Cereal rice production system and production process thereof

A technology of production system and production process, which is applied in the field of miscellaneous grain rice production system and its production process, can solve the problems of uneven particle size, high energy consumption of production process, insufficient drying, etc., and achieve the goal of preventing colorectal cancer and obesity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

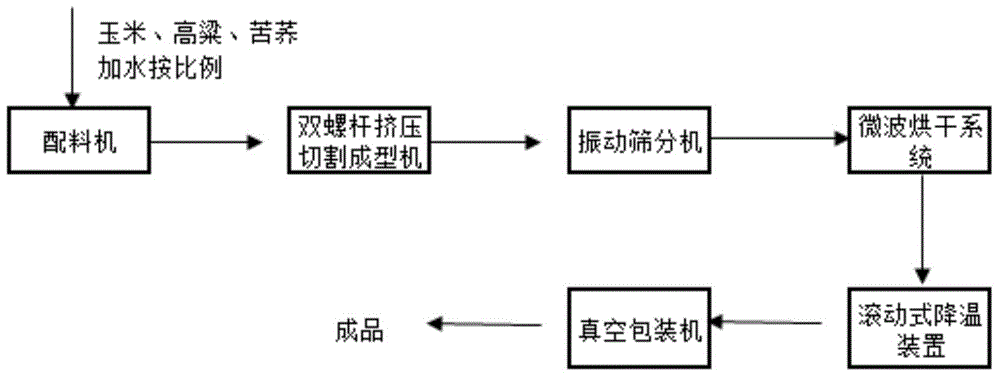

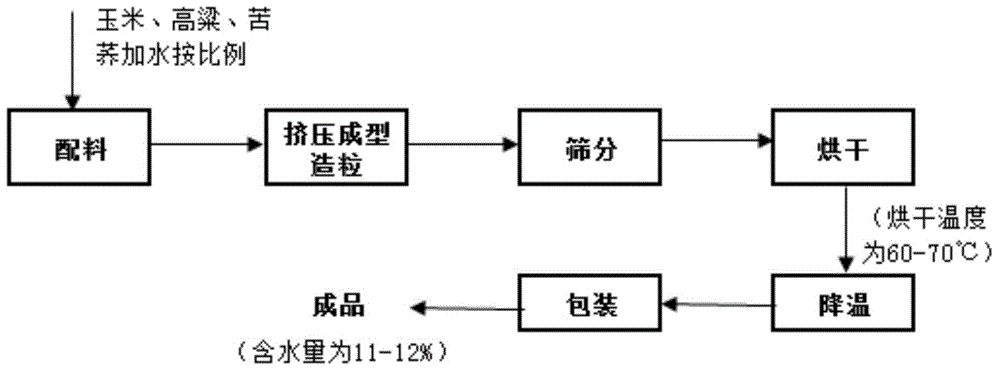

[0054] Such as figure 1 As shown, the multigrain rice production system of this embodiment mainly includes a batching machine, a twin-screw extrusion cutting machine, a vibrating screening machine, a microwave drying system, a drum cooling device and a vacuum packaging machine in sequence.

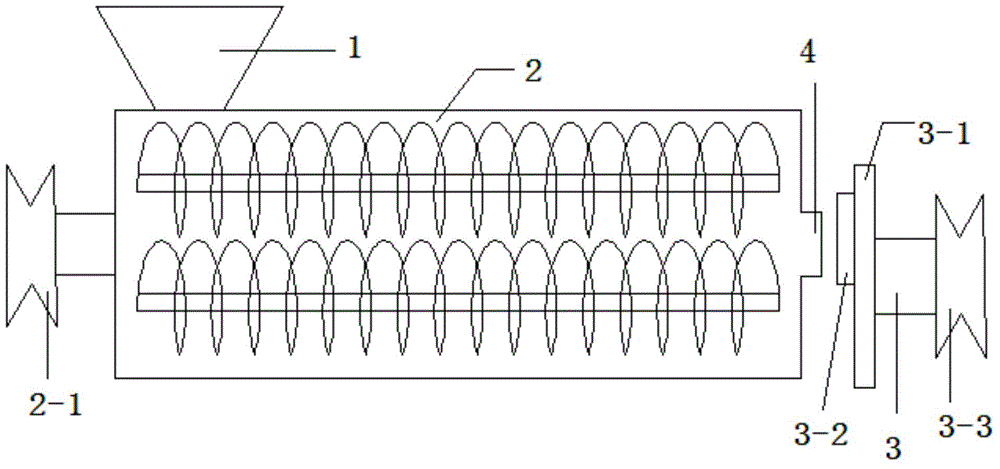

[0055] Such as image 3 , Figure 4 As shown, the twin-screw extrusion cutting molding machine includes a feeding device 1, a twin-screw extruder 2, an extrusion die 3 arranged at the end of the twin-screw extruder 2, and an extrusion port close to the extrusion die 3 The cutting device 4. The feeding device 1 is equipped with a material level control meter, which is connected with a conveyor, and the feeding speed is controlled by controlling the speed of the conveyor. In the twin-screw extruder 2, two screw rods with interlocking threads are arranged in parallel and rotate in opposite directions. Extrusion die 4 is a circular extrusion disc with several extrusion ports, the hole diam...

Embodiment 2

[0070] The difference between this example and Example 1 is that the formula of the miscellaneous rice is 55% corn flour, 20% sorghum flour, 10% buckwheat flour and 15% water.

Embodiment 3

[0072] The difference between this example and Example 1 is that the formula of the miscellaneous grain rice is 60% of corn flour, 15% of sorghum flour, 15% of buckwheat flour and 10% of water.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com