Solar cell structure, method for manufacturing same, and solar cell module

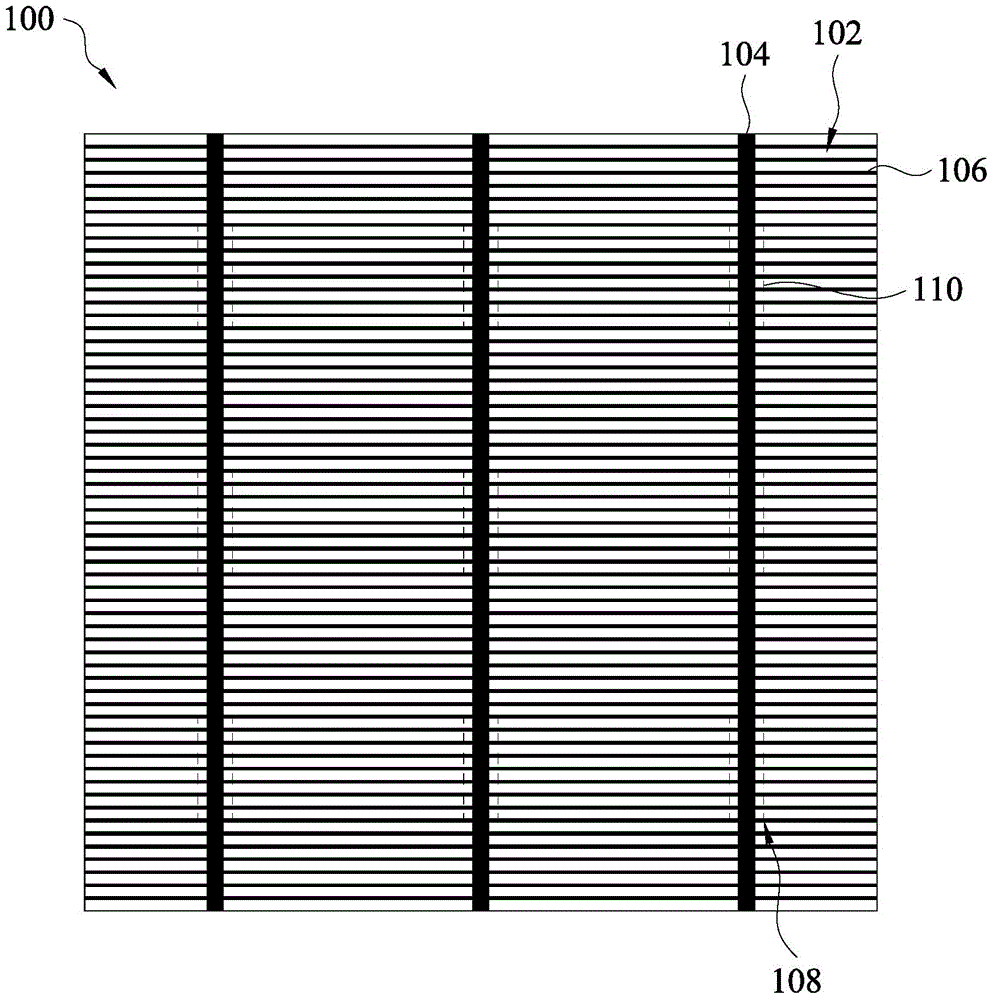

A technology of solar cells and manufacturing methods, applied in the direction of final product manufacturing, sustainable manufacturing/processing, circuits, etc., capable of solving problems such as the decline in output power of solar cells 100 and the inability to transmit current smoothly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

