Energy harvester

An energy harvester and shell technology, applied in the field of energy harvesting, can solve the problems of low output power, low power output, limiting the use range of energy harvesters, etc., to achieve efficient energy harvesting and output, and improve the effect of energy output density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] As mentioned in the background art, most of the current vibration-type energy harvesters are designed with high operating frequencies to obtain high-density energy output, and a few energy harvesters that work in a low-frequency environment have low output power.

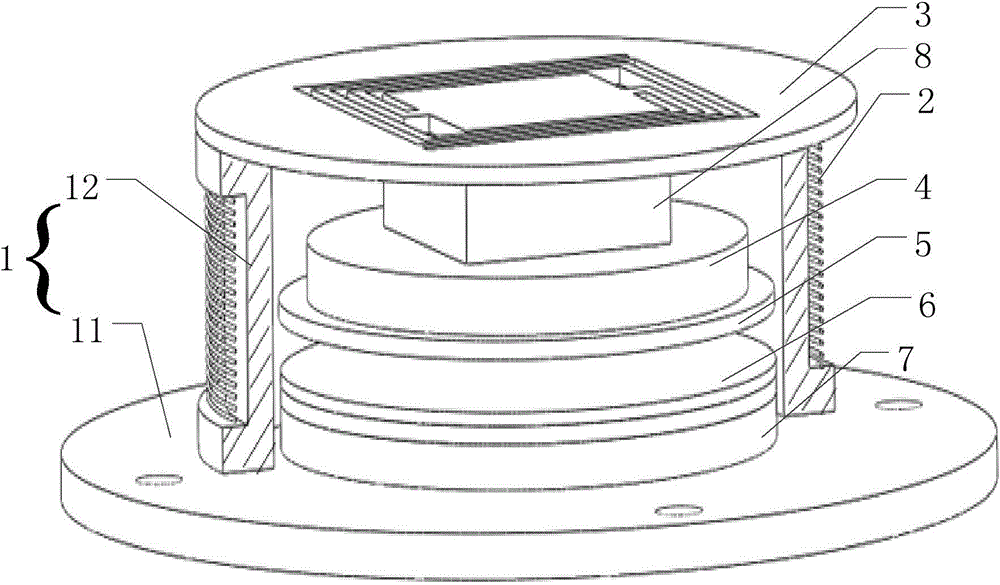

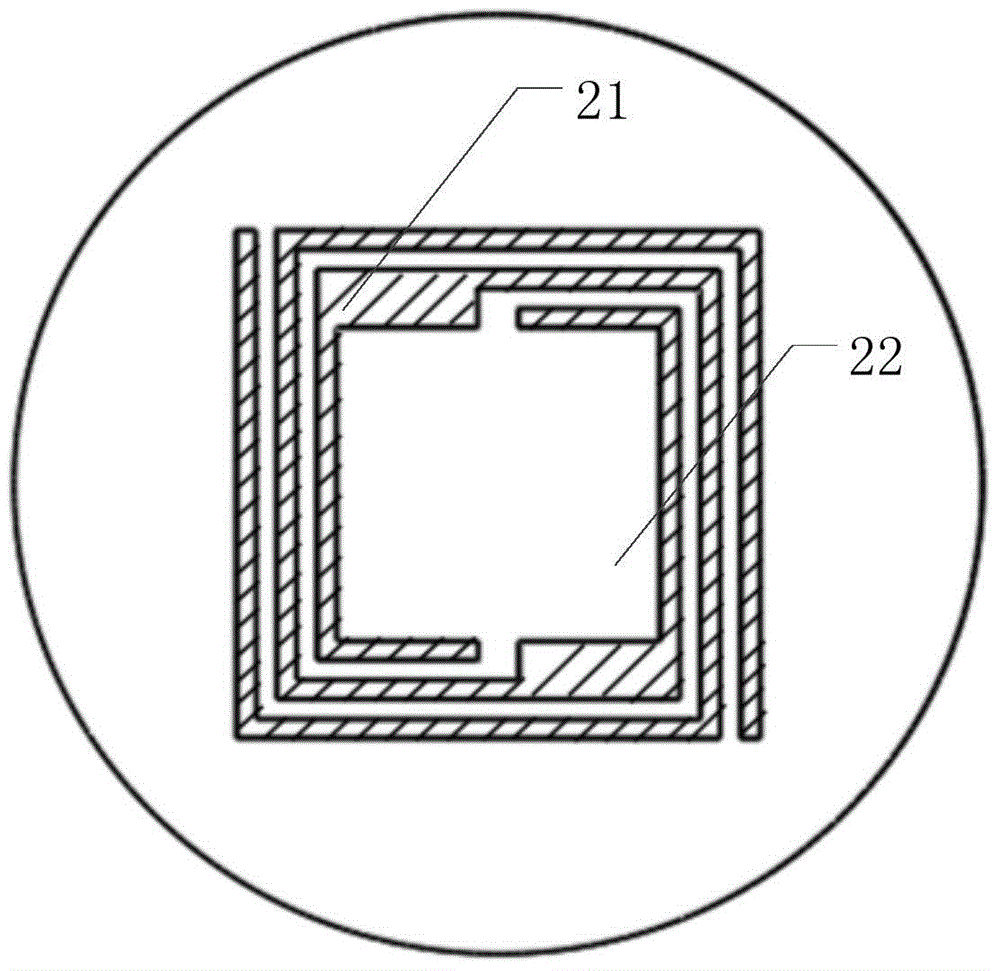

[0031] Based on the above research, an embodiment of the present invention provides an energy harvester, including: an energy harvester housing, the outer side wall of the energy harvester housing is wound with a preset number of coils, and the energy The upper end of the collector housing is provided with an opening; the vibrating plate is provided with a vibrating part responding to external vibrations, the vibrating plate covers the opening at the upper end of the energy collector housing, and the vibrating plate and the The energy harvester housing is fixedly connected; the magnet block is located inside the energy harvester housing, and the magnet block is connected to the vibrating plate; the first friction...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com