Resin lens capable of emitting fragrance when scrubbed and manufacturing method of resin lens

A resin lens, fragrance technology, applied in the directions of glasses/goggles, optics, instruments, etc., to achieve the effect of easy wiping and maintenance, rich and lasting fragrance, and remarkable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

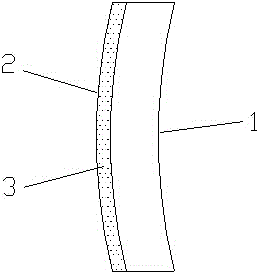

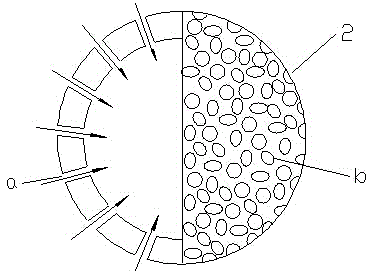

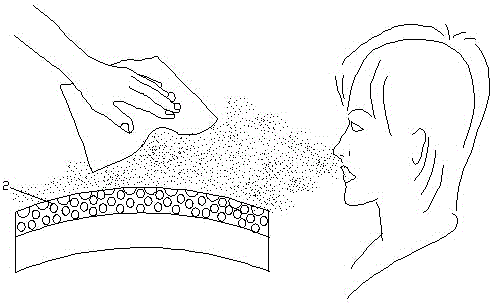

[0022] from figure 1 Known, the present invention a kind of resin lens that emits fragrance when wiping, is made up of resin base sheet 1, nanometer fragrance-dispersing microsphere 2, fragrance plus dura layer 3, is provided with a layer that mixes nano-dispersion fragrance microsphere on the surface of resin lens. The highly transparent nano-silica plus hard liquid of ball 2 is dried and solidified.

[0023] Its processing and manufacturing process is described as follows:

[0024] 1. Making resin substrate 1: Position the lens glass mold on the box-making machine according to the conventional process, wrap the sealing tape around it, inject resin monomer into the mold box, fill the monomer with tape and seal it, and send it to the numerical control for heating The resin substrate 1 was obtained after curing at elevated temperature in the box for 21 hours.

[0025] 2. Making nano-fragrance microspheres 2: Take 5 grams of PGMA hollow microspheres with a particle diameter of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com