Explosive and powder modeling powder free-running property testing method

A technology for modeling powder and explosives, which is applied in the measurement of DC flow characteristics, etc., can solve the problems of low test precision, large and large product differences, relative standard deviation, etc. the effect of the request

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

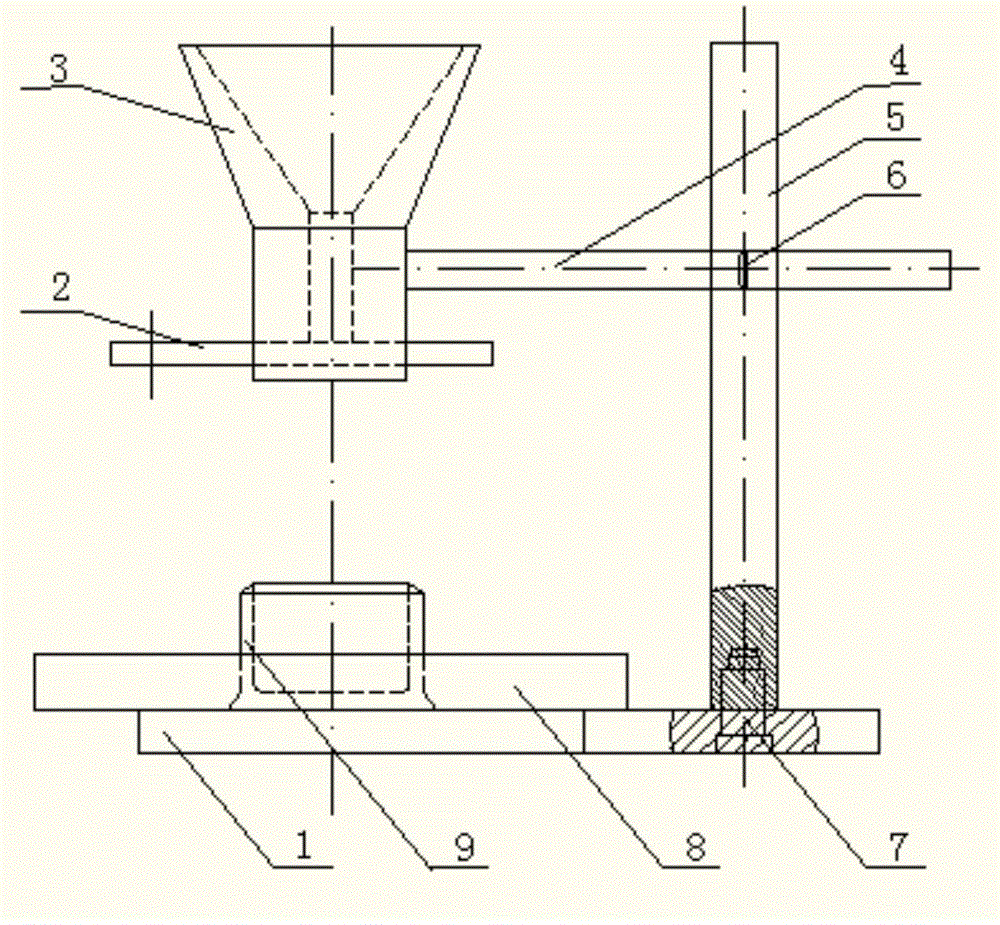

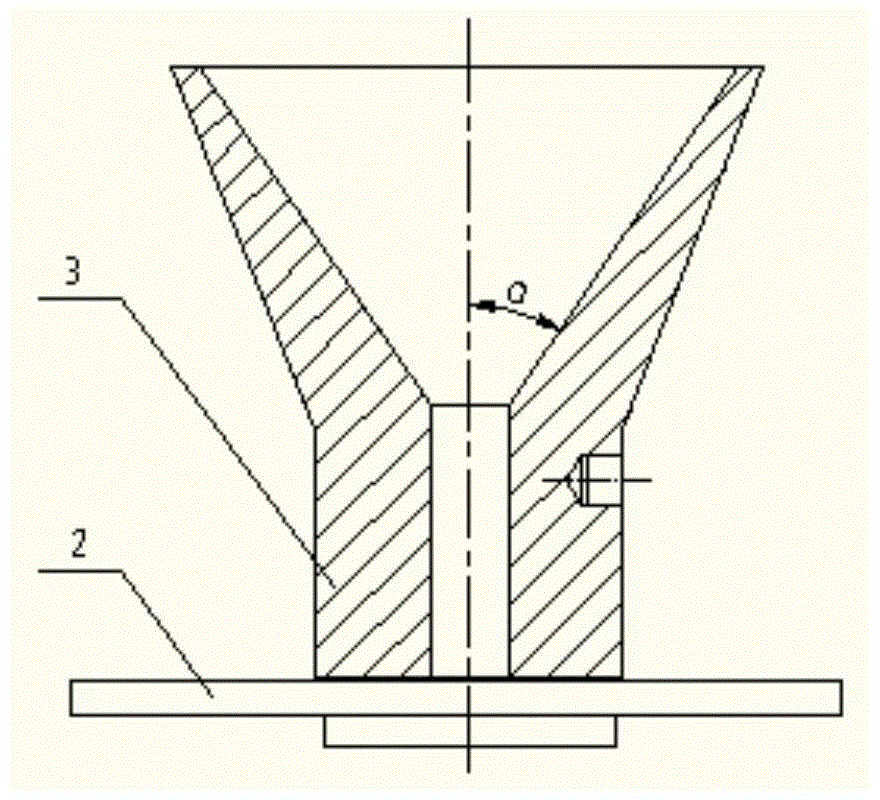

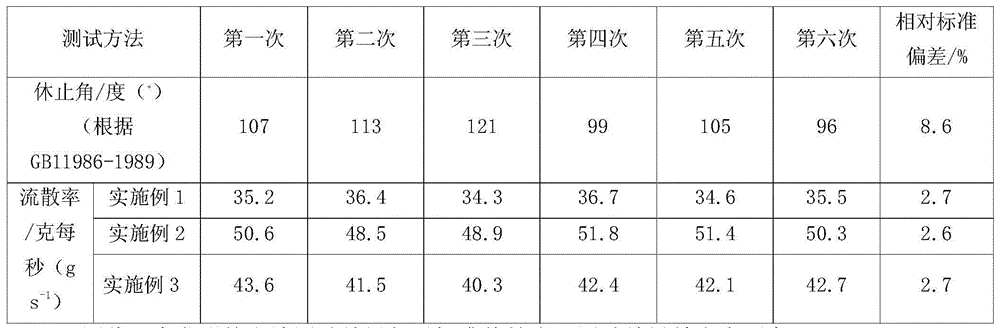

[0015] In the method for testing the fluidity of propellant molding powder, the test device includes a base plate 1, a funnel insert plate 2, a funnel 3, a fixing rod 4, a column 5, a fixing screw 6, an assembly screw 7, a collecting plate 8, and a standard cup 9. The column 5 is vertically fixed on the bottom plate 1 by the assembly screw 7, the fixing rod 4 is horizontally fixed on the column 5 by the fixing screw 6, and the angle is perpendicular to the column 5, the funnel 3 is fixed by the fixing rod 4, placed vertically, and the mouth of the funnel is upward, and the flow The outlet is facing down, the collecting plate 8 is placed under the funnel 3 to receive the modeling powder sample, the funnel insert plate 2 can be inserted vertically into the funnel 3, and is used to control the opening or closing of the outlet of the funnel, and the standard cup 9 is used to determine the shape of the modeling powder sample. volume. It is characterized in that, comprising the foll...

Embodiment 2

