Rubber-based thermal insulation layer patching method

A thermal insulation layer and rubber-based technology, which is applied in the field of solid rocket motor thermal insulation layer manufacturing, can solve the problems of inconvenient operation, long construction period of thermal insulation layer materials, high labor intensity, etc., and achieve long service life, good elasticity, and accelerated drying speed Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

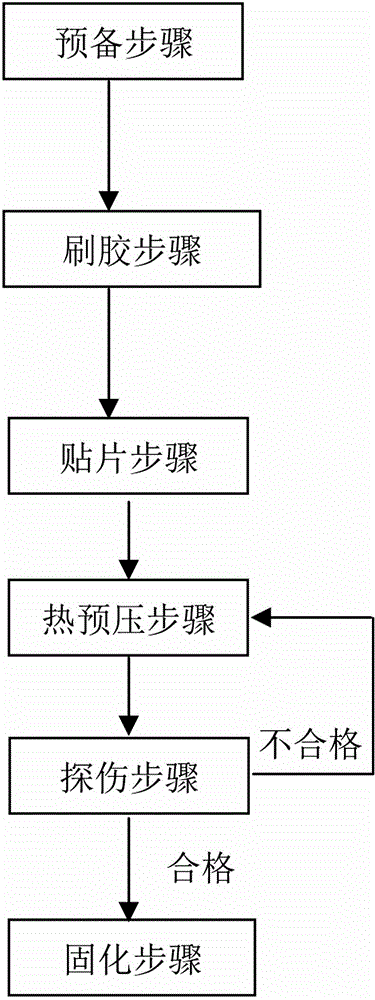

Method used

Image

Examples

Embodiment 1

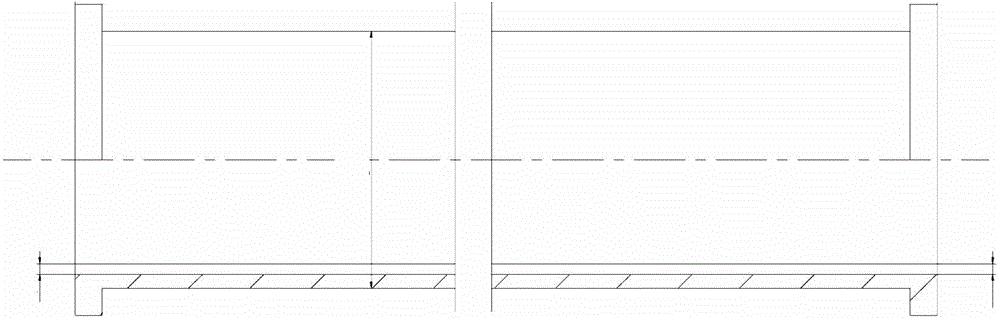

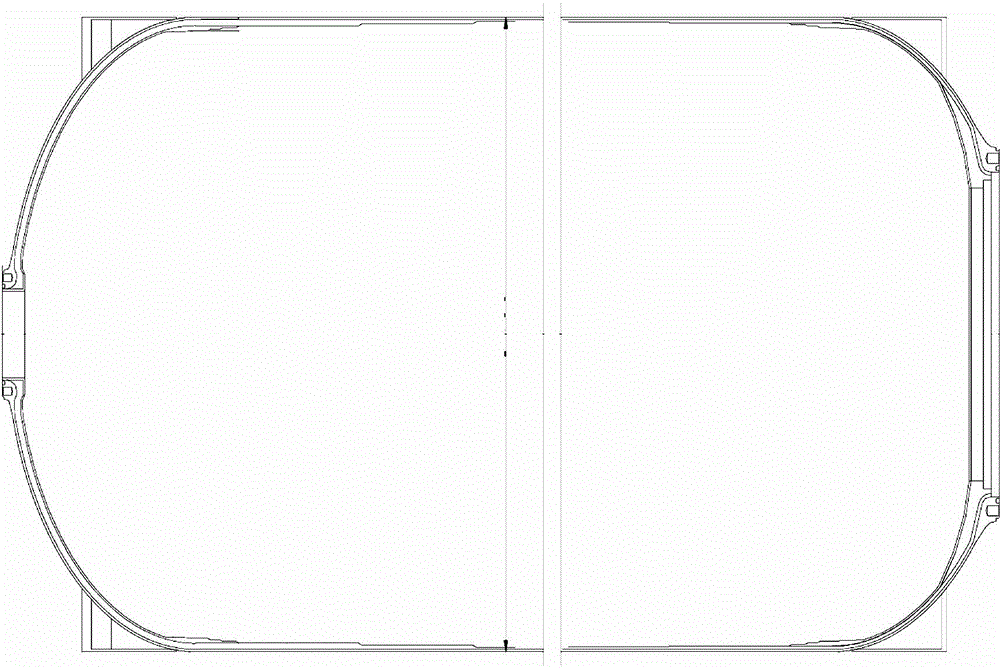

[0029] Such as figure 2 As shown, a solid rocket motor has a diameter of 220 mm and a length of 1600 mm. The inner wall is integrally pasted with a 4 mm thick heat insulating layer, and the heat insulating material used is nitrile rubber as the base heat insulating material;

[0030] 1) Preparatory steps: clean the inner surface of the engine housing with ethyl acetate solvent; manufacture the straight section heat insulation layer green sheet of the engine according to the design thickness requirements, the length of the green sheet is 1600mm, the width is 660mm, and the thickness is 4mm;

[0031] Manufacture rubber airbags, the specific material is silicone rubber, under the internal pressure of 0.1MPa, the outer diameter of rubber airbags is designed to be φ180mm, and the length is 1580mm;

[0032] 2) Glue brushing step: evenly brush the adhesive BM-1 inside the engine casing, the thickness of the adhesive film is 27μm-45μm, and let it dry for 2 hours;

[0033] 3) Laminat...

Embodiment 2

[0039] Such as figure 2 As shown, a solid rocket motor has a diameter of 220 mm and a length of 1600 mm. The inner wall is integrally pasted with a 4 mm thick heat insulating layer, and the heat insulating material used is nitrile rubber as the base heat insulating material;

