Wide plate chain conveying system of scraped car disassembly line

A technology for scrapping cars and assembly lines, applied in conveyors, transportation and packaging, etc., can solve the problems of low work efficiency, low degree of automation, poor safety, etc., and achieve the effect of improving work efficiency, reducing labor intensity and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with specific drawings.

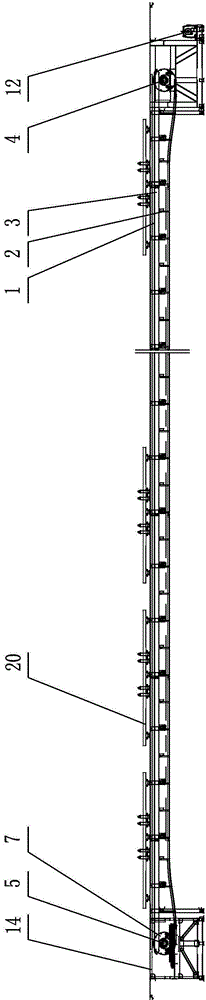

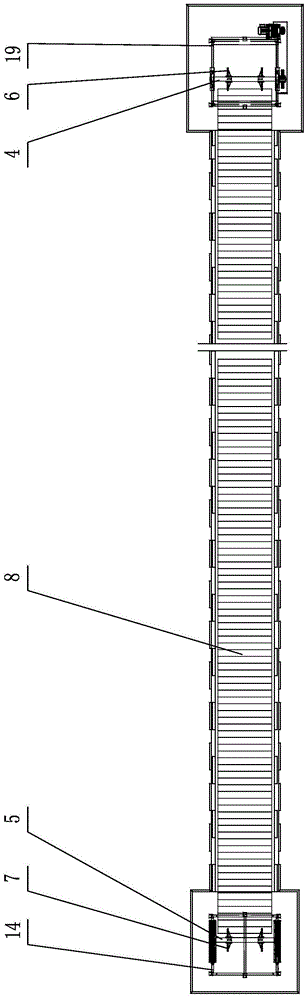

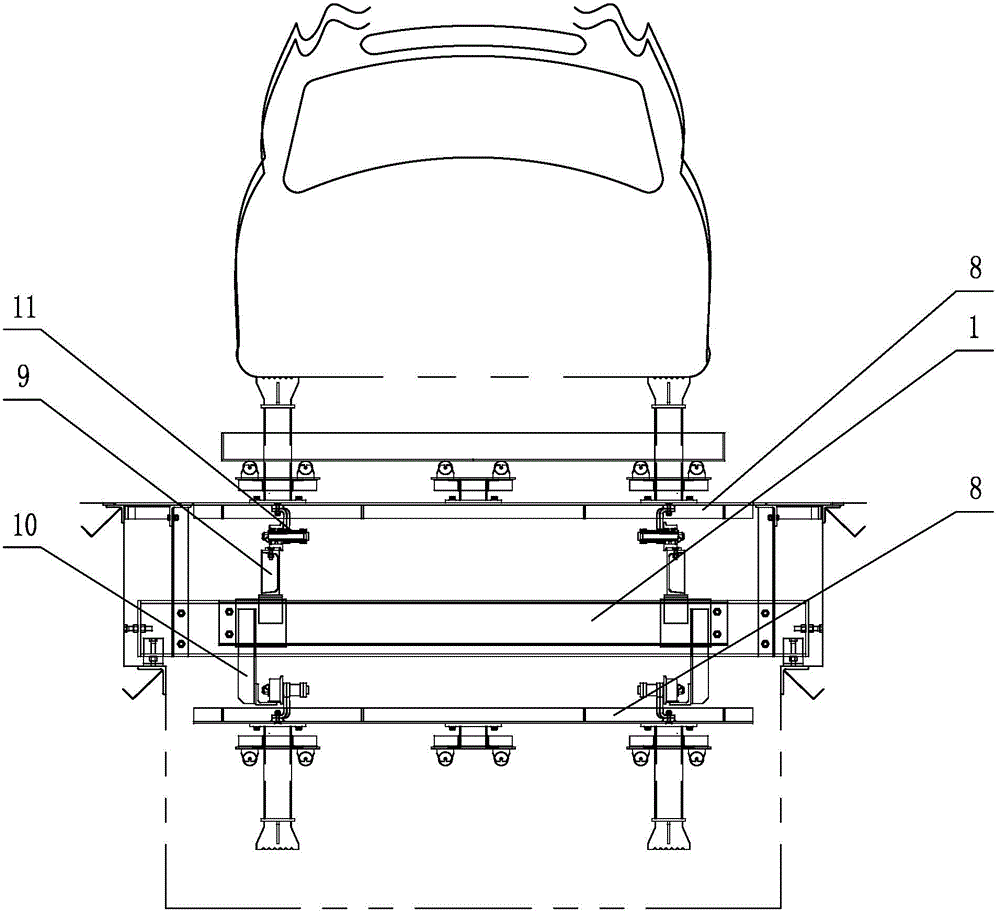

[0016] Such as Figure 1 to Figure 5 As shown: the wide plate chain conveying system of the scrapped automobile dismantling line includes a main bracket 1, a vertical bar 2, a horizontal bar 3, a driving shaft 4, a driven shaft 5, a driving sprocket 6, a driven sprocket 7, a panel 8. Upper track 9, lower track 10, traction chain 11, AC motor 12, drive chain 13, tension frame 14, transition mounting piece 15, screw rod 16, guide rail 17, fixed feet 18, drive frame 19, trolley tray 20, Drive sprocket 21 etc.

[0017] Such as figure 1 , figure 2 As shown, the present invention comprises a main support 1, a driving mechanism, a delivery mechanism and a tensioning mechanism. The driving mechanism and the tensioning mechanism are respectively located in the driving frame 19 and the tensioning frame 14 at the two ends of the main support 1, and the delivery mechanism is arranged ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com