Pearlescent laser paper and preparation process thereof

A preparation process, laser technology, applied in the direction of copying/marking methods, paper/cardboard layered products, lamination, etc., to achieve the effect of improving application grade, ideal surface flatness, and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

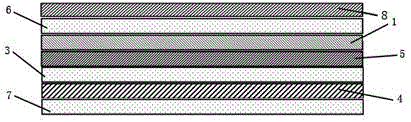

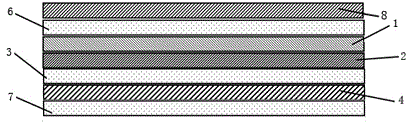

[0032] A pearlescent laser paper, such as figure 1 As shown, it includes a top coat 8, a laser layer 6, a pearlescent transfer layer 1, a plating medium layer 2, a transfer glue layer 3, a base paper 4 and a back coat 7 from top to bottom.

[0033] The preparation technology of above-mentioned paper comprises the following steps:

[0034] 1. Coating pearlescent pigments on the Bopp base film with radium layer 6 to form pearlescent transfer layer 1;

[0035] 2. Perform surface tension strengthening treatment on the pearlescent transfer layer 1;

[0036] Three, the pearlescent transfer layer 1 is plated with a medium to form a plated medium layer 2;

[0037] Four, the transfer glue is coated on the plating medium layer 2 to form the transfer glue layer 3;

[0038] 5. Carry out back coating on the back side of the base paper 4 to form a back coat 7, and then compound the front side of the base paper 4 with the transfer glue layer 3;

[0039] 6. Peel off the Bopp basement film...

Embodiment 2

[0049] A pearlescent laser paper, such as figure 1 As shown, it includes a top coat 8, a laser layer 6, a pearlescent transfer layer 1, an aluminum plating layer 5, a transfer glue layer 3, a base paper 4 and a back coat 7 from top to bottom.

[0050] The preparation technology of above-mentioned paper comprises the following steps:

[0051] 1. Coating pearlescent pigments on the Bopp base film with radium layer 6 to form pearlescent transfer layer 1;

[0052] 2. Perform surface tension strengthening treatment on the pearlescent transfer layer 1;

[0053] 3. Plating the pearlescent transfer layer 1 with aluminum to form the aluminum-coated layer 5;

[0054] Four, the transfer glue is coated on the aluminized layer 5 to form the transfer glue layer 3;

[0055] 5. Carry out back coating on the back side of the base paper 4 to form a back coat 7, and then compound the front side of the base paper 4 with the transfer glue layer 3;

[0056] 6. Peel off the Bopp basement film; ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com