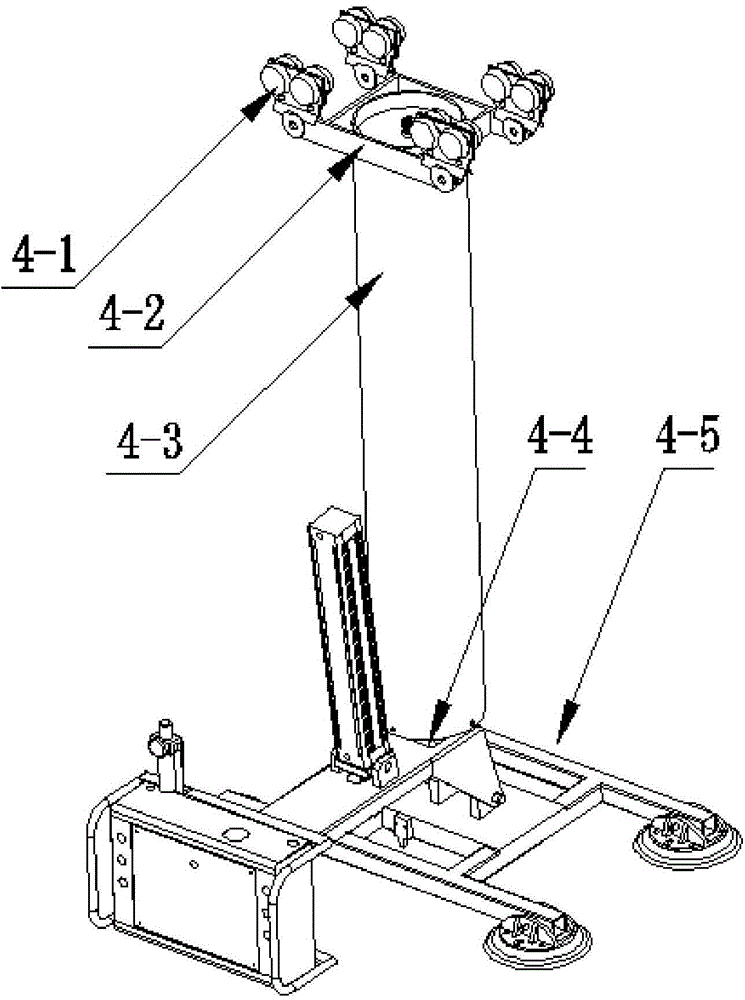

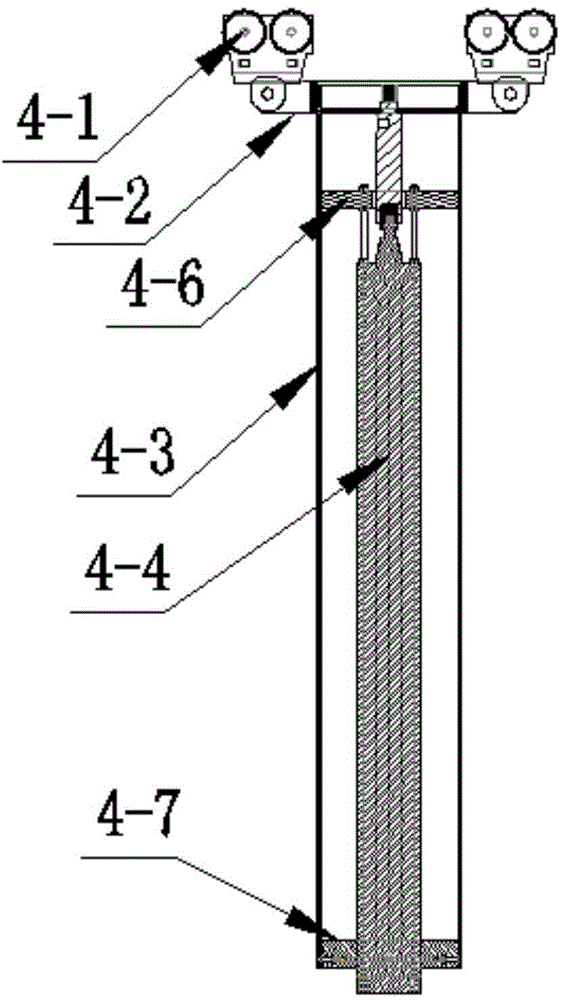

[0024] Such as figure 1 and figure 2 As shown, a cylindrical suction cup machine includes a track trolley 4-1, a cylindrical support 4-2, a circular steel cylinder 4-3, a vertical lifting cylinder 4-4, a suction cup support 4-5, and a cylinder guiding sliding disc 4-6, cylinder fixed disc 4-7;

[0025] The shaft of the vertical lift cylinder 4-4 is fixed with the cylinder support 4-2 by a plane bearing, and the shell of the vertical lift cylinder 4-4 is fixed on the cylinder guiding slide disk 4-6, and the shell of the vertical lift cylinder 4-4 Sliding with the cylinder guide sliding disc 4-6 to reach the elongation and contraction of the vertical lift cylinder 4-4, the fixed disc 4-7 of the cylinder is fixed with the circular steel cylinder 4-3 with bolts, and is connected with the vertical lift cylinder 4-4. The shell of 4 maintains a gap of 0.3 ~ 0.5mm for the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com