An open-pit blasting ore body boundary loss and dilution control system and operation method

A technology of control system and operation method, which is applied in special data processing applications, instruments, electrical digital data processing, etc., can solve the problem that it is difficult to effectively control the loss and dilution of ore body boundary, time-consuming and labor-intensive blasting in open-pit mines, and affect the economic benefits of mines and other issues, to achieve the effect of improving mine economic benefits, saving manpower, material and financial resources, and simplifying design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0063] The specific embodiments of the present invention will be described in further detail below with reference to the accompanying drawings and examples. The following examples are intended to illustrate the present invention, but not to limit the scope of the present invention.

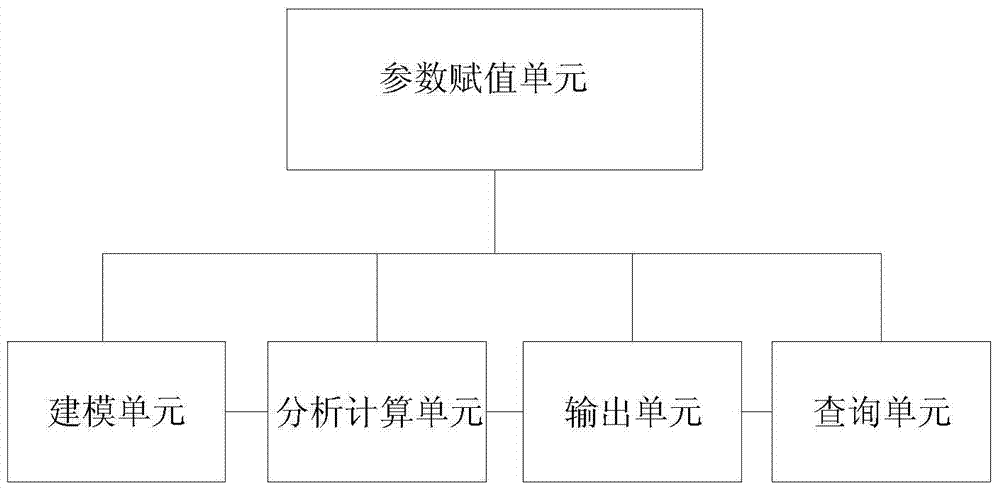

[0064] like figure 1 As shown in the figure, an open-pit blasting ore body boundary loss and dilution control system of the present invention includes a parameter assignment unit, a modeling unit, an analysis and calculation unit, an output unit and a query unit connected in sequence. The modeling unit, the analysis and calculation unit , the output unit and the query unit are respectively connected to the parameter assignment unit, and the query unit includes a mutual query module among the position of the backstroke line, the loss rate and the depletion rate.

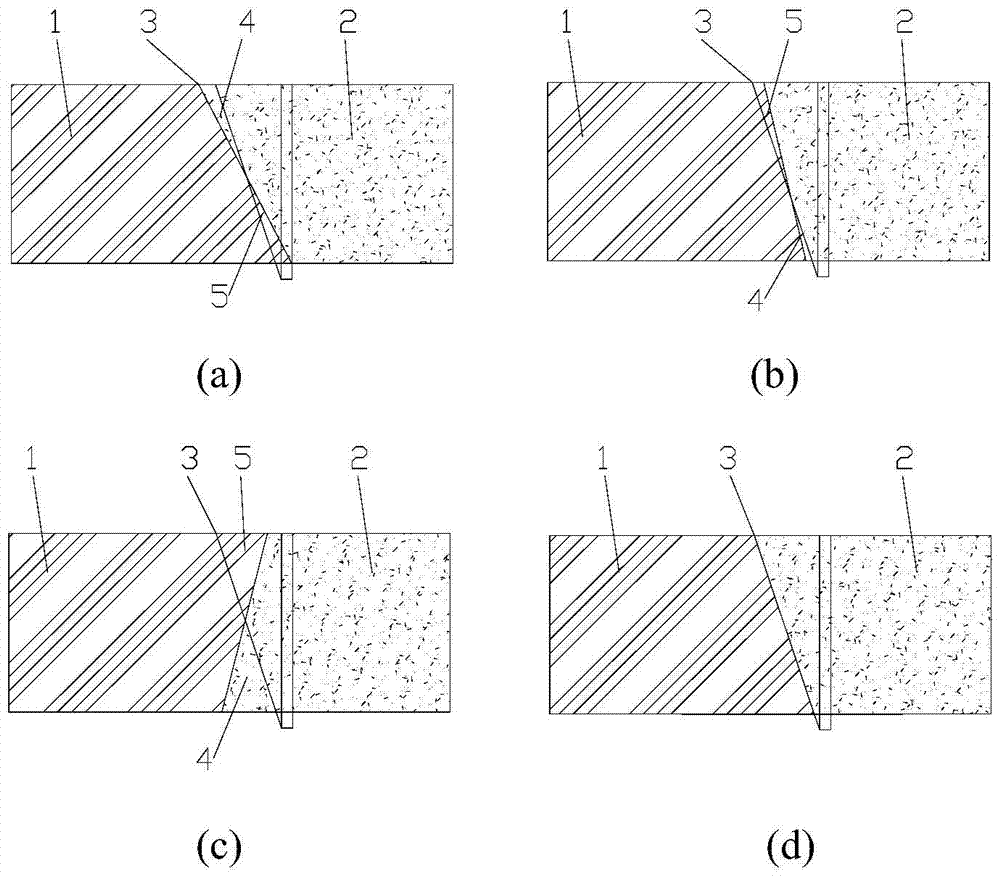

[0065] like figure 2 Figure 2 shows the cross-sectional views of the ore-rock interface and the blasting buffer surface in different ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com