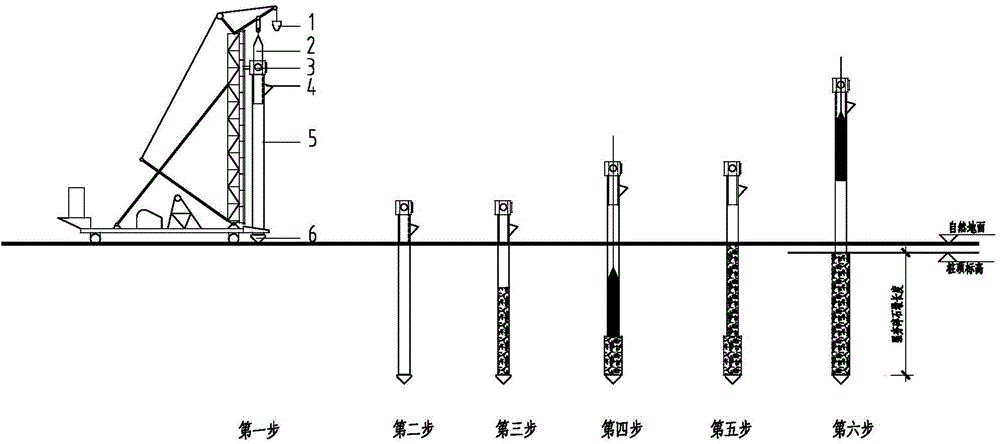

Deep replacement dynamic compaction gravel pile foundation reinforcement method

A technology of foundation reinforcement and gravel piles, which is applied in foundation structure engineering, soil protection, construction, etc., can solve problems such as difficulty in equipment walking, small pile diameter, and poor quality, and achieve good foundation treatment effect and replacement depth Large and good pile effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0035] 1) Level the site and clear underground obstacles to ensure that the site levelness meets the requirements for pile driver construction.

[0036] 2) Experimental construction: Before large-scale construction, a representative site should be selected for pile-forming process tests. During the test construction, construction parameters such as tamping energy, amount of crushed stones, filling coefficient and other construction parameters and the feasibility of pile sinking should be inspected.

[0037] 3) According to the foundation, pile diameter and pile length of the lot, select the appropriate mechanical equipment. A vibratory pile sinker can be used for transformation, with a winch, a gravity rammer, and a secondary feeding port.

[0038] 4) The pile driver is in place: the pile point 6 is placed on the pile position. When the pile driver is in place, the frame must be horizontal and stable, and the pile pipe is vertically aligned with the pile point.

[0039] 5) Vi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com