A belt conveyor mobile unloading device

A belt conveyor and unloading device technology, which is applied to conveyor objects, transportation and packaging, etc., can solve the problems of increasing the height of the transfer station, shortening the service life, limited upper and lower space, etc., and achieves a simplified process layout and compact equipment structure. , the effect of reducing upfront costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

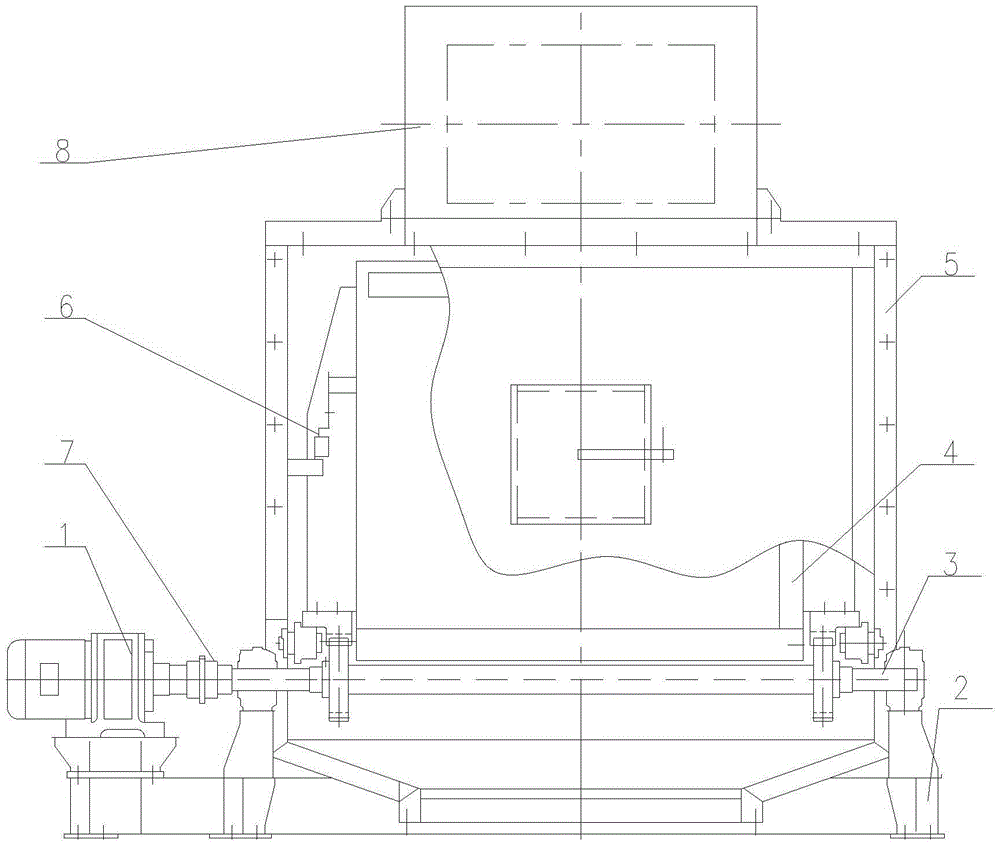

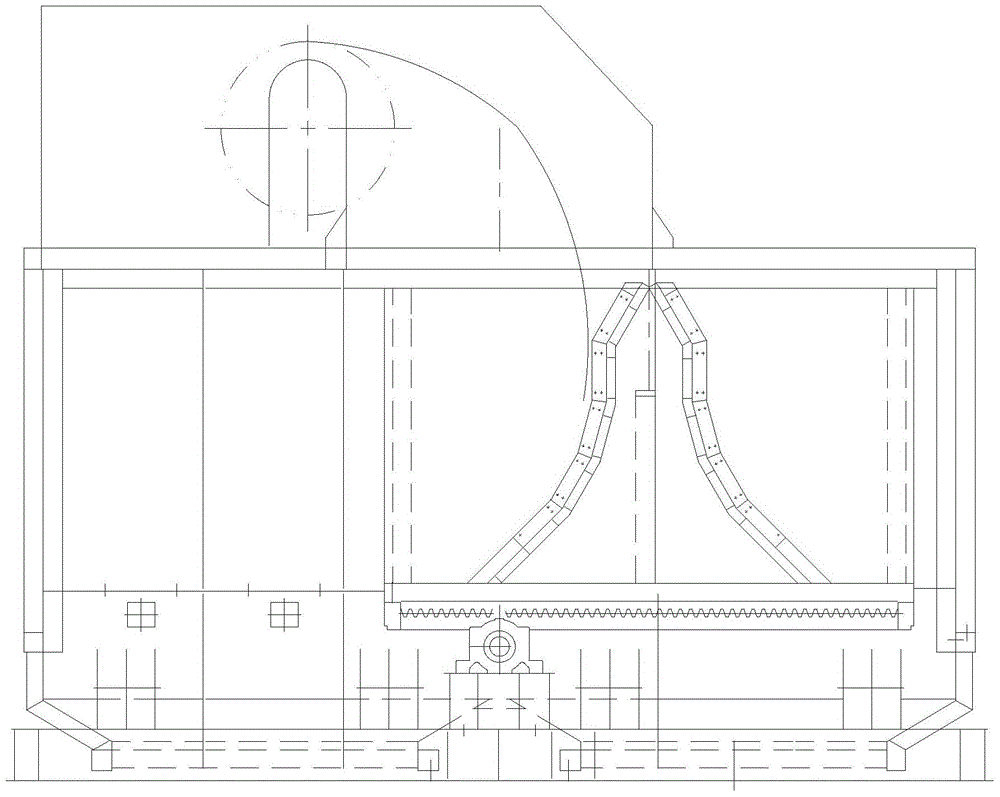

[0012] Referring to the accompanying drawings, a mobile unloading device for a belt conveyor includes a driving device 1, a base 2, a transmission device 3, a reversing baffle 4, a funnel body 5, a travel switch 6, a coupling 7, a head guard The cover 8 connects the driving device 1 and the base 2 with threads, the transmission device 3 runs through the funnel body 5, and is threaded with the base 2, and the shaft extension at one end of the transmission device 3 is connected with the drive device 1 by a coupling 7; the funnel body 5 and the The base 2 is threaded; the reversing baffle 4 is placed inside the funnel body 5, and the transmission device 3 is engaged with the chain on the reversing baffle 4, and the head shield 8 and the funnel body 5 are connected by flanges; Travel switches 6 are installed at both ends of the belt conveyor mobile unloading device.

[0013] The working principle of the mobile unloading device of the belt conveyor is that the driving device 1 is u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com