Dry magnetic separator with introduced wind power and mineral magnetic separation method

A magnetic separator, dry technology, applied in chemical instruments and methods, magnetic separation, solid separation, etc., to achieve the effect of improving recovery rate, adjusting accuracy, and solving magnetic agglomeration and magnetic inclusions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in combination with specific embodiments and accompanying drawings.

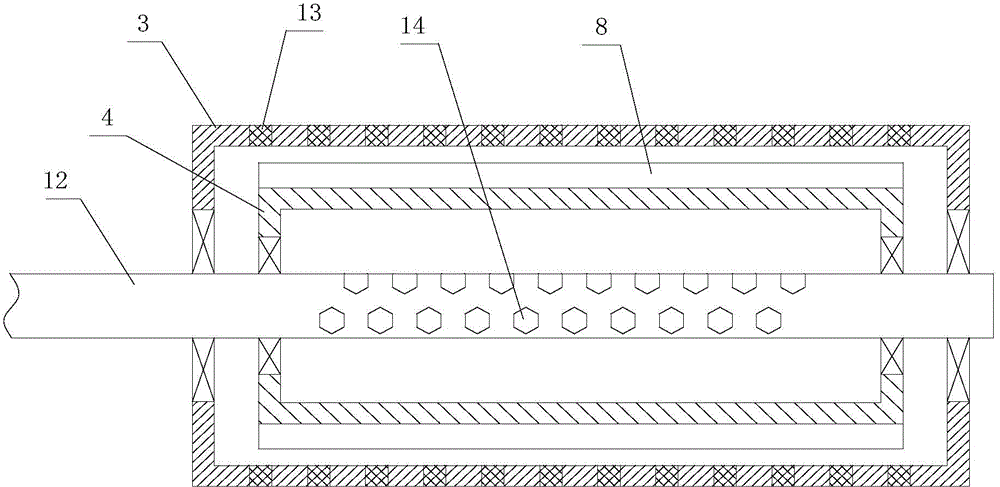

[0027] Such as Figure 1 to Figure 3 As shown, a dry magnetic separator introduced with wind power includes a casing 1, a feeding device 2, a ventilation roller 3, a magnetic roller 4, a discharge roller 5, a concentrate hopper 6 and a tailings hopper 7. The air-permeable roller 3 is horizontally rotated and installed in the shell 1, and the magnetic roller 4 is installed coaxially in the air-permeable roller 3. A number of ventilation holes are provided on the surface of the magnetic roller 4, and fixed along the circumference of the magnetic roller 4. The magnetic system is composed of permanent magnetic cores 8 uniformly arranged on the surface of the magnetic roller at equal intervals, and the magnetic poles of adjacent permanent magnetic cores 8 are different. The magnetic roller 4 rotates relative to the air-permeable roller 3 so as to form ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com