Vehicle hybrid brake system test development testbed

A hybrid braking and system testing technology, applied in vehicle testing, electrical testing/monitoring, machine/structural component testing, etc., can solve the problem of high driving power, EMB system reliability to be verified, and 12V power supply unable to meet usage requirements and other problems, to achieve the effect of compact layout and clear structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Embodiments of the present invention will be described in detail below with reference to the accompanying drawings. It should be noted that the technical features or combinations of technical features described in the following embodiments should not be regarded as isolated, and they can be combined with each other to achieve better technical effects.

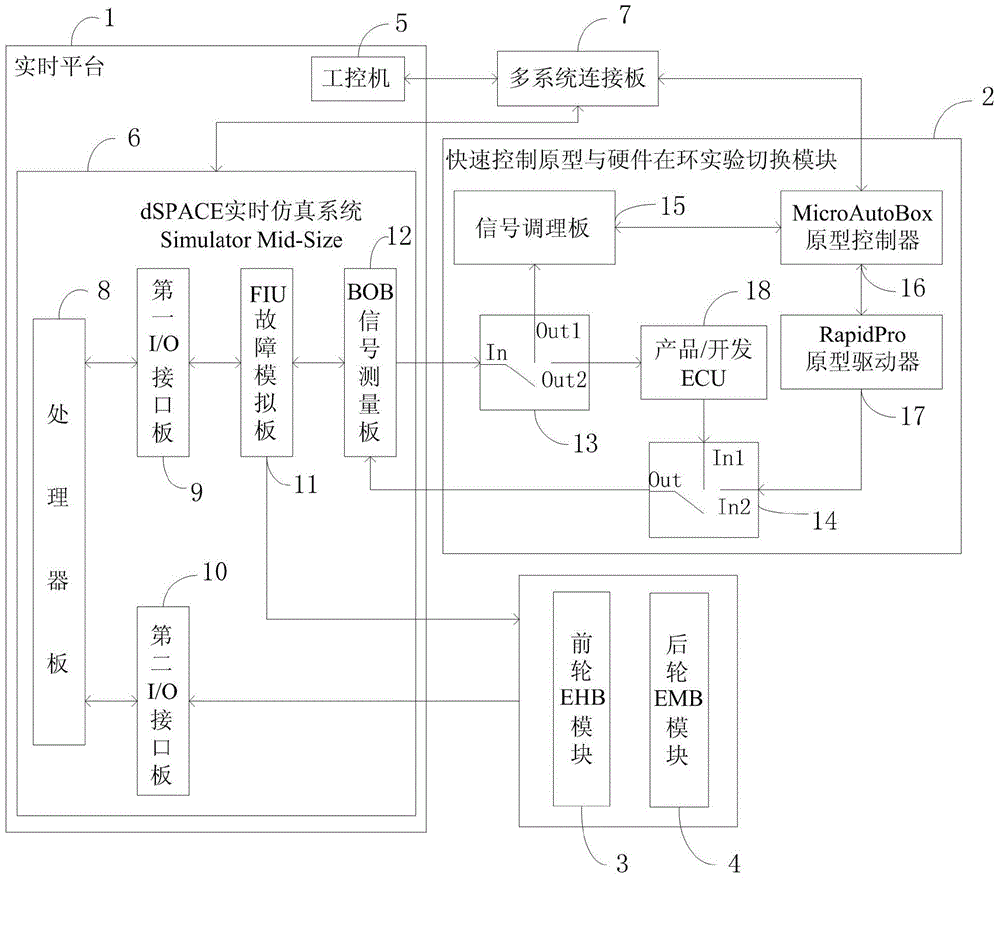

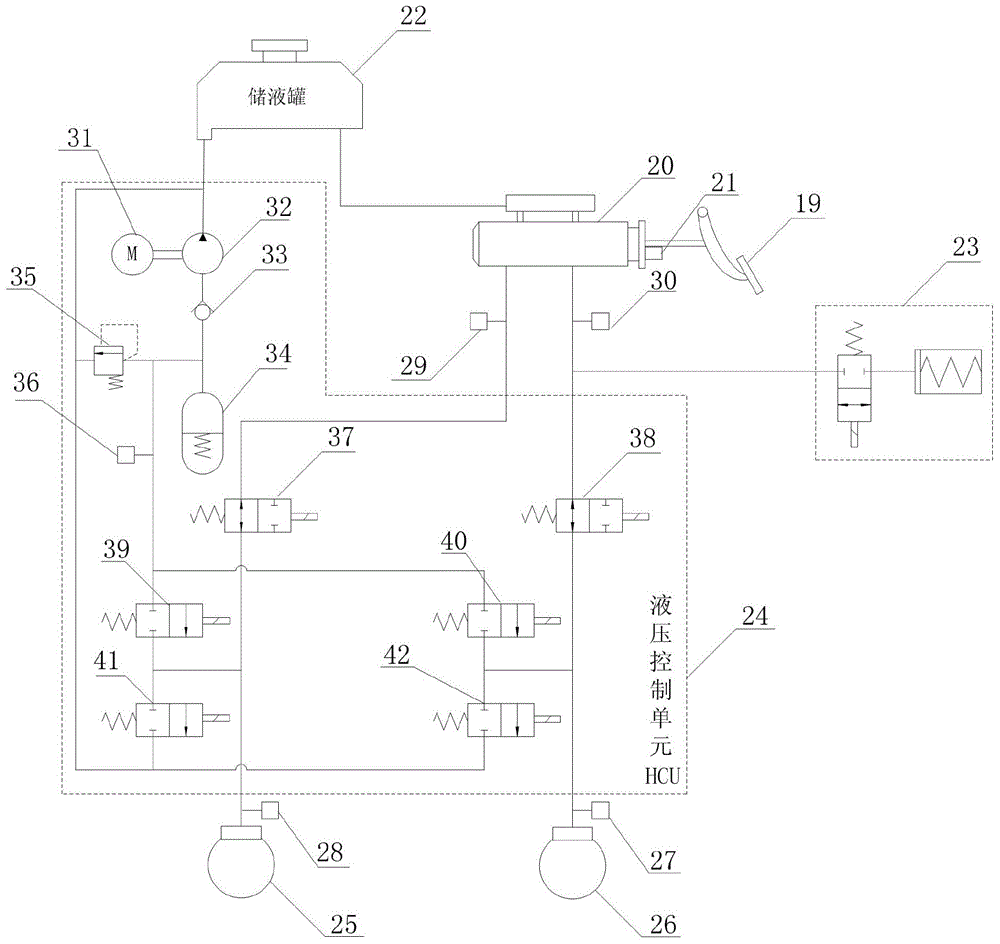

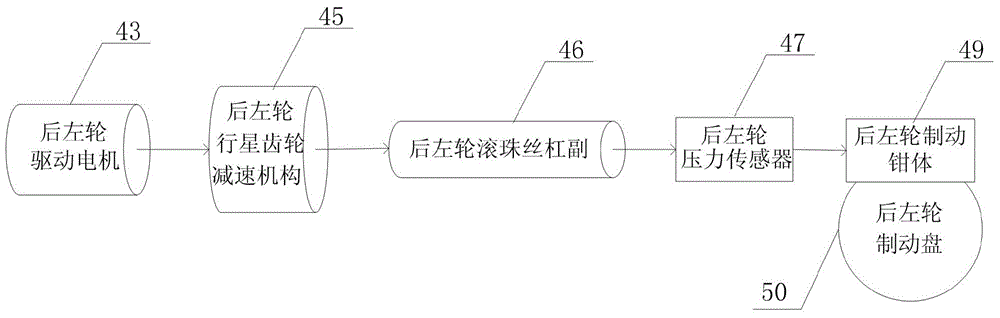

[0025] Such as figure 1 Shown is a vehicle hybrid braking system test and development test bench, including real-time platform 1, rapid control prototype and hardware-in-the-loop experiment switching module 2, front wheel EHB module 3, rear wheel EMB module 4; real-time platform 1 includes industrial computer 5 and dSPACE real-time simulation system Simulator Mid-Size 6; dSPACE real-time simulation system Simulator Mid-Size 6 mainly includes processor board 8, first I / O interface board 9, second I / O interface board 10, FIU fault simulation board 11 and BOB signal measurement board 12, the rapid control prototype and har...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com