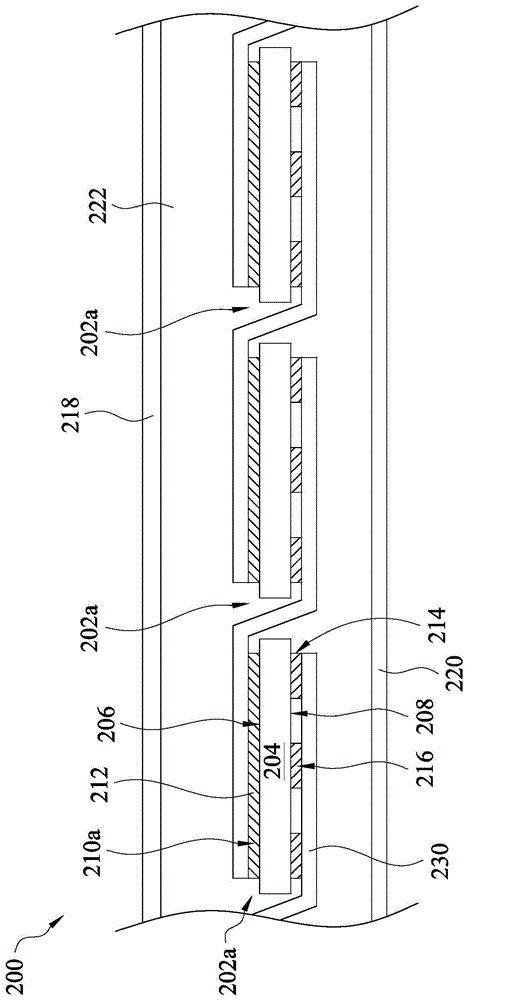

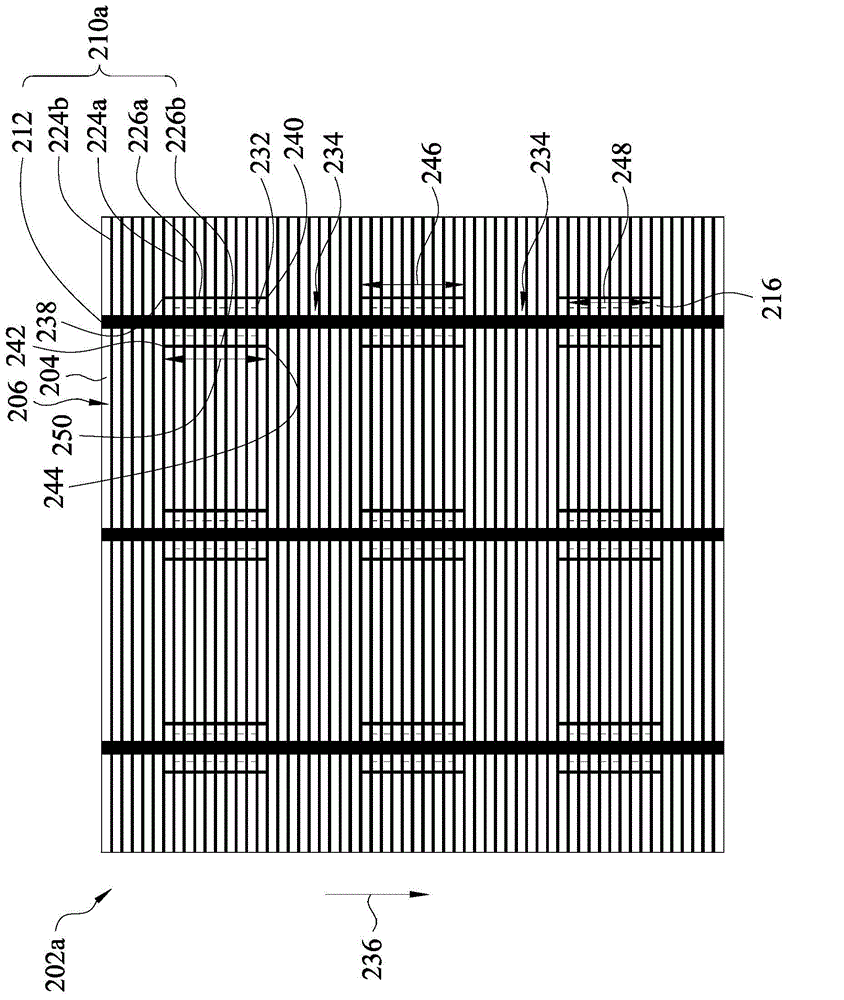

[0031] Please refer to figure 2 , which is a schematic cross-sectional view illustrating a solar cell module according to an embodiment of the present invention. In this embodiment, the solar cell module 200 mainly includes an upper plate 218 , a lower plate 220 , several solar cell structures 202 a , several connecting strips 230 , and one or more packaging material layers 222 .

[0032]In some embodiments, the upper plate 218 is a transparent plate, such as glass. The lower sheet 220 can also be called a back sheet, and the lower sheet 220 can be a white opaque sheet. The solar cell structure 202 a is disposed between the upper plate 218 and the lower plate 220 . The connection strips 230 are also located between the upper plates 218 and 220 , and two ends of each connection strip 230 can be respectively connected to the two adjacent solar cell structures 202 a to electrically connect the two solar cell structures 202 a. The connection strip 230 can also be called a weld...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com