[0022] In the method for testing the fluidity of propellant molding powder, the test device includes a base plate 1, a funnel insert plate 2, a funnel 3, a fixing rod 4, a column 5, a fixing screw 6, an assembly screw 7, a collecting plate 8, and a standard cup 9. The column 5 is vertically fixed on the bottom plate 1 by the assembly screw 7, the fixing rod 4 is horizontally fixed on the column 5 by the fixing screw 6, and the angle is perpendicular to the column 5, the funnel 3 is fixed by the fixing rod 4, placed vertically, and the mouth of the funnel is upward, and the flow The outlet is facing down, the collecting plate 8 is placed under the funnel 3 to receive the modeling powder sample, the funnel insert plate 2 can be inserted vertically into the funnel 3, and is used to control the opening or closing of the outlet of the funnel, and the standard cup 9 is used to determine the shape of the modeling powder sample. volume. It is characterized in that, comprising the foll...

Embodiment 3

[0029] In the method for testing the fluidity of propellant molding powder, the test device includes a base plate 1, a funnel insert plate 2, a funnel 3, a fixing rod 4, a column 5, a fixing screw 6, an assembly screw 7, a collecting plate 8, and a standard cup 9. The column 5 is vertically fixed on the bottom plate 1 by the assembly screw 7, the fixing rod 4 is horizontally fixed on the column 5 by the fixing screw 6, and the angle is perpendicular to the column 5, the funnel 3 is fixed by the fixing rod 4, placed vertically, and the mouth of the funnel is upward, and the flow The outlet is facing down, the collecting plate 8 is placed under the funnel 3 to receive the modeling powder sample, the funnel insert plate 2 can be inserted vertically into the funnel 3, and is used to control the opening or closing of the outlet of the funnel, and the standard cup 9 is used to determine the shape of the modeling powder sample. volume. It is characterized in that, comprising the foll...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com