[0040]1) Preparatory steps: Clean the inner surface of the engine shell with ethyl acetate solvent; manufacture the straight section heat insulation layer green sheet of the engine according to the design thickness requirement of 4mm, the length of the green sheet is 1600mm, the width is 660mm, and the thickness is 4mm;

[0041] Manufacture rubber airbags, the specific material is silicone rubber, under the internal pressure of 0.1MPa, the outer diameter of rubber airbags is designed to be φ180mm, and the length is 1580mm;

[0042] 2) Glue brushing step: evenly brush the adhesive BM-1 inside the engine housing, the thickness of the adhesive film is 27 μm ~ 45 μm, let it dry for 3 hours, evenly brush the...

Embodiment 3

[0049] Such as figure 2 As shown, a solid rocket motor has a diameter of 220 mm and a length of 1600 mm. The inner wall is integrally pasted with a 4 mm thick heat insulating layer, and the heat insulating material used is nitrile rubber as the base heat insulating material;

[0050] 1) Preparatory steps: Clean the inner surface of the engine shell with ethyl acetate solvent; manufacture the straight section heat insulation layer green sheet of the engine according to the design thickness requirement of 4mm, the length of the green sheet is 1600mm, the width is 660mm, and the thickness is 4mm;

[0051] Manufacture rubber airbags, under the internal pressure of 0.1MPa, the outer diameter of rubber airbags is designed to be φ180mm, and the length is 1580mm;

[0052] 2) Glue brushing step: evenly paint the adhesive BM-1 inside the engine housing, the thickness of the adhesive film is 27 μm to 45 μm, the heating temperature is 60°C, and the time is 1h. The thickness of the film ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com